For car enthusiasts, the allure of personalizing one’s vehicle through Do-It-Yourself (DIY) modifications is unparalleled. These modifications don’t only enhance a car’s performance but also reflect the owner’s unique personality and driving style. In a world where automobiles are often seen as merely tools for transport, DIY mods allow individuals to transform their cars into expressions of creativity and engineering prowess. This article dives into four integral chapters aimed at guiding hobbyist car modifiers, professional tuners, classic car restoration enthusiasts, global modification fans, and auto parts suppliers. We begin with essential tools and techniques that lay the groundwork for successful modifications. Next, we delve into performance enhancements that promise increased power, before exploring aesthetic upgrades that take a vehicle’s visual appeal to the next level. Finally, we underscore critical safety considerations to ensure that the journey remains enjoyable and secure. Each chapter intertwines to provide a holistic understanding of DIY car modifications, creating an enriching experience, whether you are just starting out or looking to deepen your knowledge.

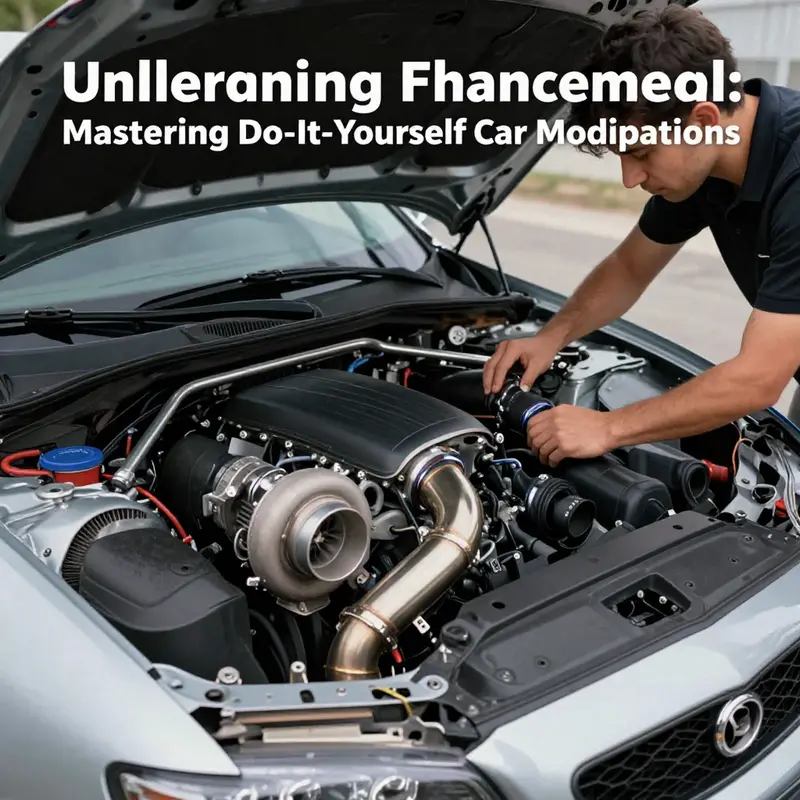

The Essential Toolbox: Mastering Tools, Techniques, and Safety for DIY Car Modifications

The thrill of transforming a machine you rely on into a more personal, capable version of itself begins with something surprisingly simple: a toolbox. For the hobbyist who wants to push a car beyond its stock boundaries, the right tools and a solid grasp of foundational techniques are not just conveniences; they are prerequisites for safety, reliability, and meaningful performance gains. DIY car modification is as much about disciplined method as it is about ambition. A well-chosen toolkit anchors your project in practicality, keeps you safe, and prevents small missteps from spiraling into costly repairs. It is easy to underestimate the value of preparation, yet in truth preparation determines both the scope of what you can attempt and how consistently you can finish a project that actually works when you turn the key again.

A basic toolkit forms the backbone of any modification plan. At minimum, a comprehensive set of wrenches—both open-end and socket—provides the versatility to reach fasteners in various angles and spaces. A dependable ratchet with a comfortable grip accelerates work in cramped or awkward spots, where hand-tightening would be impractical and torque-sensitive fasteners demand leverage. A reliable torque wrench matters more than most people realize. It preserves hardware integrity by applying exact clamping forces and helps avoid thread stripping, warped rotors, or misaligned assemblies that can haunt the vehicle long after you’ve finished the job. The oil you don’t spill and the seals you don’t scratch are often the quiet products of choosing the right torque values and torque wrenches that stay accurate under repeated use.

Beyond the basics, safety gear is not optional—it’s the first line of defense against the kinds of injuries that can abruptly derail a project. Gloves shield hands from sharp edges, hot components, and chemical residues; safety glasses keep debris and splashes from damaging vision; and ear protection becomes essential when you’re using impact tools or air-powered devices that amplify noise that can accumulate after hours of work. A clean, well-lit workspace reduces the risk of trips, slips, and lost fasteners. Part of the discipline of DIY modification is treating the shop as a controlled environment: a place where tools return to their designated spots, where a bin or magnetic tray holds screws and clips, and where you’ve mapped out a clear path from disassembly to reassembly. These habits matter just as much as the tools themselves.

