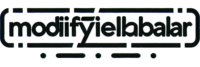

Car modification is not just a hobby in Japan; it’s a vibrant culture steeped in tradition and innovation. With a legal framework supporting car enthusiasts, Japan allows a variety of modifications as long as they comply with strict regulations. This article dives deep into the essential aspects of car modification legality in Japan, exploring topics such as the legal framework, safety regulations, environmental standards, the critical shaken inspection, and the cultural perception surrounding vehicle modifications. Each chapter aims to build a comprehensive understanding of how enthusiasts, professional tuners, and global fans can creatively engage with vehicular customization while respecting Japan’s regulatory landscape.

Engineered Freedom on Japanese Roads: Navigating the Legal Framework for Car Modification

Japan is famous among car enthusiasts for its blend of precision engineering, disciplined tuning, and a regulatory backbone that keeps streets safe while allowing meaningful customization. The idea that modification is possible on public roads in Japan rests not on lax freedoms but on a carefully designed legal framework. This framework sits at the intersection of safety, emissions, and vehicle integrity, and it operates through a clear set of standards managed by the Ministry of Land, Infrastructure, Transport and Tourism (MLIT) and enforced through the annual shaken inspection. The result is a system that can accommodate bold personalization—whether for performance, aesthetics, or practicality—so long as builds stay within defined boundaries and are properly documented and approved through the right channels. For readers who want a concise sense of practical rights and responsibilities, a good entry point is to explore how legal car modifications are approached in Japan, such as through resources that translate regulatory nuance into working guidelines. Legal car modifications offers a bridge from theory to practice, highlighting the core pathways that keep a modified vehicle road-legal without stifling ingenuity.

At the heart of the system lie two foundational statutes: the Road Transport Vehicle Act and the Road Traffic Law. These laws set out the baseline expectations for any car that leaves the factory and again when it returns to the road after changes. The guiding principle is simple yet exacting: modifications must not obstruct visibility or compromise steering, must preserve the functionality of mirrors and lighting, and must keep the vehicle within safety and emissions standards. This trio of constraints is what makes the process navigable rather than punitive. The safety standards, known in Japanese as Ankō Kijun, function as a national benchmark. They specify, among other things, how components and assemblies must perform under typical driving conditions and how modifications must impact overall vehicle behavior. The Ankō Kijun approach means that a performance upgrade or styling change is not automatically exempt from scrutiny; it must be reconciled with a shared standard that ensures safe operation for the driver, passengers, and other road users.

Within this regulatory fabric, modifications are organized into four broad categories, each with its own procedural posture. First, there are Non-Reporting Modifications, or Designated Parts. These are pre-approved components that have earned an official certification label proving they meet safety and emission standards. They include items such as certain exhaust systems, suspension kits, wheels, tires, and interior accessories. If a vehicle uses only designated parts and stays within weight and dimensional limits, no change in registration is required. This pathway is designed for broad customization with a minimum procedural burden, allowing enthusiasts to alter aesthetics or tune handling without triggering a full bureaucratic process. The crucial caveat is certification: each designated part must carry that official label, confirming it adheres to national safety and environmental criteria.

The second pathway, Reporting Modifications, covers changes that exceed the scope of designated parts but do not require a complete re-engineering of the vehicle. When owners alter engine type, significantly modify the body shape, or change maximum payload or passenger capacity, they must submit a notification to the Land Transportation Bureau. There is no need for prior approval, but the modified vehicle must still pass a technical inspection to verify compliance with safety standards. This route reflects a pragmatic balance: it acknowledges meaningful, documentable changes while preserving the state’s gatekeeping power before the car can again be driven on public roads.

The third category concerns Reconstructed Vehicles, or Kōzōsha. This designation applies to vehicles that have undergone major structural or mechanical modifications—engine swaps, chassis alterations, or other substantial transformations. Reconstructed vehicles must undergo full re-registration and a comprehensive technical review. Approval is granted only if the vehicle demonstrates ongoing compliance with safety, emissions, and dimensional regulations. This is the most rigorous pathway because it treats the final product as a new or heavily altered design, demanding thorough verification across multiple systems to ensure no hidden risks exist.

