In the world of automotive enthusiasts, understanding the costs associated with car modifications is essential. From simple aesthetic enhancements to high-performance upgrades, every choice impacts your wallet. Knowing how to budget for these changes can elevate your enjoyment and ensure you get the most for your investment. This article explores the essentials, beginning with common upgrades and their costs, before diving into performance enhancements. We’ll also shed light on luxury customizations and the importance of consultations when planning modifications. Each chapter will equip you with insights necessary to navigate the diverse landscape of car modifications effectively.

Counting Every Bolt: Reading the Real Cost of Car Modifications Across Styles and Setups

Modifying a car is rarely a single decision. It’s a process that blends taste, purpose, and budget into a calculated journey from idea to road-ready reality. The cost of car modifications is not a fixed line; it shifts with the type of upgrade, the vehicle in question, and whether you tackle it with your own hands or bring in a shop. Start with a simple truth: the price you see for parts is often only part of the story. Labor, installation complexity, and the need for supporting work can transform a modest upgrade into a substantial investment. And because every car is different, even two owners chasing the same end result may face markedly different totals. The practical path is to build a clear sense of what you want to achieve, then map that goal to a realistic price range that accounts for both the parts and the process required to install them properly. In this chapter we’ll walk through the common upgrade categories—performance, cosmetics, and interior refinements—and unpack the typical price bands you’ll encounter, while noting the factors that push costs higher or lower. The aim is not to push readers toward or away from any modification but to arm them with a grounded framework for budgeting, planning, and making informed trade-offs. For readers who want a concise synthesis of real-world numbers, there is a well-regarded external overview that consolidates market data and expert input, which serves as a useful reference as you estimate your own project. That resource provides a broader, data-driven picture of how modifications tend to scale in price as you move from bolt-ons to bespoke builds. Returning to the specifics, the landscape breaks down cleanly into a few broad categories, yet the exact price you’ll pay rests on choices that fall into each category. Consider performance upgrades first, the realm where the thrill of enhanced power and response often collides with the reality of higher costs and more involved labor. A cold air intake is a small but instructive example. It’s designed to improve airflow to the engine with a relatively simple installation path. In most cases, you’ll see a price range of roughly two hundred to five hundred dollars for the part itself, depending on the brand, materials, and whether the intake includes a polished finish or a snug, performance-tuned design. The labor story here is typically modest, especially if you’re comfortable with basic wrench work and a quick check of the air intake’s fit and seals. But if your goal is not just a replica of a neighbor’s setup but a carefully tuned system compatible with a broader intake and exhaust strategy, costs can creep upward quickly. Exhaust systems illustrate the same principle in a different light. They range from about three hundred dollars on the low end for a basic cat-back system to around one thousand five hundred dollars for more sophisticated configurations that emphasize flow benefits, sound tuning, and stainless construction. The installation complexity matters. A straightforward bolt-on can be done in a standard garage in a day; more elaborate systems, especially those that require precise alignment with O2 sensors, exhaust hangers, or catalytic components, will likely demand a shop and a few extra hours. For many enthusiasts, the decision to upgrade the exhaust also intersects with sound preference and noise restrictions in daily driving, which can introduce additional considerations and, in some cases, additional costs for resonators or tunings to meet local regulations. When we broaden the scope to forced induction—turbochargers and superchargers—the price picture becomes more dramatic. A turbocharger package, including the core unit, piping, intercooling, and the necessary supporting hardware, plus installation, can easily fall in the range of one thousand to five thousand dollars. In this category, the labor component is a dominant driver because it’s not just bolting on a part; it’s a system integration exercise. It involves tuning the engine control unit (ECU), ensuring fueling systems keep pace with airflow, verifying heat management, and often upgrading the fuel pump and lines to support the increased demand. ECU remapping or tuning itself is typically a five hundred- to two-thousand-dollar line item, depending on how aggressive the tune is, the engine’s baseline tolerance, and how finely the tuning is calibrated to daily-driving reliability versus track performance. Across performance upgrades, the story tends to be the same: parts cost only tells part of the tale, and labor can become the deciding factor for the final total. The same dynamic appears when we shift to cosmetic modifications, where the desire to customize the vehicle’s appearance can attract a broad spectrum of price points. A custom paint job illustrates this spectrum vividly. A simple, modest color refresh may cost a few hundred dollars for a boutique job or a basic respray; however, if you’re chasing a high-end finish with complex graphics, multi-stage clear coats, or specialty pearlescent or matte finishes, the price can stretch into the thousands and, in extreme cases, into the five-figure realm. The paint’s quality and the level of preparation—the sanding, bodywork, dent repair, and coverage demanded by the existing finish—play a central role in determining the final bill. Body kits operate on a parallel axis. A kit can start around a thousand dollars and escalate to five thousand or more, depending on the material (FRP versus carbon fiber), the design complexity, and whether installation requires substantial bodywork