Specialized equipment expands what you can tackle and how cleanly you can execute a modification. An impact driver, for example, makes short work of stubborn fasteners that refuse conventional removal methods. A sturdy floor jack paired with solid stands is indispensable for working safely underneath the car, whether you’re addressing brakes, suspension, or exhaust components. A battery charger is more than a convenience for a car kept idle in a workshop; it’s a diagnostic aid that helps you verify electrical health during troubleshooting. While the specialized gear might feel extraneous on a quick oil change, the deeper you go into performance upgrades, the more you’ll appreciate tools that minimize risk and maximize precision. The message is simple: select tools that are robust, suited to the tasks you most often perform, and capable of delivering consistent results across projects.

Understanding proper use is inseparable from possessing the tools themselves. The most important principle is that accuracy in assembly translates directly into reliability on the road. Applying the correct torque to engine bolts, axle nuts, brake components, and suspension mounts isn’t merely a mechanical nicety; it preserves the seal integrity, prevents bolt loosening under load, and protects against heat-related failures. Safely jacking up a vehicle, placing stands on level ground, and deferring undercarriage work to a stabilized, well-supported position prevents a single misstep from becoming a catastrophe. A responsible approach also means knowing when a task should be left to a professional, especially when modifications implicate critical safety systems or require specialized calibration equipment. The ethos of DIY car work should balance curiosity with caution, curiosity with respect for the vehicle’s design limits, and curiosity with the understanding that some systems demand measured, incremental changes rather than rapid, speculative alterations.

With the tools and safety groundwork in place, the body of techniques you employ begins to give structure to a DIY modification journey. A practical starting point is routine maintenance tasks that set a stable baseline: changing oil and filters, inspecting fluid levels, and ensuring the basic operating envelope of the engine remains pristine. An oil change, performed with care and the right oil specification, does more than refresh lubricants; it clarifies your understanding of the engine’s health. Replacing the air filters is a deceptively simple task, but it matters profoundly for engine efficiency and responsiveness. When air flows cleanly into the intake, the engine can breathe, and the throttle response becomes more immediate, a subtle but meaningful uptick for a vehicle that is otherwise stock.

As you gain confidence, you can progress to performance-oriented upgrades that require more nuance. Installing a performance exhaust system, for instance, hinges on mastering exhaust flow dynamics and ensuring proper sealing to prevent leaks that can prompt backpressure issues or exhaust gas exposure in the cabin. The braking system is another domain where precision matters: upgrading brake pads improves stopping performance, but correct installation and bedding-in procedures are essential to avoid rotor glazing or uneven wear that can sabotage performance gains. If you take a more data-driven path, you may engage in engine tuning using an OBD2 scanner. Reading trouble codes and incrementally adjusting engine parameters—within safe margins—can reveal how far you can push performance without compromising reliability or longevity. Each of these steps—oil changes, air filtration, exhaust, brakes, and engine tuning—illustrates a continuum where basic tasks cultivate a culture of careful observation, measurement, and incremental improvement.

As the project evolves, so does your understanding of how individual modifications interact. A cold air intake, for instance, is more than a tube and a filter. It requires careful routing to avoid unfiltered air entering the engine and a secure seal to maintain calibrated air-to-fuel ratios. A suspension upgrade further complicates the picture because it introduces dynamics that influence steering, cornering, and ride quality. Understanding alignment angles, spring rates, and dampening characteristics helps you predict how a change in one area will ripple through the chassis’ behavior. This is where the book on high-performance DIY mods becomes not just a how-to manual but a philosophy—an emphasis on method, measurement, and consistent documentation. Comprehensive guides in that tradition remind readers to approach each modification with a plan: identify the goal, map the steps, anticipate compatibility issues, and verify outcomes with a methodical testing process.

The knowledge you gather in the cockpit of a car, however, does not exist in a vacuum. To make sense of material choice, heat management, and endurance under repetitive loads, you can turn to forward-looking technical work in the field. For example, recent research into material selection explores how composition and mechanical properties influence durability, heat resistance, and performance under stress. This line of inquiry matters because a chassis upgrade or a high-performance component must withstand high temperatures, persistent vibration, and load cycles that challenge the integrity of the part. When you’re choosing between different aftermarket components—struts, brackets, or intake manifolds—the material story behind them helps explain why some options endure longer, respond with more consistency, or tolerate more aggressive operating conditions. Understanding these principles empowers a DIY enthusiast to select parts with confidence and to fabricate with an eye toward longevity rather than quick novelty.

It is also essential to anchor practical work in reputable standards and guidelines. The Society of Automotive Engineers (SAE International) offers peer-reviewed papers and guidelines that provide authoritative context for techniques, tolerances, and best practices. Access to those standards is invaluable when you are planning modifications that may affect safety, emissions, or reliability. They help you calibrate your own experiments against industry benchmarks rather than relying solely on anecdotal experience. For the enthusiast who keeps a notebook and treats each modification as a hypothesis tested against data, SAE resources become a trusted reference point that elevates the quality of home projects and reduces the risk of costly missteps.

