For car enthusiasts, the thrill of personalization often leads to exciting modifications that enhance performance, aesthetics, or comfort. Yet, with every modification comes the risk of voiding your vehicle’s warranty—a reality that many hobbyist modifiers, professional tuners, and restoration enthusiasts must navigate. Understanding the nuances of how various alterations impact warranty coverage is essential for anyone making changes to their vehicle. This article will delve into four critical areas: engine modifications, exhaust system changes, suspension upgrades, and the use of non-approved parts and fluids. Each chapter will explore how these aspects can influence warranty validity, helping enthusiasts make informed decisions as they modify their rides.

Throttle, Tuning, and Warranty: How Engine Tweaks Can Make or Break Coverage

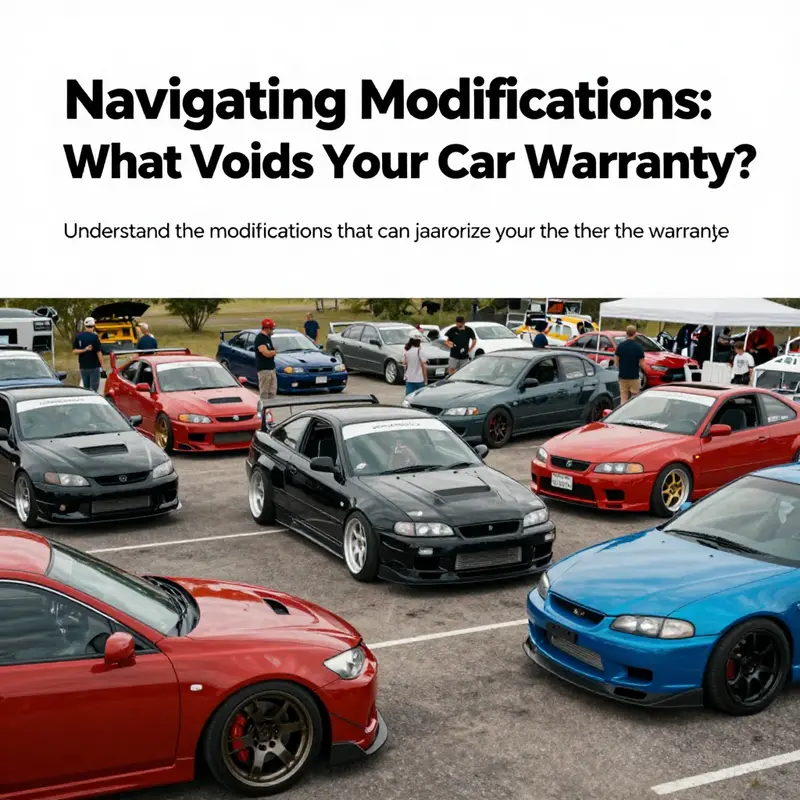

Engine work lives at the heart of most car enthusiasts. The thrill of a sharper throttle response, quicker acceleration, or a sportier note from the exhaust is seductive. Yet the same impulses that push a driver to seek performance gains can also tug at the boundaries of a manufacturer’s warranty. This chapter looks at how engine modifications affect coverage, why some changes trigger warranty denial, and how to navigate the gray areas with care. It takes a practical, real world view, recognizing that warranties exist not just to cover a single component but to ensure the vehicle operates within the safety, emissions, and reliability expectations set by the maker. Reading the warranty terms is essential, but so is understanding how different modification pathways intersect with engine management, calibration, and long term reliability. The goal is not to dampen curiosity but to illuminate a path that preserves protection while pursuing legitimate performance goals.

When we talk about engine modifications, the most scrutinized area is the engine control unit and the software that governs it. The ECU is the central hub that coordinates fuel delivery, ignition timing, boost pressure, and various safety controls. A change here can ripple through almost every subsystem. Manufacturers design calibration maps to balance performance with emissions compliance, fuel economy targets, and reliability margins. Even seemingly small changes in fueling or timing can alter temperatures, stresses, and wear patterns in components that were never intended to be stressed beyond a certain point. Because of this, unauthorized ECU modifications are viewed with heightened suspicion by warranty providers.