or custom fitment. The installation process not only requires precision alignment but may also demand repainting or blending to ensure a cohesive final look. For most enthusiasts, aftermarket wheels are among the most conspicuous upgrades and, perhaps, one of the better-value cosmetic improvements, since wheels can dramatically alter a car’s stance and presence. Price bands for wheels typically run from about five hundred to three thousand dollars per set, influenced by brand, diameter, weight, and finish. The cost of tires, which are often a separate line item, adds a further consideration; even if you source budget tires, the total wheel-and-tire package can push the bill higher than just the wheels alone, especially if you opt for performance or all-season variants designed to match the vehicle’s intent. Steering away from the exterior, interior modifications can deliver a different flavor of value and cost. Premium seat covers or upholstery upgrades can span roughly three hundred to one thousand dollars, depending on material quality, stitching patterns, and whether the upgrade requires a full interior re-trim or a focused enhancement. If you pursue custom stitching or embroidery, the price can climb further into the hundreds or low thousands, driven by design complexity and labor intensity. Upgraded audio systems are a popular interior upgrade that many drivers pursue to improve cabin experience. Depending on the speaker configuration, head unit, amplifiers, and acoustic treatment, the price range can be modest or substantial. A basic, quality-replacement system might sit in the three hundred to one thousand-dollar band, while a more elaborate setup with high-fidelity components and professional installation can push the total into two thousand to three thousand dollars or more. In all these categories, a recurring theme emerges: the cost is not simply about the parts, but about the broader ecosystem that supports them. A part can look inexpensive on the shelf, yet once you factor in compatibility checks, installation time, specialized tools, and potential professional calibration, the final tally can be far higher than the sticker price. There are also practical considerations that quietly shape total cost. Vehicle make and model matter. A modern performance-focused vehicle may invite more sophisticated tuning options that demand higher-precision components and expert calibration, while a simpler, more common platform might accept bolt-on upgrades with straightforward fitment and reliable results. The same upgrade on a high-end luxury model could require more labor and bespoke fittings than on a mass-market baseline, simply because of the tighter tolerances and integration with advanced electronics. DIY versus professional installation is another major fork in the road. The more you take on yourself, the more you save on labor, but the risk of errors rises. An amateur install that later requires rework or professional verification can end up costing more than a clean, professional job from the outset, especially when time is measured in days rather than hours. For some readers, the ideal approach blends the two: tackle straightforward, bolt-on components at home, while outsourcing the more complex or safety-critical upgrades to a trusted shop. In this balanced approach, it is crucial to build in a cushion for unexpected expenses. The road to modification is not always linear; you can encounter hidden costs such as alignment checks after wheel or suspension changes, extra hardware like mounting brackets and fasteners, or the need for updated software licenses and diagnostic services. On the budgeting side, the practical method is to start with a clear goal and then work backward. Define the look or performance target you want, research the components that achieve that target, and then sketch a phased plan that aligns with available funds and the vehicle’s current condition. A product configuration and selection directory—an organized guide that prices options from a catalog of components—can be a helpful compass in this process. It translates design desires into transparent pricing based on vehicle compatibility and the specificity of parts, reducing the guesswork that often accompanies an upgrade path. If you want a quick, direct reference to this kind of structured cost estimation, you can explore a resource that specifically addresses how much car modifications cost in practice. The anchor for this discussion is a concise, widely cited cost overview that breaks down typical price bands and notes the factors that push costs higher or lower. For readers seeking that concise baseline, this link can provide a complementary perspective: how-much-does-car-modification-cost. Beyond the numbers, it’s worth considering the broader implications of modification on ownership. A decision to modify can affect resale value, insurance terms, and even the vehicle’s factory warranty in some jurisdictions. Insurance consequences, in particular, can introduce both cost and coverage adjustments, especially if the modifications change the car’s performance profile or risk rating. Therefore, it is wise to keep a line of communication open with an insurer before embarking on projects that might alter the risk calculus. To the scale of the project itself, the idea of return on investment is key. Some owners chase a specific performance outcome for daily driving, others aim for a personalized aesthetic that endures through seasons and trends, and a few pursue a blend of both. In the end, the sum of parts, the labor you’re willing to invest, and the alignment with your vehicle’s overall architecture will determine whether a modification feels like a smart spend or an aspirational splurge. For readers who want to ground their budgeting in data and real-world experience, it’s helpful to reference a comprehensive, externally sourced breakdown that aggregates typical costs across categories and vehicle types. This external resource offers a broader, data-driven picture of how modification costs scale with different upgrade paths, and it complements the practical, hands-on insights shared here. You can consult that guide to widen your understanding of cost ranges as you map your own build. External resource: https://www.caranddriver.com/features/a59378466/car-modification-costs/”