The process of learning and doing in this space is iterative. Start with a clear objective—perhaps a modest horsepower improvement, a smoother ride, or enhanced braking confidence. Then assemble the appropriate tools, study the required techniques, and prepare your workspace for the task at hand. Document the steps, measurements, and results. If you encounter unexpected behavior, analyze the discrepancy between expected and observed outcomes, and adjust your approach accordingly. This practice—planning, executing, measuring, and reflecting—parallels scientific inquiry and professional engineering workflows. It also aligns with the ethos of the referenced DIY high-performance guide, which emphasizes practical, step-by-step execution while foregrounding safety and reliability. As you repeat this cycle, you will not only modify your car more effectively but also develop a deeper fluency with the systems that keep it safe and dependable on the road.

For readers who want a practical walkthrough of installation steps and a structured approach to integrating new components, a detailed primer exists at How to Install Modifications on a Car. This resource mirrors the spirit of the broader DIY movement: it treats tools not as ornaments but as instruments of learning, with every bolt, gasket, and connection becoming a data point in a long timeline of improvements. While the specifics of any single modification can vary from car to car, the underlying discipline remains constant: approach modifications with an accurate plan, a disciplined toolset, rigorous safety, and a readiness to adapt when measurements tell you a different story.

In sum, the journey of do-it-yourself car modification is a craft that grows from a solid toolkit and a mindset trained to value precision. Tools enable work; safety gear ensures you can continue the work; and the core techniques provide a ladder toward more ambitious projects. The broader literature, including accessible projects and high-performance guides, helps practitioners translate curiosity into consistent, reproducible outcomes. Alongside this practice, growing attention to material science and formal standards strengthens confidence that your modifications will endure beyond a few test runs on a quiet stretch of road. The result is not merely a more powerful or more stylish vehicle, but a deeper understanding of how a car behaves when its parts are tuned with care, tested with patience, and backed by a culture of safety, evidence, and responsible experimentation. Finally, keep in mind that the journey is as important as the destination: each completed task teaches you something new about the car’s physiology, the limits of your skills, and the creative potential of hands-on engineering.

External resource for further reading and guidelines: https://www.sae.org

DIY Power Plays: A Cohesive Guide to Do-It-Yourself Performance Upgrades

Power in your own hands is more than a performance metric; it is a disciplined practice that blends curiosity with engineering. Enthusiasts pursue higher horsepower not as an end in itself but as a means to sharpen the relationship between driver, car, and road. This pursuit rests on a careful balance: the desire for speed and responsiveness must be matched by a respect for engine physics, thermal limits, and the integrity of the vehicle’s fundamental systems. The journey into performance upgrades starts with honest assessment—what you want from the car, how you drive, and where your limits lie. It is easy to imagine dramatic gains from a single bolt-on or a bold tune, yet the real gains come when changes are designed to work together, not in isolation. A car is an integrated machine; every modification shifts the dynamics of air, fuel, ignition, and heat, and those shifts ripple through the chassis, brakes, tires, and cooling. A thoughtful approach recognizes this interconnectedness and rejects the fantasy of simple, one-size-fits-all miracles. It instead embraces a process of incremental improvements, careful testing, and measured learnings that build a reliable, repeatable path to more power without sacrificing safety or longevity.

At the heart of most DIY performance ambitions lies the Engine Control Unit, the electronic brain that orchestrates when and how efficiently each cylinder breathes. Recalibrating the ECU can unlock hidden capacity by adjusting fuel delivery, ignition timing, and, in turbocharged or supercharged setups, boost management. The essence of this tuning is subtle: the factory maps favor reliability, emissions, and durability. The DIY tuner learns to balance the air-fuel mixture, ignition advance, and volumetric efficiency so the engine can create more power without triggering knock or overheating. This is not a matter of cranking up numbers; it is a negotiation with the engine’s operating window. The broader lesson is that any tuning project should start with data. Collect baseline measurements of power, torque, air intake temperatures, and exhaust gas temperatures. Use this information as your compass. A reliable reader or data logger, paired with a conservative initial tune, can reveal how close you are to the edge and where the next cautious adjustment should land. The goal is not a single, loud figure but a sustainable improvement curve that the engine can repeat under typical driving conditions.

Beyond the ECU, the intake system stands as a practical and accessible frontier for noticeable performance gains. The idea is straightforward: reduce restrictions so the engine can breathe more freely. A high-flow intake system or a cold-air intake can shave seconds off throttle response and deliver a modest yet meaningful increase in horsepower and torque. The gains are not dramatic in most street setups, but the improvement is real and perceptible, especially as RPM climbs. The critical caveat with intake upgrades is heat. Air that courses through the intake can heat up before it reaches the combustion chamber, and heat-degraded air reduces performance. To minimize this, installers position the intake away from heat sources and route the intake path to stay as cool as possible until it reaches the throttle body. Additionally, it is essential to ensure that emissions systems, regional regulations, and inspection requirements allow intake changes. Case studies from the field consistently show that the combination of higher-flow air and precise fueling can yield smoother power delivery and quicker throttle response, even when measured on a dynamometer or observed on a track day. The beauty of this modification lies in its accessibility: many bolt-on kits are designed for simple installation with basic hand tools, and the changes are reversible should circumstances change.