There is a meaningful distinction between officially sanctioned upgrades and independent, uncertified tinkering. Some manufacturers and their authorized dealers offer ECU upgrades that are explicitly tested and approved. These programs are designed to preserve compatibility with the rest of the vehicle’s systems, including emissions controls, onboard diagnostics, and safety features. When performed within an official upgrade track, these changes can often be covered under the existing warranty, or at least clearly delineated so that coverage for unrelated failures remains intact. The key here is provenance: a known, approved upgrade with manufacturer documentation tends to align with the warranty framework rather than against it.

By contrast, unauthorised or aftermarket software modifications can void the warranty on the components that were altered or influenced. The logic is straightforward from the manufacturer’s perspective: altering the engine management system can change how the engine responds to inputs, potentially increasing stress, altering heat profiles, or changing emissions behavior. If a failure occurs, and the root cause can be traced to the modified calibration, the warranty claim for the affected parts is vulnerable. Even if the problem arises from a separate subsystem, some manufacturers reserve the right to deny coverage if the repair would not have happened but for the modification. In other words, a failure might be technically independent, but the link to the modified control strategy makes coverage uncertain.

The regulatory backdrop adds another dimension to the discussion. In the United States, for instance, the Magnuson Moss Warranty Act prohibits a manufacturer from voiding a warranty simply because a consumer used an aftermarket part. The law is nuanced, however. If the modification directly caused the failure, the manufacturer can deny coverage for the related repair. If a vehicle exhibits a failure that could be due to either the modification or an unrelated defect, many dealerships will investigate the root cause before deciding on warranty eligibility. The practical implication for owners is clear: keep the modification and the vehicle history transparent, and ensure that the modification is not likely to be blamed for a separate issue.

For some readers, the most rational path through this landscape is to pursue modifications that stay within clearly defined boundaries. A certified, dealer-backed ECU upgrade is one such boundary, a reversible and well documented way to improve performance without destabilizing the vehicle’s safety or emissions framework. Reversible, plug and play modules that do not permanently alter the ECU calibration can also offer a compromise. These devices provide an additional layer of performance or regulation compliance without permanently rewriting the engine control logic. They can be removed, restoring the vehicle to its stock state, which helps preserve warranty coverage if a claim arises. Yet even these solutions require careful vetting and documentation to ensure they do not inadvertently trigger unexpected fault codes or electrical anomalies that could complicate a warranty assessment.

This careful approach is not merely theoretical. Real-world scenarios illuminate how engineering choices intersect with coverage. A driver who seeks more peak horsepower through forced induction or aggressive cam timing must consider not just the immediate performance gains but the longer arc of reliability and repair costs. Forced induction increases manifold pressures within the intake and combustion chambers. It can elevate exhaust gas temperatures, stress turbochargers or superchargers, and push cooling systems beyond their baseline design margins. If a cooling system or an oil supply line fails, a dealer or manufacturer will examine whether the failure occurred because of the modification or because of a latent defect in the stock design. If the latter, coverage may still apply to the defective component, but the modification-related damage could be excluded or limited. In many cases, the outcome hinges on documentation, test results, and the explicit terms of the warranty agreement.

Another important axis is the relationship between modifications and emissions controls. Modern engines rely on a finely tuned balance of sensors, catalysts, and exhaust aftertreatment to meet regulatory requirements. Alterations to intake, exhaust, or fueling can cause the engine to operate outside the approved envelope. When that happens, the vehicle may emit different levels of pollutants, triggering compliance concerns. If a failure arises that is connected to an emissions system, the manufacturer may argue that the modification voids coverage for that emissions-related component. In practice, this means that even a modification with no direct mechanical impact on a given engine part can create a scenario in which the warranty becomes uncertain if emissions-related issues surface later.

The body of guidance around engine modifications often emphasizes the importance of keeping thorough records. Documentation that demonstrates the modification was performed by an authorized technician, the specific hardware or software used, the calibration version, and the date of service can be critical in a warranty dispute. In some cases, the service provider can supply a formal statement that confirms compatibility with the vehicle model, the absence of adverse effects on safety systems, and the continued integrity of critical components. Stored maintenance and repair histories, receipts, and diagnostic reports become pieces of a larger puzzle. When a fault report arrives at the dealership or the manufacturer, these documents can clarify whether the modification contributed to the problem or if the issue stands on its own.