Power, Price, and Practicality: The Real Cost of Engine and Exhaust Upgrades

When car enthusiasts think about performance upgrades, the focus often lands on horsepower numbers and the satisfying soundtrack of a tuned exhaust. Yet the true price of engine and exhaust enhancements stretches far beyond sticker price. It is a conversation about ambition meeting feasibility, where the intent of the build—street confidence, track capability, or a balanced daily driver—shapes every dollar spent. Engine and exhaust work sits at the crux of performance and reliability, and the costs reflect not only the parts themselves but the complexity of installation, the need for supporting systems, and the risk calculus tied to pushing a engine to new limits. As of early 2026, the practical cost landscape can be understood along a broad ladder, from modest, sound and efficiency tweaks to entire powertrain evolutions. This spectrum matters because your expectations steer the budget, and your choices determine how much horsepower, torque, and usable performance you actually gain while maintaining daily drivability and long-term reliability.

At the most accessible end, basic exhaust and engine tweaks offer a clear pathway to a more satisfying driving experience without a fortress-like wallet. A straightforward exhaust upgrade—think a higher-flow system designed to improve exhaust flow and breathing—typically lands in the several hundreds to a few thousand dollars range. These systems usually include upgraded piping, a more free-flowing muffler, and sometimes a high-flow catalytic converter. The intent is to reduce backpressure and unlock a more responsive throttle, with the caveat that the gains are modest and highly dependent on the vehicle’s baseline tuning and CAN integration. It’s not uncommon to see gains measured in the low tens of horsepower when paired with supportive changes like a tune, especially on turbocharged or high-compression engines. For the DIY-minded, the cost spread can be even tighter, but labor considerations quickly push the project into the realm where professional installation makes more sense for a clean, safe outcome.

Engine enhancements in this entry-level tier often include simple, affordable components that are compatible with a broad range of engines. Upgrades such as performance spark plugs, a cold-air intake, or other ignition and intake components provide incremental improvements. In terms of price, these minor upgrades are typically affordable—often under a thousand dollars in total—yet they create the foundation for more substantial gains later. For example, an iridium-tipped plug set might cost a few hundred dollars, while upgrading ignition components could add a similar amount. The net effect is not fireworks but a more efficient engine breathing and more consistent ignition under higher load. The key is realism: modest upgrades are a step toward improved efficiency and a more assertive feel without crossing into the high-stakes territory of major engine work.

As you ascend to intermediate upgrades, the price structure shifts—and with it, the potential for meaningful performance gains. ECU tuning becomes a central piece of the puzzle. A professional tune can unlock engine maps that better exploit the upgrades already on the vehicle, whether that’s a freer intake, a higher-flow exhaust, or a revised ignition timing strategy. Tuning costs vary based on the complexity of the vehicle and whether the tuner has to work with a baseline calibration or a fresh, bespoke map. Typical ECU tuning falls roughly in the $800 to $2,500 range, depending on the sophistication of the software, the number of parameters adjusted, and whether the tune includes drivability refinements and data logging. In parallel, performance camshafts or lightweight rotating components—such as a lighter flywheel—add to the budget, often in the few hundred to a few thousand dollars per item. The appeal of this tier lies in the compounding effect: a well-executed tune can unlock the full potential of a well-chosen intake and exhaust pairing, delivering a more immediate throttle response, crisper power delivery, and improved peak power. Yet with greater capability comes greater risk, especially if cooling, fueling, and drivetrain components are not upgraded in tandem.