Exhaust work follows a similar logic but speaks more directly to the engine’s ability to expel exhaust efficiently. A free-flowing exhaust reduces backpressure and frees up the engine to perform at higher RPMs with less effort. The effect on power can vary, but a well-mared exhaust system often translates into measurable gains and a more aggressive, confident exhaust note that reflects the improved flow. When choosing an exhaust path, a DIY builder typically considers options from lightweight cat-back systems to full replacement configurations that include headers and downpipes. The common thread is that the system should be engineered to minimize leaks, avoid harsh resonance, and maintain compatibility with the vehicle’s emissions and exhaust monitoring systems. It is worth noting that exhaust upgrades can involve welding or professional fitment, particularly for older or highly customized chassis. Even in bolt-on configurations, proper sealing, hanger alignment, and heat protection are essential to long-term reliability. The intersection of intake and exhaust is where the magic often becomes audible and tangible: a less restricted engine breathes easier, and the resulting throttle response can feel like a turbo boost without the complexity of forced induction.

For a significant leap in power, many enthusiasts consider forced induction, such as a turbocharger or supercharger. This path is the most dramatic, and it carries the most responsibility. Forced induction increases the amount of air entering the engine, and with more air comes the need for more fuel, robust cooling, and stronger lubrication. The complexity of this route cannot be understated. The installation involves intricate plumbing for air intake, intercooling, and oil delivery, as well as electrical work to control boost targets and safety interlocks. The heat produced under boost conditions imposes stringent demands on the cooling system. Without adequate cooling, a higher intake temperature reduces efficiency and invites detonation and component wear. Those who pursue this route should do so with a plan that includes upgraded fuel delivery, a reliable intercooler, and a mapped fuel strategy that matches the increased air supply. Even with a well-designed kit, the project benefits from a staged approach: begin with a conservative, calibrated tune and a modest boost, confirm the engine’s behavior under steady driving, and only then push toward higher limits after validating fuel stability and thermal margins. In the DIY context, many builders prefer pre-fabricated, professionally engineered kits that come with instructions and safety tolerances. While these are not the same as “plug-and-play” solutions, they reduce guesswork and enhance the likelihood of a balanced, reliable result. The overarching principle is to respect the engine’s stress boundaries and to approach power gains as a cumulative outcome of multiple, harmonized changes rather than a single, overpowering riff that destabilizes the entire system.

Ignition system upgrades offer another, more approachable lever to refine engine performance. Upgrading spark plugs to higher-quality, heat-resistant designs can sustain stronger combustion in the face of higher compression or boosted air, while performance ignition coils can deliver stronger, more consistent spark under load. The expected gains from ignition improvements are typically modest in well-maintained engines, but they can contribute to crisper throttle response, smoother idle, and a more stable air-fuel ratio when the engine operates at the edge of its performance envelope. The practical value of ignition enhancements grows when paired with improvements in fueling and air delivery, forming a triad of enhancements that support more aggressive tuning without relying on brute force alone. The key is compatibility: choosing ignition components that suit the engine’s architecture, timing characteristics, and service intervals helps preserve reliability and minimize maintenance surprises.

No performance journey is complete without acknowledging the system-wide implications of such upgrades. Upgrading intake, exhaust, and ignition in isolation can yield uneven results if fuel and cooling systems are not aligned. A more powerful engine requires a more capable fuel supply to keep air-fuel ratios in a resilient range under high-load conditions. It also demands a cooling strategy that can dissipate added heat without letting temperatures creep into unsafe zones. This means checking radiator capacity, ensuring effective airflow, and considering upgrades to oil cooling if the project pushes the engine into sustained high-RPM territory. It also means implementing a robust data-feedback loop: monitor the engine with a reliable OBD-II reader, log temperatures and knock events, and review the data after each round of testing. The aim is to validate gains with repeatable measurements and to confirm that the car remains predictable and safe on the street as well as on the track. The mindset is disciplined, not reckless; the goal is measurable improvement achieved through careful integration of multiple subsystems rather than a single, sensational tweak.

As with any modification, there are practical realities that shape what is feasible. Warranty implications can be significant, and in many markets emissions rules and inspection regimes can constrain or complicate certain upgrades. The responsible builder treats these realities as design constraints to be managed rather than obstacles to be ignored. A project plan that includes cost estimates, a parts-and-tools checklist, a realistic timeline, and a test plan helps keep expectations aligned with outcomes. It also invites a more methodical learning process, where each modification teaches the builder something about the car’s character, the limits of the chassis, and the interplay between power delivery and handling. The path to higher power is rarely a straight line; it is a winding route that rewards patience, data, and integrity. A well-executed DIY program recognizes the importance of safety margins, careful calibration, and the continuity between track testing and street reliability.