Finally, there is the category of Unapproved Modifications. If any change renders a vehicle non-compliant with safety standards—even in a minor way—the car becomes a non-compliant vehicle and cannot be registered or legally driven on public roads. The examples here are instructive: illegal exhaust systems that bypass catalytic converters, headlights or taillights altered to colors outside the permitted spectrum, excessively wide wheels that intrude into the fender or reduce clearance to less than the allowed tolerance, or tampering with identifiers such as the vehicle’s make, model, engine number, or chassis number. This framework emphasizes a clear boundary: safety and standardization trump unchecked customization, and non-compliant vehicles are excluded from legal operation.

The practical upshot of these categories is that enthusiasts have legitimate, well-defined routes to pursue their goals. The Designated Parts approach enables a wide spectrum of customization with relative ease, provided each part is certified and the vehicle remains within specified weight and dimensional limits. When a broader change is desired—such as a significant engine swap or a change to the vehicle’s fundamental architecture—the Reporting Modifications pathway offers a formal mechanism to document, inspect, and verify the new configuration. If the changes amount to a reconstructive transformation, the Kōzōsha route ensures that every safety, emission, and dimensional parameter is reassessed through a full re-registration and technical review. It is this tiered architecture that converts potential legal risk into a structured pathway for innovation. The system is not a blanket permission; it is a disciplined framework designed to preserve road safety and environmental integrity while honoring the country’s deep tuning culture.

Within this structure, several concrete restrictions shape how modifications unfold in practice. For example, while Japan permits high-horsepower builds—engine swaps or powerful enhancements can be pursued—the modifications must not violate emission or noise standards. In fact, a critical constraint is that changes must not push a vehicle beyond the Safety Standards or Ankō Kijun thresholds. A modern, high-performance engine can be installed, but the resulting emissions must stay within the law’s limits, and any noise produced must comply with regulatory noise limits. The color palette is likewise regulated: a vehicle may display up to three body colors, but it cannot be painted in colors associated with public service vehicles, such as taxi yellow or emergency red. Interior modifications are generally permissible so long as safety is not compromised; removing seats or altering structural integrity is not allowed, but cosmetic changes or upgrade-oriented interior enhancements that do not affect critical safety features or crash performance are commonly accepted.

An additional nuance concerns temporary installations. If a designated part is installed non-permanently—bolted on rather than welded, for example—the modification may not trigger a registration change. This nuance provides a practical pathway for evaluation, trial fitment, or short-term experiment without forcing a formal re-registration every time a part is tested. Yet the overarching requirement remains that any modification must survive the shaken and the inspection process. Failure to comply can lead to rejection during the annual inspection, fines, impoundment, or even criminal liability if the modification contributes to an accident. In short, the law does not punish creativity; it holds accountability for how that creativity translates into on-road safety.

The Clover R34 example underscores how serious, well-documented work can thrive within this framework. The Clover tuning collective, active from 1999 to 2005, showed that a balanced approach—focusing on responsiveness, handling, and real-world testing—could yield highly refined builds that still pass official scrutiny. Their emphasis on collaboration with the regulatory process, careful documentation, and a chassis-appropriate approach illustrates the kind of discipline that defines legal customization in Japan. The Clover R34 story is not merely a legend; it is a blueprint for how to achieve precision tuning without compromising compliance. It demonstrates that a car can be transformed through meticulous engineering while remaining a lawful, road-legal vehicle when the work aligns with the regulatory architecture.

For those navigating this landscape, the path begins with understanding the categories and the need to document and certify parts. It also means engaging with the right institutions and ensuring that each alteration is traceable to a compliant design standard. The culture surrounding Japanese car modification is thus not one of avoidance of rules but of disciplined integration—where passion meets procedure. This approach has not only sustained a thriving tuning culture but also fostered a climate in which high-performance customization can coexist with reliable road safety and environmental stewardship. Enthusiasts who respect the boundaries and work through official channels often build not just faster cars, but cars that embody a rigorous standard of quality and responsibility.