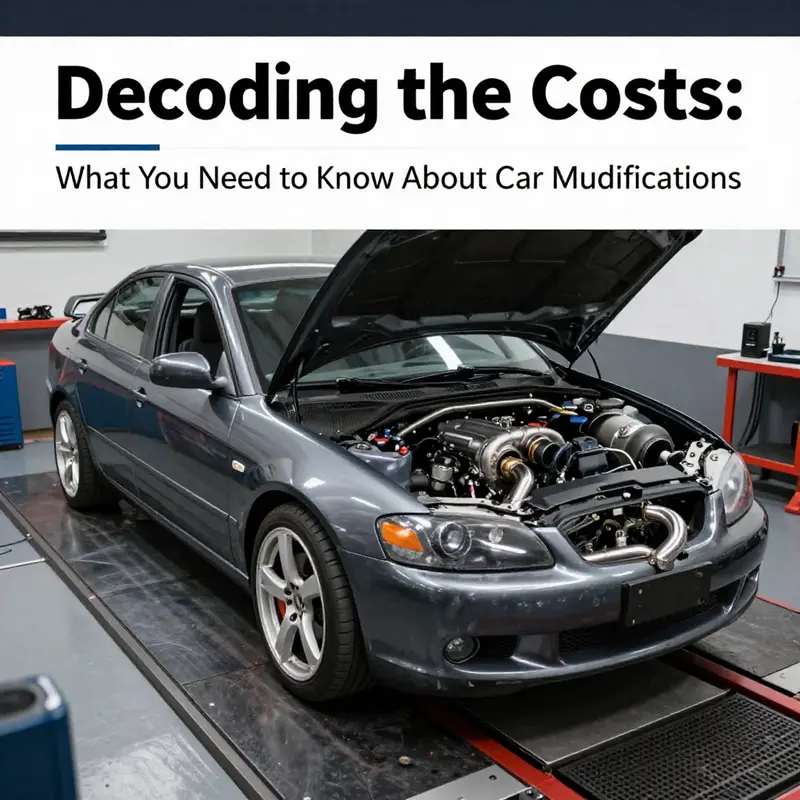

The cost picture becomes even more nuanced when you approach major engine modifications. Here the conversation shifts from incremental improvements to transformative, power-focused alterations. Forced induction kits—turbochargers or superchargers—mark a distinct milestone. Bodied in the language of drama and performance, these kits often require accompanying upgrades to fuel delivery and engine internals to handle the increased air and pressure. The hardware alone typically starts in the mid five-figure range for more sophisticated setups, with prices commonly climbing into the five- to twelve-thousand-dollar territory or higher for the kit alone. Installation expenses, ECU work, intercooler plumbing, fueling system upgrades, and the added need for robust cooling systems push total project costs well beyond the price tag of the core kit. It is not unusual for a complete forced induction build or a comprehensive engine refresh to approach or exceed twenty thousand dollars when you include labor and supporting modifications. In some cases, especially for high-end or exotic platforms, the total can be substantially higher, reflecting the bespoke nature of the work, the scarcity of parts, and the meticulous calibration required to extract meaningful, reliable power.

Even the most aggressive power ambitions come with a practical caveat. Labor costs for installation can be substantial, often ranging from about $1,000 to $5,000, depending on the complexity of the work, the shop’s rate structure, and the time required to properly install, wire, tune, and test the modification. A thorough build—where multiple elements are upgraded in concert—often demands a phased approach. Shops may recommend evolving the project over weeks or months, with interim steps ensuring drivability and reliability at each stage. The cumulative labor hours over a broader project can push costs higher than the raw parts bills, underscoring the importance of a detailed road map and a contingency buffer in the budget.