To maintain momentum without losing sight of the fundamentals, it helps to anchor the project in a few practical milestones. Start with a clear baseline of performance and a plan for incremental gains. Choose a modest, reversible modification first—such as an intake or a cat-back exhaust—and evaluate how the car feels and how it behaves under real-world conditions. Move to ECU tuning with careful, measured steps, validating each iteration with data and driver feedback. When you are ready to consider forced induction, enter that phase with a comprehensive understanding of supporting modifications, including fuel delivery, heat management, and drivetrain durability. The narrative here is not a litany of parts but a philosophy: build power progressively, ensure reliability at every step, and preserve the car’s balance with its steering, brakes, suspension, and tires. The thrill of a freshly tuned engine is best enjoyed when it remains controllable, predictable, and sane in everyday use.

For readers seeking a practical, beginner-friendly route that still respects the complexities of modern powertrains, a careful study of installation and tuning approach is invaluable. A concise, step-by-step guide to evaluating and implementing modifications—emphasizing safety checks, tool readiness, and diagnostic discipline—can serve as a bridge between curiosity and confident execution. With the right mindset, your DIY project becomes a structured exploration of how power, torque, and efficiency emerge from a tuned conversation between air, fuel, ignition, and cooling.

If you are curious about a practical, responsible path to modifications, you can explore a straightforward guide on how to install modifications on a car. This resource offers a grounded, process-driven approach that aligns with the principles outlined here. How to Install Modifications on a Car

In the end, the journey to increased power through do-it-yourself car modifications is as much about learning as it is about horsepower. It rewards preparation, restraint, and curiosity. It rewards those who measure twice and cut once, who understand that every gain in power comes with a corresponding obligation to maintain control, safety, and reliability. The road to performance is not a sprint but a careful ascent—one that asks you to balance ambition with prudence, to test with data rather than impulse, and to celebrate progress that endures long after the thrill of the first launch.

External reference for deeper technical grounding: https://www.hptuners.com/

Surface, Stance, and Self-Expression: A Deep Dive into Aesthetic Upgrades in DIY Car Mods

A car’s visual identity can be as telling as its heartbeat under the hood. Aesthetic upgrades in do-it-yourself car modifications are not merely about turning heads; they are about translating personal taste into a tangible, mobile canvas. For many enthusiasts, the thrill lies less in chasing performance numbers and more in shaping how a vehicle presents itself to the world. The DIY approach to aesthetics blends artistry with hands-on problem solving, inviting owners to design their own language of style while learning the limits and possibilities of their machines. In this realm, color, texture, form, and proportion become the vocabulary through which a driver communicates who they are, what they value, and how they intend to engage with the road.

Among the most visible and impactful aesthetic choices are paint and vinyl wraps. The old debate between enduring paint jobs and reversible finishes has evolved into a nuanced spectrum. Traditional paint remains a serviceable path for those seeking a permanent statement, with options that range from time-honored solid colors to rich metallics. Yet today’s matte, satin, gloss, and chrome effects expand the palette far beyond what was possible a decade ago. Color-shifting and pearlescent finishes, driven by light angles and subtle layering, offer a dynamic shimmer that responds to the sun, streetlights, and even the car’s own motion. On the other hand, vinyl wraps provide a cost-conscious, reversible alternative that preserves the factory finish beneath. Wraps enable bold graphics, complex patterns, or even entire body-color experiments without the commitment or potential resale concerns tied to a permanent paint job. For many DIY enthusiasts, wraps open the door to high-visibility experimentation—think bold graphics splashed across a front clip or a full-body design that can be peeled away with relative ease if tastes change.

The decision between paint and wrap hinges on several practical factors: how long you want the look to last, what level of maintenance you’re prepared to commit to, and how confident you are in executing or supervising the process. Paint demands a clean workspace, careful surface preparation, and a steady hand or a trusted professional for the finish. Wraps require precise measurement, careful masking, and a tolerance for air bubbles and edge sealing that can challenge first-time adapters but reward patient, methodical work with a nearly flawless appearance. Both paths share common ground in the importance of surface condition. A smooth, well-prepared base—free of rust, peeling stock finishes, or stubborn contaminants—ensures that either method yields durable results and a surface that ages gracefully. And while both routes can be pursued as a weekend project, the more ambitious undertakings often benefit from a measured plan and, when possible, input from someone who has done similar work before.

Beyond color and finish, the shape and silhouette of a car are equally ripe for aesthetic refinement. Body kits—comprising elements such as front lips, side skirts, rear diffusers, and aftermarket fenders—have become a defining language of visual personality. A well-chosen kit can sharpen a vehicle’s lines, add a purposeful stance, or subtly alter the aerodynamics to emphasize speed visually even if the performance gains are modest. The key with body kit modifications is cohesion. The new components should harmonize with the car’s original design language rather than clash with it. When done thoughtfully, a kit can convey a refined aggressiveness or a clean, modern simplicity that mirrors the owner’s taste. When done poorly, it can look patchworked or out of proportion, which undermines the very expression the modification aimed to achieve.

Custom grilles, hoods, and spoilers further sculpt a car’s character while reinforcing its identity. A distinctive grille can demarcate a face that feels more assertive or more serene, depending on the chosen geometry and texture. A vented or sculpted hood can echo performance cues and create dramatic shadows at idle or in motion, while a spoiler—subtle or conspicuous—can suggest athletic intent without any mechanical changes under the hood. The interplay between these elements matters as much as the individual parts themselves. Designers often consider how the front end interacts with headlamps, bumper lines, and the car’s overall stance to avoid visual dissonance and to maintain a sense of flow from one region to another.