As readers move through the broader article, this chapter should serve as a reminder that modification in Japan is not a sinkhole of bureaucracy but a structured playground. It invites a deeper appreciation of how a country with an intense automotive heritage negotiates public safety and private passion. The path from an idea in a garage to a legally registered, shaker-approved vehicle is paved with certifications, inspections, and a clear understanding of what can be altered and how. The chapter’s core takeaway is that legality in Japanese car modification rests on a well-defined framework that rewards meticulous engineering, transparent documentation, and compliance with safety and environmental norms. It is this balance—between freedom to customize and obligation to maintain safety—that defines the true Japanese approach to modern tuning.

External resource: https://www.mlit.go.jp/road/vehicle/index.html

Speed, Safety, and the Rulebook: How Japan’s Safety Regulations Shape Legal Car Modification

In Japan, the romance of car modification unfolds not as a free-for-all but as a careful negotiation with a set of strict, codified rules. Enthusiasts who want to tailor performance, aesthetics, or functionality to their tastes must weave their plans through a legal fabric designed to protect everyone on the road. This isn’t about stifling creativity; it’s about ensuring that every meaningful alteration keeps the vehicle predictable, safe, and compliant with emissions expectations. When seen through this lens, modification becomes a disciplined practice rather than a reckless hobby, a distinction that explains why Japan has fostered both a vibrant tuning culture and an enduring commitment to road safety.

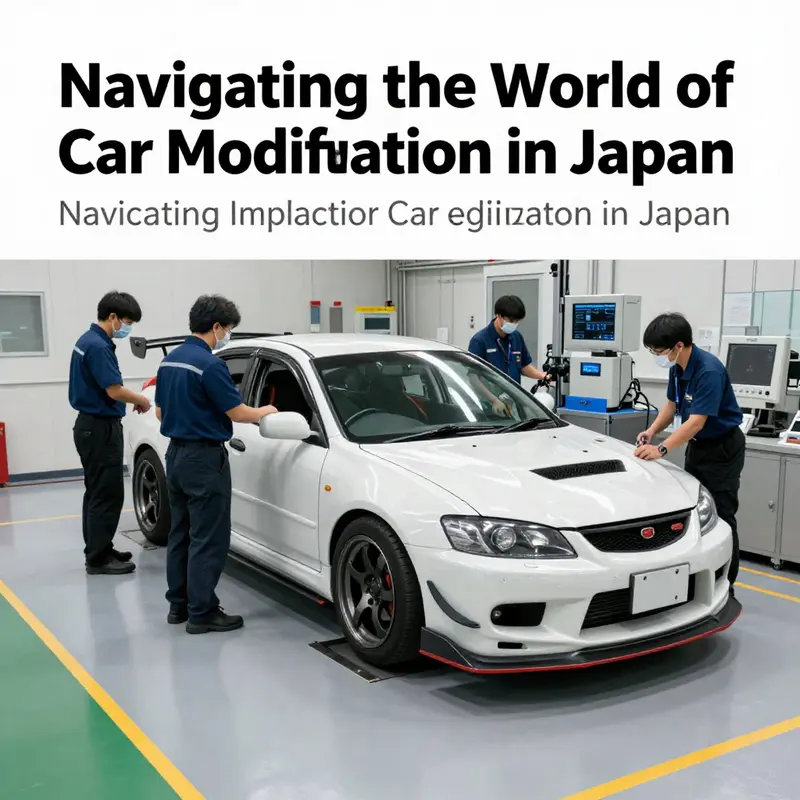

The backbone of this framework is the Road Transport Vehicle Act and the accompanying safety standards. These laws set the baseline for how a car can be altered and what kinds of changes must be documented and approved before they can be passed through the annual inspection cycle. The annual inspection, known as shaken, is not a mere formality. It is a recurring, comprehensive check that the vehicle remains roadworthy, especially after modifications. Modifications that fail to meet approved standards or for which there is no official certification can cause a vehicle to be deemed unfit for the road, effectively suspending its legal use until compliance is achieved. In practical terms, this means that every ambitious build must be conceived with a clear path to official validation, not just a bold idea envisioned in a garage.