Beyond the pure parts and labor, the entire enterprise hinges on a network of supporting systems that must be upgraded or at least evaluated to handle the new power levels. Upgraded cooling is a frequent requirement in higher-performance builds. Without adequate cooling, the engine can misfire or pull timing, undermining performance gains and potentially harming long-term durability. Upgraded fuel delivery, including pumps and injectors sized to the new air-volume, is another common necessity to maintain safe air-fuel ratios under higher boost or improved throttle response. Similarly, transmission components, clutch upgrades, and torque management measures often need attention to cope with the extra stress. While these support systems add to the bill, they are critical for ensuring that the power increases translate into real-world performance rather than ephemeral peak numbers with compromised reliability.

Regional variations add yet another layer of complexity. Taxes, import duties, and local emissions regulations can drive up the cost or constrain certain parts in specific markets. In some regions, certain performance parts may require emissions-compliant designs or additional testing, which can add months of delay and several thousand dollars to the project. The regulatory landscape, while not a barrier in every case, remains a real factor for those pursuing high-performance builds. The practical takeaway is to begin with a clear scope and to consult a reputable customization shop that understands local rules and can propose compliant options that deliver the desired feel without unexpected conflicts on the road or at the inspection station.

In weighing these options, many builders also consider resale value and long-term maintenance. Modifications can influence resale value in different directions. A well-done, properly documented, and reversible upgrade with good tuning can enhance appeal to a specific buyer pool. Conversely, highly specialized or aggressively tuned configurations may limit buyer interest or require additional investment to maintain. Maintenance costs tend to rise with higher performance because components wear more quickly when pushed beyond stock tolerances. A comprehensive plan that includes a budget for routine checks, inspections, and potential part replacements helps protect the investment. The best path often starts with a realistic assessment of how the car is used. If daily driving and reliability are paramount, the plan may favor balanced, well-supported upgrades rather than a high-cost, single-peak peak-power strategy.

To ground these abstractions in real-world practice, it helps to reference broad industry trends and practical pricing guidance. The numbers cited above reflect a spectrum observed in typical markets: a basic exhaust or intake upgrade can stay under a thousand dollars; a more advanced intake-plus-tue tune approach tends to hover in the low-to-mid four figures; and major engine work, especially when it includes forced induction and a complete supporting package, frequently surpasses the ten-thousand-dollar mark and can escalate significantly from there depending on the vehicle and the sophistication of the setup. In practice, most enthusiasts pursue a staged plan: acquire a clear objective, start with a modest upgrade, evaluate the driving feel, and then decide whether to pursue further enhancements. This iterative approach reduces the risk of misalignment between expectations and outcomes and helps manage the financial commitment.

For readers seeking to anchor their budgeting with real-world baselines, it is useful to consult sources that aggregate expert opinions and typical price ranges. While the specific pricing can vary, a broad reference framework is widely recognized: base performance components tend to be affordable enough to entice experimentation, but the most compelling gains demand a coherent plan that includes tuning, cooling, fueling, and drivetrain reinforcement. The interplay between parts, labor, and the skill of the technician will always shape the final bill. And while the prospect of more horsepower is alluring, prudent builders emphasize drivability and reliability as the true measures of a successful upgrade. In this light, the journey from modest improvements to a full-blown powertrain transformation is not merely a matter of appetite but of disciplined budgeting and thoughtful engineering.

For readers who want a practical starting point with a more concrete view of typical costs, this guide provides a grounded overview of common price ranges and the logic behind them. It is also worth noting the broader ecosystem that supports engine and exhaust performance: manufacturers and aftermarket suppliers offer configuration tools and catalogues that let you preview how different combinations might align with your vehicle and goals. A well-vetted shop can help you translate a desired horsepower target into a feasible, cost-conscious plan that preserves daily usability while delivering meaningful performance. If you are starting from scratch and evaluating whether to pursue an upgrade, it is prudent to identify your most important outcome—sound, throttle response, track capability, or sustained high-rpm stability—and work backward to a budget that accommodates the necessary supporting work and a realistic maintenance outlook. For a practical baseline of typical costs drawn from real-world data and expert analysis, you can explore this guide on how much car modification costs how much does car modification cost.