For many drivers, the friction between performance ambition and warranty protection is not about a single part but about the total philosophy of modification. The most durable approach is to view modification as a series of decisions with escalating risk. Start with education about how the engine management system works. Learn what constitutes an approved upgrade path and what constitutes an unapproved modification. Then map out a plan that emphasizes reversible or officially sanctioned options. If the upgrade is contractually supported by the manufacturer, maintain clear records of the authorization and the scope of the coverage. If not, consider alternative routes that deliver the desired driving experience without compromising warranty protection.

This is where the concept of risk assessment becomes useful. Before undertaking any significant engine modification, a driver can perform a self assessment that weighs the potential performance gains against the likelihood of warranty denial, out-of-pocket repair costs, and the long-term reliability of the vehicle. A practical framework includes identifying the failure modes most likely to be affected by the modification and evaluating how those failure modes would be treated under warranty. It also involves setting a threshold for acceptable risk. If the risk of losing coverage for a major subsystem is too high, the path of modification may be reconsidered or refined toward options with greater warranty compatibility.

A subtle but meaningful element of this discussion is the way conversations with technicians and sales staff are conducted. Open, proactive communication with the vehicle manufacturer or an authorized dealer can prevent confusion later. When a modification is proposed, request a formal written explanation of how the upgrade interacts with the vehicle’s warranty and which components remain protected. This is not merely a legal safeguard; it is a practical safeguard. It helps ensure that the engineering intent aligns with the warranty language and that both parties share an understanding of what is and is not covered in the event of a failure. The process reduces the chance that a repair will be disputed simply because a claim was not well supported by the underlying facts.

To make this topic more concrete for readers who want a navigable reference, there is a useful resource that offers a broader view of how car modifications sit within warranty considerations. It frames the discussion in a practical, user-friendly way and provides a balanced perspective on when modifications can be pursued without sacrificing protection. See the car modifications guide for a structured overview of common paths and their warranty implications. car modifications guide.

At the same time, it is important to maintain perspective about limits. Not every engine modification is inherently incompatible with warranty coverage. Certain, clearly documented upgrades that are tested and approved by the manufacturer can preserve coverage for related systems. The central insight is that relationship and traceability matter. If a modification is shown to be the root cause of a failure, coverage for the affected components may be denied. If there is no clear link between the modification and a given problem, many warranty decisions will focus on whether the problem could reasonably be expected to arise from factory conditions. In practice, this means the safer path is to pursue upgrades that come with explicit manufacturer endorsement and a well-documented support chain.

Beyond the moral and legal implications, there is a practical economic calculus. Warranty coverage has real cost implications. If coverage is denied for an engine component because of an unauthorized modification, the owner faces repair costs that can be substantial. Even when a repaired part is not directly linked to the modification, the perception of risk can influence the total cost of ownership through higher maintenance outlays or a more limited resale market. The decision to modify, then, becomes a blend of desired performance, demonstrated reliability, and the value placed on preserving warranty protection. It is not a binary choice but a strategic one.

Finally, the chapter circles back to the central question posed by many readers: what is the best way to pursue engine performance without jeopardizing warranty protection? The answer is nuanced and highly dependent on the vehicle, the modification, and the language of the warranty contract. The safest, most dependable route is to work within manufacturer sanctioned programs and to document every step of the process. In parallel, maintain a planning mindset that focuses on reversible or non invasive enhancements whenever possible. This approach does not diminish the joy of driving or the satisfaction of engineering achievement; it simply aligns it with a framework designed to protect the vehicle and the owner over the long arc of ownership.

For those who want to extend their understanding beyond the scope of this chapter, there is value in exploring the broader context of car modifications and insurance, durability, and long term value. The materials cover a range of scenarios that illuminate how modifications can affect multiple facets of ownership, sometimes in unexpected ways.