Wheels and rims are perhaps the most immediate and transformative touchpoints for any aesthetic project. A new set of alloys or Forged rims can alter a vehicle’s stance, perceived weight, and grip on the road without a single engine bay modification. Offset, width, and diameter determine how aggressively the tire fills the wheel well and how the car sits at rest. The finish—machined, gloss black, bronze, or a vivid color—carries a personality that can either soften a harsh silhouette or amplify a sleek, angular profile. Careful attention to wheel fitment and tire sizing is important not just for appearance but for maintaining the intended ride characteristics and avoiding scrapes on turns or at parking limits. Maintenance considerations also factor in; lighter finishes can show brake dust quickly, while chromed surfaces may require periodic resealing to maintain their reflectivity and protection.

When enthusiasts conceive a complete visual transformation, they often adopt a layered approach: a new paint or wrap as the foundation, a body kit to define the silhouette, a grille or hood tweak to sharpen facial lines, and wheels to anchor the new stance. The result is a cohesive, personal statement that remains anchored in the underlying geometry of the car. Yet the process is rarely a simple one. It is a conversation between idea and execution, where measurements, tolerances, and aesthetic judgments must converge in a single, workable plan. Digital visualization tools can help bridge this gap before a single tool is touched. Platforms like Car Modifier Online give modifiers a way to experiment with different finishes, colors, and body elements in a virtual space. Visualizing a combination of wrap color with a front lip and aftermarket wheels can reveal clashes or harmonies that might not be obvious in the abstract or in a showroom brochure. This forward-looking step is invaluable for maintaining momentum and ensuring that the final result aligns with the dream while remaining faithful to the car’s character.

Aesthetics do more than make a vehicle look different. They can influence the way a driver carries themselves on the road and how others perceive the machine’s purpose. A car that looks thoughtful and well-executed signals care and attention to detail, which in turn can influence how it is treated by others on the street, in parking lots, and at events. For the owner, the process of selecting finishes, patterns, and structural accents is not just about making the car beautiful; it is about cultivating a personal narrative around the vehicle. That narrative often evolves with the owner’s changing tastes, driving experiences, and the evolving cultural landscape of car culture itself. And as the DIY community increasingly shares its projects, a well-documented aesthetic build can inspire others to imagine new directions for their own machines, creating a feedback loop of creativity and experimentation.

With aesthetic upgrades, there is always a practical layer to consider. Even when the emphasis is purely visual, modifications interact with the car’s insurance, resale value, and legal compliance. A visual upgrade can alter how a vehicle is perceived by insurers or how it is valued by a prospective buyer. Some tasteful enhancements retain a strong resale proposition because they emphasize quality craftsmanship and clean execution, while others may narrow the buyer pool if they appear overly polarizing or are not easily reversible. In the DIY space, balancing personal expression with broad appeal is a skill. It often means choosing finishes and components that are maintainable, reversible, or modular so that the car can be adapted again in the future without incurring a total loss of the original character.

To navigate these waters effectively, practical research and thoughtful planning are essential. An upfront assessment of the car’s existing condition, the owner’s budget, and the intended use can anchor decisions in reality. It is also prudent to consult resources that address the broader implications of modifications, such as how changes might affect resale value or insurance. A relevant discussion in this space highlights how different aesthetic choices translate into practical outcomes, guiding enthusiasts toward choices that are expressive yet responsible. The idea is not to chase trends blindly but to frame taste within a durable, well-executed plan that respects the vehicle’s integrity and the owner’s long-term goals. For readers who want to explore how modifications influence resale value, a concise overview of that topic can be found in dedicated content that links aesthetic choices to market perceptions. car modifications and resale value.

As the DIY community continues to map the evolving landscape of automotive aesthetics, it becomes clear that the strongest projects are those grounded in thoughtful preparation, precise execution, and a clear sense of purpose. The aesthetic journey is not about drawing attention for its own sake but about crafting a coherent, attractive representation of the driver’s identity. It is about turning a machine into a moving extension of the owner’s vision while maintaining respect for the vehicle’s original engineering. This balance—between self-expression and stewardship—defines the best of DIY car aesthetics. For builders who want to stay ahead of changing trends while keeping a lid on complexity, engaging with broad industry narratives and trends can be enlightening. A recent survey of modification trends suggests that drivers increasingly seek finishes and designs that are distinctive yet adaptable, allowing for easy refreshes as tastes shift and seasons change. External insights into broader modification trends can be found in current industry coverage, which highlights how the aesthetic conversation is evolving beyond simple color swaps toward integrated design language and modular components. See for example the latest trend discussions here: https://www.cars.com/articles/car-modification-trends-2025-12345/.

In the end, aesthetic upgrades in DIY car modifications are less about adopting a look and more about articulating a relationship with the vehicle. Each choice—the wrap or paint, the body kit, the grille, the wheels—carries with it a message about how the owner wants to engage with space, movement, and identity. When approached with care, even a bold, eye-catching look can coexist with respect for the car’s heritage and performance DNA. The result is not a superficial makeover but a meaningful collaboration between owner and machine, a testament to the DIY ethos: hands-on, thoughtful, and personal, turning a car into a true extension of the driver’s own voice on the road.