In sum, the cost of engine and exhaust upgrades is not a single number. It is a layered calculation that grows with ambition—from simpler, incremental improvements to sophisticated, multi-component builds. A modest upgrade path may deliver an appreciable driving improvement for a few thousand dollars, especially when paired with a tune. A mid-range plan, with a careful blend of breathing, fueling, and mapping upgrades, can land in the several-thousand-dollar territory but still remain within reach for committed enthusiasts who treat it as a staged project. The most ambitious undertakings, which seek substantial power gains and the associated performance envelope, require careful budgeting that includes robust labor, advanced fabrication, and a suite of supporting modifications to maintain reliability and drivability. The key to a successful, satisfying outcome lies in a precise, reality-grounded plan: define goals, map the interdependencies of parts and systems, anticipate the cost of installation and tuning, and reserve a cushion for the unexpected. Only then can you translate the dream of elevated performance into a workable, enjoyable reality that does not outpace your appetite—or your wallet.

External reference: https://www.caranddriver.com/features/a59378466/car-modification-costs/

The Prestige Price Tag: Decoding Luxury Car Modifications and Their True Costs

The chapter begins not with a price list but with a story about desire, craftsmanship, and the stubborn reality that every choice in a luxury modification carries a consequential price. When car enthusiasts speak of bespoke interiors, carbon-fiber bodywork, or integrated smart systems, they are describing more than aesthetics or speed boosts. They are describing a commitment to a personalized vision that must endure the test of time and road use. In this space, cost is not merely the sticker price of a component. It is the byproduct of material innovation, meticulous labor, and a design process that treats a car as a moving sculpture rather than a static object. The numbers, then, reflect not only the parts but the journey: design ideation, sourcing, testing, and the careful calibration that ensures a vehicle remains safe, drivable, and compliant with performance standards.

Luxury customization sits at an intersection where artistry meets engineering. In practice, it means balancing the allure of rare materials with the realities of fitment, durability, and the daily demands of a vehicle used in real-world conditions. Hand-stitched leather interiors, carbon fiber body kits, and integrated smart systems are emblematic of this balance. Each feature represents a decision: what level of tactile luxury is worth a corresponding rise in price, and how much performance, tech, or endurance will the car user demand over years of ownership? The costs associated with these choices are rarely linear. They compound as engineers and artisans must coordinate across multiple disciplines—interior design, exterior aerodynamics, powertrain optimization, electronics, and software integration.

A comprehensive view of the luxury segment in 2026 reveals a market growing steadily as buyers seek both exclusivity and performance. Wealthier buyers are not just paying for a product; they are paying for a promise: a vehicle that feels unique, performs beyond stock capabilities, and carries a narrative of tailored craftsmanship. This growth translates into pricing dynamics that can surprise even seasoned enthusiasts. The most meaningful costs in luxury customization arise from three intertwined drivers: premium materials and finishes, the labor of highly skilled specialists, and the precision required to ensure that every modification works in harmony with the vehicle’s base architecture. The leather that feels like a bespoke suit, the carbon fibers that replace standard panels with featherweight rigidity, and the sensors and control modules that knit together new capabilities all add up to a total that can significantly exceed the cost of many mass-market upgrades.

Consider the interiors first. Hand-stitched leather, a hallmark of luxury, is not merely about the texture or color. It demands expert seamwork, rare hides, and careful treatment to prevent wear over thousands of miles. The price range for a substantial interior upgrade typically starts in the mid tens of thousands and can easily climb higher when the customization session includes custom dashboard veneers, seat geometry revisions, and bespoke instrument clusters. The tactile experience—woven leather accents on door panels, reinforced seams along high-contact areas, and cabin scent or ambient lighting schemes designed to align with the owner’s preferences—takes time and artisan skill to execute. Those hours translate into labor costs that are distinctly separate from the cost of raw materials.

Exterior enhancements tell a parallel story. Carbon fiber body kits, aero components, and precision-painted finishes bring together performance and aesthetics. Carbon fiber, prized for its lightness and strength, commands a premium. A full carbon fiber kit—covering spoilers, diffusers, side skirts, and fenders—can push the price into the upper tens of thousands, with higher-end kits and bespoke finishes climbing well into five figures or more. Coupled with a refined paint process and protective coatings, the exterior package becomes a multi-layered investment. Even when the raw materials are lighter and sometimes more costly, the real factor driving up costs is the integration work: ensuring that aero components align with the car’s chassis, that mounting points are reinforced where needed, and that the surface finish remains impeccable under dynamic loads and long-term exposure to the elements.