External resource: https://www.toyota.com/warranty

The Emissions Edge: How Exhaust Modifications Can Void Your Car Warranty

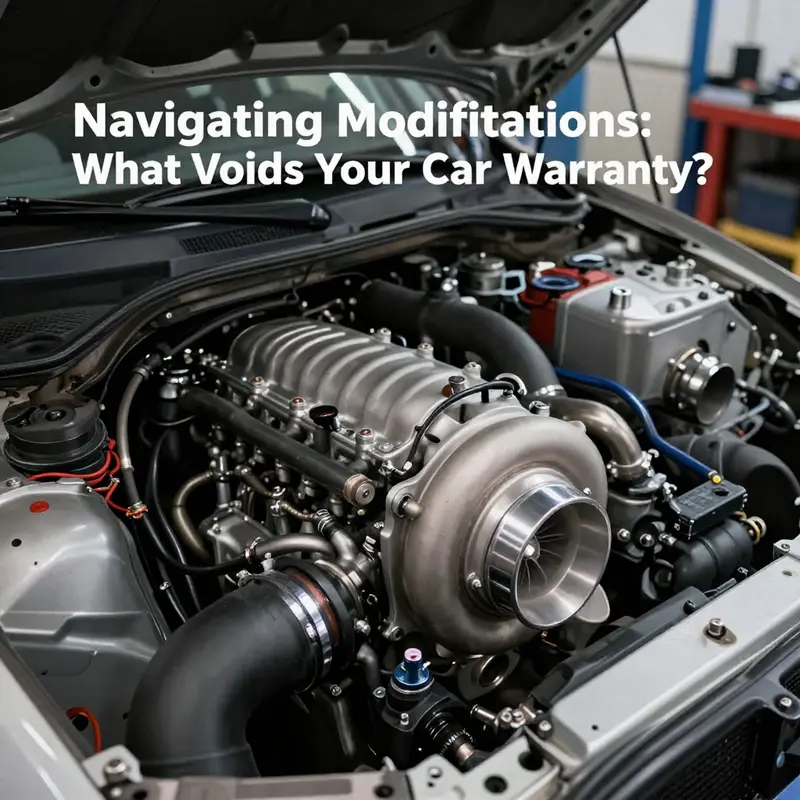

Exhaust system changes sit at a delicate crossroads of performance, legality, and warranty protection. They promise louder notes, a perceived gain in power, and a certain allure for enthusiasts. Yet the moment a modification steps outside the boundaries of the vehicle’s design and the law’s emissions requirements, the risk shifts from mere optics to real consequences for warranty coverage. The core tension comes from how exhaust changes interact with the vehicle’s emissions controls. A system that keeps a vehicle compliant with emissions standards is less likely to trigger warranty denials, while a modification that bypasses, disables, or otherwise disturbs those controls can invite scrutiny from manufacturers and service centers alike. This is not simply about whether a part is aftermarket or whether a dealer will approve the change; it is about whether the modification preserves the integrity of the emissions system and whether it creates a plausible link between the modification and the failure that is being claimed under warranty.

At the heart of this issue lies the legal framework that governs emissions in many jurisdictions, especially in the United States. The Environmental Protection Agency, under the Clean Air Act, prohibits tampering with emission control systems. An exhaust modification that removes, bypasses, or in any way disables catalytic converters or other mandated components is not merely a performance tweak; it is a potential violation of federal law. If that violation leads to increased emissions beyond legal limits, a manufacturer may deny warranty coverage for engine or drivetrain issues tied to the modification. The law recognizes that emissions control systems are essential to public health and environmental protection, and tampering with them carries consequences that extend into warranty considerations. This is not a barrier meant to stifle legitimate performance enhancements, but a framework intended to prevent harmful and noncompliant changes from becoming the default standard.

The most important principle to keep in mind is that the Magnuson-Moss Warranty Act provides broad protection to consumers: manufacturers cannot void a warranty simply because an aftermarket part exists. They cannot automatically claim that a modification voids coverage for unrelated defects. However, this protection is not absolute. If the modification itself directly causes the failure that is being claimed, the warranty can be denied for the affected components. And crucially, if the modification affects emissions compliance, the warranty protection may not apply to emissions-related problems. In short, there is a distinction between a modification that is passive, noninvasive, and does not interfere with the emissions system, and one that actively changes how the exhaust system governs pollutants and sensor readings. In those latter cases, the lines between performance, legality, and warranty become significantly more nuanced.