Safe Hands, Sound Roads: Navigating Safety in Do-It-Yourself Car Modifications

Working on a car can feel like a rite of passage for an enthusiast who wants to understand every creak, bolt, and wire in their ride. But the thrill of fiddling with performance, aesthetics, or reliability must be balanced with a boots-on-the-ground commitment to safety. In the world of do-it-yourself car modifications, safety isn’t an afterthought; it is the foundation that determines whether a mod delivers the hoped-for gains or creates new risks that jeopardize the driver, passengers, and other road users. As modifications move from cosmetic changes to performance-driven upgrades, the line between ingenuity and danger can blur quickly. A thoughtful, disciplined approach, anchored in established guidelines and sound judgment, turns DIY projects from impulsive tinkering into a responsible craft that improves driving experience without compromising stability, braking, or structural integrity.

Safety starts before a tool touches metal. The decision to modify a vehicle should begin with a clear assessment of purpose and consequences. Enthusiasts often pursue higher horsepower, sharper handling, or better fuel economy, but these goals come with trade-offs. Increasing engine output can stress driveline components, higher under-hood temperatures, and altered thermal cycles that shortchange longevity if not managed with compatible parts and tuning. Changing suspension geometry or spring rates can alter load transfer, ride height, and aerodynamics in ways that impact steering response and tire contact with the road. Even changes that seem purely cosmetic—from body panels to wheel fitment—can unintentionally affect braking balance, cornering behavior, or pedestrian safety visibility. The underlying principle is simple: every modification must be evaluated for its impact on the vehicle’s safety-critical systems, not merely its appeal or the novelty of the upgrade.

Regulatory compliance forms the first line of defense. Local rules govern emissions, noise, lighting, and safety-critical systems, and many jurisdictions require that modifications maintain, or at least not degrade, roadworthiness. Understanding the function of each component before altering it helps prevent unintended consequences. Engine tuning, exhaust alterations, suspension changes, and electrical work each carry unique regulatory and safety considerations. In practice, this means consulting official guidelines and manufacturer specifications to determine what is permissible and what requires certified modification or professional oversight. When in doubt, seek the guidance of qualified technicians who can interpret the legal framework and translate it into a practical plan that preserves compliance while achieving the owner’s objectives. The risk of noncompliance isn’t merely a legal concern; it also raises liability questions in the event of a crash or breakdown.

Part quality and compatibility matter as much as intent. Substandard or mismatched parts can fail under load, strain, or heat, sometimes in dramatic fashion. For example, a high-performance exhaust is not simply a pipe with a larger diameter; it changes backpressure and heat distribution, which can affect engine behavior if the rest of the system isn’t calibrated accordingly. Suspension components must match spring rates, dampers, and chassis geometry to maintain stable handling and adequate ground clearance. Electrical mods, too, demand parts that can tolerate the vehicle’s electrical environment, including battery voltage, charging system capacity, and ambient temperatures. In short, a single incompatible component can create a cascade of inefficiencies or mechanical failures. Sound judgment—paired with technical data from reputable sources—reduces the likelihood of selecting parts that undermine safety or reliability.

Guidance and knowledge act as a shield. The knowledge base around DIY auto work is broad and accessible, but not all sources are equally reliable. Manufacturer specifications and professional guidelines provide the baseline for safe modifications. Industry organizations, such as SAE International, publish peer-reviewed papers and guidelines that clarify the behavior of components under real-world conditions. These resources help distinguish what is technically feasible from what is prudent, and they illuminate the long-term implications of specific choices, including heat resilience, material fatigue, and tolerances. In addition to industry literature, established safety agencies offer practical scope on what is permissible and what requires professional handling. The National Highway Traffic Safety Administration (NHTSA) provides detailed guidelines on vehicle modifications, highlighting that changes affecting critical safety systems—like airbags, seat belts, steering, or braking—should be approached with caution and ideally executed by certified professionals. Relying on authoritative sources reduces the risk of ad hoc decisions that escalate danger. Readers can consult official guidelines and technical resources to ground their projects in proven safety practices, rather than solely chasing performance metrics.

Every practical project begins with a plan that respects personal limits and environmental realities. Personal protective equipment is a non-negotiable starting point. Gloves protect hands from sharp edges, heat, and pinching hazards; safety glasses shield eyes from flying debris and fluids; and appropriate clothing—long sleeves, sturdy pants, closed-toe shoes—minimizes skin exposure to cuts, burns, or chemical splashes. Even with the best PPE, the environment matters. A clean, well-lit workspace with proper ventilation reduces the likelihood of slips, trips, or inhalation of fumes. Good shop hygiene becomes part of the safety protocol: tools returned to their racks, chemical containers sealed, and waste disposed of correctly. When electrical work is involved, the battery must be disconnected to prevent short circuits or electric shock, and the power source should be isolated from any metal surfaces that could become unintended conductors. A fire extinguisher, ideally rated for electrical or automotive fires, should be within easy reach, and a plan for emergency communication and escape should be part of the setup. The goal is not to avoid risk altogether but to manage it systematically.