Meanwhile, the integration of advanced systems adds a distinctly modern dimension to the luxury equation. Integrated smart systems can include redesigned infotainment interfaces, bespoke digital clusters, sensor suites for driver assistance, and connectivity enhancements that weave the vehicle into a broader digital ecosystem. Each system upgrade is not simply a software patch. It requires custom harnesses, certified modules, shielding against interference, and rigorous testing to confirm compatibility with the factory electronics. The result is better functionality at the cost of time and engineering effort. The more ambitious the system integration, the more the project resembles a small-scale engineering program rather than a standard aftermarket installation.

The financial calculus becomes even more nuanced when one considers the role of regional factors and global sourcing. Regions that have developed sophisticated, technology-driven customization ecosystems can deliver breakthroughs in cost and capability. For instance, certain technology-forward manufacturing hubs in Asia have built supply chains that deliver advanced, integrated components at prices significantly lower than traditional luxury markets. The availability of automation, precision manufacturing, and scalable labor can reduce per-unit costs by substantial margins—often cited in the range of 30–50% when comparing comparable design-and-build efforts across different regions. Yet this advantage does not erase the fundamental costs of luxury customization. It shifts them. Owners still face substantial bills for skilled labor, prototyping, calibration, and safety validation. The total investment remains a premium experience because it reflects the combination of exclusive materials, exacting engineering, and the time needed to bring a bespoke design from concept to road-ready form.

To understand the magnitude, one must imagine the project as an orchestration rather than a checklist. It begins with a concept room, where the client’s tastes are translated into a design brief. Then, engineers draft tolerances, material specifications, and integration schematics. Prototyping follows—a period during which small-scale models or panel sections are built and tested for fit, weight, and aesthetics. After refinement, the final components go into production with exacting standards for tolerances, surface finishes, and interface compatibility. These steps require a cadre of specialists: upholsterers, metalworkers, precision machinists, electrical engineers, software developers, and calibration technicians. Each professional brings a unique rate, and each stage introduces its own risk of delays or rework, which translates into additional costs. It is this convergence—design, prototyping, testing, and full integration—that often determines whether a luxury modification feels coherent or carries the risk of mismatched performance, reliability issues, or warranty concerns.

Beyond parts and labor, safety and compliance emerge as non-negotiable contributors to the price tag. A high-end project may necessitate certification processes, safety testing, and performance validations to ensure that the vehicle remains compliant with local road standards and regulatory requirements. These measures are necessary not only for legal reasons but to protect the owner against liability in the event of accidents or component failures. The risk management aspect matters deeply in luxury work because even a minor misalignment or calibration drift can affect braking balance, steering response, or airbag system performance. The cost of thorough testing—on dynamometers, test tracks, or simulated environments—adds a prudent layer of expense that cannot be easily priced away in a simple parts-and-labor estimate.

What drives the final price, then, beyond materials and labor? It is the decision to pursue a highly personalized outcome that emphasizes performance, exclusivity, and long-term ownership value. The scale of the project influences the pricing structure. A tasteful interior refresh with upgraded materials might sit in a predictable price band, while a full-scale, multi-year transformation—encompassing exterior aerodynamics, powertrain adjustments, complete interior redesign, and advanced electronics—becomes a multi-hundred-thousand-dollar proposition. Even when a client’s ambition is to maintain everyday usability, the undertaking remains a premium proposition because it redefines the car’s character, not merely its capabilities.

In this context, the notion of value takes on a broader meaning. Value is not only what the work costs upfront but also how it enhances the vehicle’s appeal, how it affects maintenance and usability, and how it shapes ownership experiences over time. A well-executed luxury customization can elevate resale value when it aligns with the buyer’s tastes and when the installation is presented as a curated, verifiable upgrade rather than a hardware swap. Yet the opposite is also true: if a modification is perceived as excessive or incompatible with the vehicle’s design philosophy, it can complicate resale, reduce market appeal, or trigger concerns about reliability and insurance implications. That is why many enthusiasts choose to document the customization journey, providing a transparent record of parts, labor, testing, and calibration. Such documentation helps prospective buyers understand the scope of work and the care invested, which can translate into more confident negotiations and a fairer assessment of the vehicle’s premium status.