Practical implications emerge quickly in routine service visits. An aftermarket exhaust that replaces the stock system with a freer flowing design may be aesthetically appealing and even technically suitable for some engines. Yet that setup can trigger diagnostic trouble codes when oxygen sensors detect altered exhaust gas composition or when the downstream sensors read values inconsistent with the engine’s own control logic. A stored fault code can illuminate a check engine light, and the technician may inspect the system to determine whether the modification directly caused the problem or whether it is merely an ancillary contributor. If engine damage occurs and the manufacturer concludes that the altered exhaust caused abnormal heat, altered backpressure, or sensor misreadings that led to the damage, warranty coverage may be denied for those related components. The outcome hinges on the causal connection the manufacturer can demonstrate between the modification and the defect.

This is where the value of compliant modifications becomes clear. A functioning exhaust upgrade that bears EPA or CARB certification, and that is installed with proper documentation, stands a much better chance of preserving warranty coverage for components that fail within the normal wear and tear of operation. Certification acts as a bridge between performance goals and compliance obligations. It signals that the part was designed to meet emissions standards and that it has undergone testing to verify that it does not unduly upset sensor readings or emissions output when integrated with the vehicle’s control systems. Even with certified parts, a manufacturer can still challenge coverage if the failure shown in the claim can be traced to a condition caused by the modification, such as a miscalibrated tune that created a new fault path. The broader lesson is that the safest route lies in compatibility, documentation, and professional installation rather than unilateral experimentation.

A practical question many drivers face concerns whether simply replacing the exhaust with a different style—one that preserves the catalytic converter, maintains proper oxygen sensor placement, and keeps the overall emissions system intact—could still trigger warranty issues. The answer depends on the specifics: does the new system maintain the same emissions performance within legal limits? Does it alter backpressure in a way that can be tied to a particular failure? Is there a reasonable link to a defect that the warranty is meant to cover, or is the link tenuous and speculative? In most cases, a well-engineered, certifiably compliant exhaust that preserves the emissions control architecture reduces the likelihood of warranty denial for unrelated failures. Yet even in such scenarios, an insistently nonstandard installation that rewires sensors or bypasses safety features can still complicate warranty coverage if something goes wrong.

From the standpoint of the vehicle owner, there is a compelling incentive to approach exhaust modifications with a blend of caution and due diligence. Start with the owner’s manual and the manufacturer’s warranty terms. The manual often contains specific guidance on what is allowed and what would be considered a modification that could affect coverage. Several manufacturers and dealers emphasize that any aftermarket parts should be chosen with appropriate certifications and installed by qualified professionals who understand the vehicle’s diagnostic architecture. When speaking with a service advisor or a warranty administrator, it is prudent to articulate the intent of the modification, provide documentation that shows compliance with emissions standards, and request confirmation in writing about how coverage may be affected. A proactive, documented approach can help prevent disputes if a claim later arises for a problem unrelated to the exhaust modification itself.

To further emphasize the path toward compliance, consider the broader ecosystem surrounding exhaust changes. The Clean Air Act compliance framework is not a mere abstract principle; it translates into tangible requirements for aftermarket products. The EPA emphasizes that aftermarket exhaust components should not be designed to bypass or defeat emissions controls. The objective is to ensure that performance enhancements do not come at the expense of public health by allowing pollutants to exceed permissible limits. Consequently, choosing exhaust systems that are designed to retain the integrity of catalytic converters, oxygen sensors, and catalyst heating strategies is not merely a matter of legal compliance; it is a practical approach to safeguarding warranty coverage. In many jurisdictions, compliant parts come with documentation that can be presented to a dealer if an emissions-related concern arises.

From a consumer guidance perspective, there is value in understanding that not all exhaust modifications are equal in their warranty implications. A subtle distinction exists between components that are strictly cosmetic or that do not alter emissions behavior and those that influence the engine’s exhaust flow characteristics. Cosmetic changes, such as decorative exhaust tips or nonfunctional cosmetic hardware, typically do not affect warranty coverage unless they cause physical damage or interfere with the system’s mechanical integrity. In contrast, performance-oriented changes that modify backpressure, exhaust gas temperature, or sensor readings carry a far higher risk of creating a direct or indirect link to a defect that could be claimed under warranty. The practical implication for drivers is clear: preserve the functional emissions pathway whenever you pursue exhaust upgrades.