The real engine of safety is a disciplined workflow. Vehicle work should proceed in stages, with careful testing and verification at each step. Before touching any system, a precise assessment of load paths, safety margins, and potential failure modes is essential. This means checking torque specs, fastener materials, and thread engagement, and not assuming that all aftermarket components can be torqued to factory guidelines by memory. It also means validating cooling capacity when performance parts are introduced. The balance between heat generation and heat dissipation becomes critical, especially in high-performance builds where temperatures can spike and stress adjacent subsystems. After installation, components must be inspected regularly. Early signs of wear—unusual vibrations, noise, creeping misalignment, or changes in pedal feel—can indicate impending issues that, if ignored, may progress into dangerous failures. A simple, recurring inspection routine—before each road test, after the first few miles, and then at scheduled maintenance intervals—helps catch problems before they escalate.

Testing and road readiness deserve special emphasis. A measured testing approach reduces risk and builds confidence in a new setup. Start with controlled environments: a flat, empty lot or a private, closed course offers a safe space to assess handling, braking response, steering feel, and throttle response. Observing how the car behaves under low- and mid-range loads provides early feedback about how modifications alter dynamics. It is essential to re-establish baseline measurements where possible. If handling has been altered, a track or a certified test facility might be the appropriate venue for more rigorous evaluation, under the oversight of qualified professionals. Incremental gains are wiser than dramatic, all-at-once changes. Modifications should be phased, with performance tests after each phase to confirm that the anticipated benefits are realized without compromising control or reliability. In the public realm, visibility and signaling must remain compliant. Changes to lighting, trim, or exterior components should be reviewed for nocturnal visibility and the ability of other road users to anticipate the vehicle’s behavior.

The social dimension of DIY safety is often undervalued, yet it matters as much as the mechanical work itself. A community of peers can provide practical insights, share lessons learned, and help flag issues that may not be apparent to an individual. However, this resource comes with a caveat: anecdotes should not substitute for verified standards. Relying on personal experience alone can embed unsafe practices. When in doubt, compare notes against manufacturer guidelines, SAE standards, or NHTSA recommendations. If a forum discussion seems to advocate a radical approach without addressing safety implications, take a step back and seek independent verification. The right balance is to use online communities as a sounding board while maintaining a core practice of cross-checking information with official standards and, when needed, consulting a licensed technician or engineer.

This chapter’s guidance extends beyond the individual project into ongoing stewardship of a modified vehicle. Regular inspections should become an ongoing habit, not a one-time rite of passage. The changes you make are part of a system: the engine, the exhaust, the suspension, and the braking hardware operate together in a delicate equilibrium. Any alteration can ripple through this system, altering how it responds to road conditions, weather, and wear. The safer path is a comprehensive plan that includes documentation of every modification, a schedule for maintenance that anticipates wear patterns, and a willingness to revert or revise changes if performance or safety concerns arise. A vehicle is a dynamic instrument; it requires continued care, not just one successful installation.

Ultimately, the philosophy of safety in DIY car work is about empowering enthusiasts to pursue improvements without surrendering responsibility. It is about recognizing that the road is a shared environment, where performance gains must be earned with respect for the vehicle’s limits and the realities of fatigue, heat, and human error. The responsible DIYer blends curiosity with caution: a willingness to learn from credible sources, a commitment to using proper tools and PPE, and a readiness to pause a project if the data or the situation suggests risk. This mindset does not dampen the spirit of experimentation; it channels it into a disciplined craft that yields dependable gains and sustains the long-term health of the vehicle. For readers who want a practical starting point, consider exploring a structured installation guide that emphasizes safety steps and proper sequencing. You can read about one such approach here: how-to-install-modifications-car.

As DIY car modification culture continues to evolve, the core principle remains unchanged: safety builds trust—trust in your ability to work with complex systems, trust in the reliability of your modifications, and trust in the road that carries you forward. By weaving regulatory awareness, part compatibility, authoritative guidance, PPE, environment, and a measured testing protocol into every project, enthusiasts can transform the garage into a place of legitimate innovation rather than a risk-laden workshop. The journey toward safer, smarter modifications is continuous, demanding ongoing education, deliberate practice, and an honest assessment of personal and environmental limits. In that space, the garage becomes not just a place to modify a car, but a workshop for responsible, thoughtful engineering that respects the road as much as ambition wants to push beyond it. For readers seeking broader context on safety standards and guidelines, trusted external resources offer essential grounding and up-to-date information: https://www.nhtsa.gov/vehicle-modifications.

Final thoughts

Embarking on the journey of DIY car modifications is much more than mere automotive enhancement; it is an exploration of creativity and technical skill. By equipping yourself with the essential tools and techniques discussed, along with understanding performance upgrades and aesthetic modifications, you can foster a rewarding connection with your vehicle. However, the excitement of modding should never overshadow safety. Adhering to safety protocols ensures not only your personal safety but also the longevity of your modifications. Ultimately, DIY car modifications present an opportunity to merge passion, performance, and personalization into one exhilarating package.