To bring the discussion back to pricing discipline, it is worth considering how buyers navigate the luxury segment. The decision to invest in extensive customization is rarely a one-off impulse. It often follows a thorough evaluation of the car’s base capabilities, the performance and aesthetic enhancements available, and the owner’s long-term fabric of use. The initial price tag is rarely the end of the story. Maintenance, service intervals, and possible future upgrades all contribute to the total cost of ownership. Owners must weigh whether the enhanced experience justifies ongoing costs—such as specialized servicing, guaranteed warranty coverage for modified components, and potential insurance adjustments. The relationship between cost and value here is not purely monetary. It is also about the assurance that the vehicle remains reliable, enjoyable, and coherent with the owner’s vision years after the modifications are completed.

For readers who are curious about concrete figures, the luxury customization sector shows a broad spectrum. Simple enhancements—like premium interior trim or upgraded wheels—cast a wide but still premium net, often ranging from the mid-thousands to tens of thousands. More ambitious attempts—such as carbon fiber aero packages, high-end sound systems with bespoke tuning, or full interior overhauls—tend to fall in the upper tens of thousands and can easily exceed six figures when paired with engine or suspension enhancements. A cautious, well-planned luxury build may hover in the six-figure territory, while the most exhaustive and individualized programs, especially those combining exclusive materials, state-of-the-art electronics, and bespoke engineering solutions, can approach or surpass the seven-figure mark in rare cases—though such projects are exceptional and highly niche. The message here is not to sensationalize but to acknowledge the real scale of investment that some clients willingly pursue in the name of personal expression, performance, and lasting differentiation.

As with any high-stakes venture, buyers in this space often seek guidance to avoid missteps. The best approach is a collaborative process with a respected customization shop or a team that can translate aspirations into a coherent plan with clear cost roadmaps. This is where a product configuration mindset—where options are priced transparently and tested for compatibility—proves invaluable. It helps the client see how incremental choices impact overall cost and, importantly, how each choice interacts with safety, warranty, and regulatory requirements. The value of such a partnership goes beyond the final look or the last horsepower figure. It lies in the confidence that the project remains executable within practical constraints and that the final vehicle will perform as promised without compromising dependability or daily usability.

To close the loop on the broader context, luxury customization sits within a market that recognizes the premium value of individualized engineering and artistry. The decisions buyers make about materials, labor, and system integration are inseparable from the car’s identity and how it is perceived by the world. This is why the price tag of luxury modifications is often described not in a vacuum but as a reflection of a confluence: the owner’s personal narrative, the vehicle’s engineering DNA, and the evolving capabilities of contemporary automotive technology. In such a landscape, a well-conceived modification program offers more than a new look or a few extra horsepower. It provides a tailored experience that respects the car’s heritage while projecting a future-ready character. Those who embark on this path are choosing to invest in a vehicle that embodies their taste, their standards for craftsmanship, and their belief that performance and beauty can coexist in harmony—albeit at a price that matches that conviction.

For readers seeking practical guidance on pricing and planning, a useful starting point is a broader discussion that aligns with the broader article topic: how much do car modifications cost. See further discussions on typical ranges and practical planning in related resources such as how-much-does-car-modification-cost. This context helps frame the luxury segment not as an isolated indulgence but as part of a continuum that ranges from tasteful upgrades to comprehensive, high-end transformations. Understanding where your project sits on that continuum is essential to setting expectations and achieving a satisfying result without misallocating resources.

External reference: https://www.marketsandmarkets.com/Market-Reports/luxury-custom-car-market-45759.html

null

null

Final thoughts

Navigating the world of car modifications comes with its own set of challenges, primarily stemming from the associated costs of upgrades. Understanding the broad price ranges—from simple aesthetic tweaks to high-end luxury customizations—allows enthusiasts to make informed decisions that suit their budget and aspirations. Whether you’re enhancing performance through engine tuning or making your classic car a unique showpiece, each modification carries a price tag that reflects the craftsmanship involved. Therefore, a thoughtful approach to budgeting, planning, and consulting with professionals can lead to a satisfying and rewarding modification journey.