Seeking a balanced approach requires consulting reputable resources and staying informed about the evolving regulatory landscape. For readers who want a concise frame of reference on the legality and warranty considerations surrounding car modifications, a dedicated overview of legal car modifications can be a helpful companion piece. See the page on legal car modifications for a grounded discussion about how to navigate these questions without stepping outside the boundaries of compliance. Legal Car Modifications. This resource can help you assess what is permissible and how to document modifications in a way that supports both performance goals and warranty protection. While the specifics of each vehicle and jurisdiction differ, the underlying principle remains universal: the safest path is to align modifications with the vehicle’s design intent and the law’s emissions standards, then pursue documentation and professional installation to preserve warranty coverage for unrelated failures.

Ultimately, the analysis of exhaust modifications and warranty is a narrative about responsibility as much as it is about performance. Enthusiasts who chase loudness or additional horsepower must also contend with the legal and contractual implications of their choices. The owner who plans ahead, who selects certified parts, who documents the installation, and who refrains from bypassing emissions controls, is not simply reducing risk to the warranty; they are exercising informed stewardship over a complex machine designed to meet both engineering and environmental standards. The warranty, after all, is not a guaranteed shield against wear and tear; it is a contract that reflects the manufacturer’s expectations about how the vehicle should operate within prescribed limits. When modifications respect those limits, warranty coverage can remain intact for the issues that arise from normal use. When modifications push beyond those limits, the risk shifts from a purely mechanical question to a regulatory and contractual one—a shift that many drivers would rather avoid by choosing pathways that honor both performance and protection.

External resources and ongoing scholarship on emissions and vehicle modifications reinforce this stance. The broader legal and regulatory context is as important as any individual technician’s assessment. For those who want to explore the formal environmental and regulatory landscape further, the Environmental Protection Agency offers a detailed gateway into vehicle emissions testing and related compliance questions. The official resource at the EPA provides authoritative information on how emission control systems are evaluated and what constitutes tampering under federal law. It is wise to consult that material when considering any exhaust modification that could interact with emissions controls or trigger emissions-related fault conditions. https://www.epa.gov/vehicle-emissions-testing

In sum, exhaust system changes occupy a pivotal position in the larger conversation about what modifications will void or preserve a car warranty. They are not inherently disqualifying; they become problematic when they undermine emissions control systems, violate environmental standards, or cause damage that can be plausibly traced to the modification. A thoughtful, documented, and compliant approach to exhaust upgrades protects the integrity of the warranty while still offering avenues to enhance performance. By prioritizing certified components, professional installation, and alignment with emissions laws, owners can enjoy the benefits of an upgraded exhaust without stepping into the risk zone that threatens warranty coverage. And for those who want a succinct point of reference about the legal dimensions of car modifications, the linked legal car modifications page provides a practical starting place to navigate these questions before you commit to a change.

null

null

The Fine Print of Fitment: How Non-Approved Parts and Fluids Can Void Your Car Warranty

Warranties are promises tempered by the realities of engineering and maintenance. They cover manufacturing defects and failures that arise under normal use, but they are not unlimited indemnities for every aftermarket impulse. The tension between customization and coverage centers on one simple truth: many warranties hinge on the use of parts and fluids that meet the original specifications. When a non-approved part or an unapproved fluid enters the picture, a warranty claim can be denied or limited. To understand what you risk when you veer from the manufacturer’s prescribed components, it helps to see how this plays out in practical terms and how the rules translate across ownership of a modified vehicle.

In practice, a failure linked to a non-OEM part or non-approved fluid is a potential ground for denial. The logic is safety, performance, and reliability. If a part fails and the manufacturer did not design or specify it, there is a plausible argument that the failure could be due to the unapproved part rather than a defect in the vehicle’s original design. This is not a blanket prohibition on all aftermarket parts, but it is a warning signal: the more a modification diverges from the approved spec, the more scrutiny your warranty claim will attract. The principle is that vehicles are complex systems with tightly coupled subsystems; a change in one area can ripple into others, affecting safety, emissions, and durability.

The line between coverage and exclusion becomes especially salient when a claim involves multiple components. If a failure involves a component that relies on an approved part or fluid, but the root cause traces to a non-approved element elsewhere in the system, some manufacturers will still look for a direct causal link. They may deny the claim for the non-approved part while offering coverage for unrelated failures, or deny coverage for the entire vehicle if the non-approved component is deemed a material contributor. The risk is not merely theoretical; in practice, the decision can hinge on the specificity of the warranty language, the documentation available, and the manufacturer’s interpretation of “unapproved modification.” This is where the guidance in warranty documents becomes crucial. The documents typically spell out that modifications should not compromise safety, emissions, or conformity with design specifications. A modification that appears cosmetic or benign may still have consequences if it alters a subsystem that interacts with the engine, the transmission, or the vehicle’s safety systems.

The Magnuson-Moss Warranty Act provides consumer protection but works in concert with the contract-based warranty language. When a modification is clearly implicated in the failure, the warranty is more likely to be denied. The practical takeaway is straightforward: keep records that demonstrate compatibility, approvals, and proper installation; obtain written authorization from the manufacturer or a dealer before proceeding; and maintain clear documentation to support coverage if needed.

Across industries, the logic persists: approvals exist for a reason. They ensure that pieces fit together to maintain safety, reliability, and traceability. The broader point is not that all non-approved parts are dangerous, but that the absence of official approval introduces ambiguity into fault analysis when things go wrong. This ambiguity is what warranty terms seek to minimize.

What can you do to protect yourself? Use parts and fluids certified or approved by the manufacturer when possible. If you consider an aftermarket option, seek explicit written confirmation of compatibility and warranty implications before installation. Keep receipts, specification sheets, and certifications that demonstrate the part meets required standards. If a modification requires a different service interval or diagnostic approach, document those differences. A well-documented, manufacturer-approved plan helps separate the problem from the modification in dispute.

Equally important is an honest assessment of risk and reward. Some modifications align with manufacturer guidance when approved or performed by authorized service personnel; others may be routine and lower the likelihood of warranty denial. Weigh benefits against potential costs to coverage and resale value. The decision to modify should consider the documentation, installation quality, and potential impact on coverage. The same approach applies to other domains such as electronics or aviation, where approvals exist to maintain safety and traceability. By approaching modifications with planning, verification, and documentation, you preserve coverage and reduce ambiguity when issues arise.

For readers seeking practical guidance, consult the warranty documentation or the manufacturer directly. Warranty terms vary by country, model, and language. If you are in a jurisdiction with different consumer protection laws or dealing with imports, interpretation can shift. The reliable approach is to ground decisions in the exact language and verify ambiguous points with the company before committing to a modification. For those who want to explore how such decisions intersect with insurance, some insurers require disclosure of modifications and can adjust terms accordingly.

Beyond vehicles, the guiding principle remains: use approved components and fluids whenever possible, document decisions, and seek clarity before altering the system. The goal is not to restrict creativity but to preserve the vehicle’s design integrity, reliability, and service predictability. If something goes wrong after a modification, the repair path should follow the compatibility framework set by the manufacturer and your contemporaneous documentation.

In sum, non-approved parts and fluids do not automatically erase warranty protection, but they raise the threshold for coverage. The defining criteria are causation and documentation. If the modification causes the failure, coverage may be denied or limited; if the failure is unrelated, coverage for the rest of the vehicle may still apply with proper documentation. The safest approach is to rely on manufacturer-approved components, secure written approvals for any deviation, and maintain meticulous records of installation and maintenance. This helps preserve reliability and minimizes disputes.

External resources: What Modifications Affect Car Insurance and the broader principle: Liquid damage and warranty information.

Final thoughts

Modifying your vehicle can lead to exhilarating enhancements, but it’s crucial to remain aware of the potential warranty implications these changes may bring. As explored in the chapters, engine modifications, exhaust system updates, suspension enhancements, and the use of non-approved parts and fluids each carry specific risks that can jeopardize your warranty coverage. To ensure your modifications are enjoyable and within your warranty’s safety net, always consult with your vehicle’s warranty documentation and stay informed about the manufacturer’s policies. Remember, when in doubt, consult a professional or your vehicle’s manufacturer before making significant modifications.