The regulatory emphasis on safety is both broad and precise. At its core, the system guards four critical domains that matter most when a car leaves the factory floor and enters daily traffic: structural safety, power and emissions, lighting and signals, and tires and wheels. Each domain is a checkpoint that ties a design decision to a real-world safety outcome. For structural safety, the rules scrutinize any modification that could alter the chassis, body integrity, suspension geometry, or braking performance in ways that might degrade stability. An example is a modification that lowers the ride height without preserving the correct suspension geometry or braking balance. In a panic stop or an emergency swerve, the altered dynamics could produce unpredictable behavior. The regulations demand that any such change be backed by documented tests and an approved plan, ensuring the car remains predictable under stress, not just on a closed course but on typical city streets and highways as well.

Power and emissions sit at the intersection of performance aspirations and environmental responsibilities. Here the governing principle is clear: increases in engine displacement, horsepower, or torque must be officially certified and compatible with emissions standards. Replacing an engine with a larger unit, or removing a catalytic converter, triggers strict scrutiny and is treated as a serious violation. The rationale is straightforward. A higher-output engine paired with an exhaust system that bypasses pollution controls can dramatically alter the vehicle’s emissions profile, undermining air-quality goals and potentially compromising downstream safety systems that depend on exhaust characteristics. The process to achieve lawful power upgrades thus becomes a formal one, often requiring calibration reports, emissions data, and sometimes additional approvals that align the modification with environmental and safety mandates.

Lighting and signals may seem like peripheral concerns to the performance-minded, but in Japan they are essential safety features. The rules prohibit non-standard lighting configurations and prohibit excessively bright or non-compliant colored lights on the vehicle. Front-end red or blue lighting, which could mimic emergency vehicles or mislead other drivers, is not permitted. The same goes for alterations that would interfere with the visibility of standard lighting systems or the signaling function of lamps and indicators. The intent is not to curb style but to maintain predictable signaling cues for other road users. Even small deviations can trigger rejection at inspection, underscoring the idea that a mod should preserve or clearly enhance the car’s communicative reliability on the road.

Tires and wheels, while seemingly cosmetic, are treated with equal seriousness. Modifications to wheel size or offset are not unrestricted. The new wheels must conform to the dimensions, width, and offset specified by the manufacturer, and tire specifications must follow the manufacturer’s recommendations. This ensures that the tire contact patch, steering response, and suspension travel align with the vehicle’s design intent. The message is simple: when you modify wheels or tires, you must stay within the geometric and performance envelope that the car’s engineering established. It’s a reminder that even aesthetic choices can ripple into handling and safety, and so they demand careful validation.

Behind the scenes, Japan has built a structured ecosystem to support this careful approach. Accredited repair shops, designated by the government, serve as the nodes through which modifications are validated and inspections are conducted. This network is not merely gatekeeping; it is a knowledge base. Trained technicians understand how to document changes, verify compatibility with safety standards, and prepare the vehicle for shaken testing. By centralizing expertise, the system reduces the risk of unsafe or noncompliant work slipping through the cracks. It also means that the path to legal modification is navigable when vehicles are planned with proper guidance from qualified professionals.

This regulatory architecture has shaped the ethos of Japan’s tuning culture in meaningful ways. Enthusiasts know that lawful customization is not about bending rules so far that consequences become uncertain; it is about a collaborative process where ideas are tested against standards and documented for official approval. A landmark example, discussed within tuning communities in more general terms, is a highly refined modification project that emphasized balance, responsiveness, and track-focused handling rather than sheer power. The builders approached their work with real-world testing, careful calibration, and a readiness to document every change to pass official scrutiny. Their success is often cited as proof that high-level customization can coexist with strict compliance, and that a vehicle can be both a unique statement and a roadworthy machine when designed within the legal framework.

For anyone curious about how these principles translate into everyday practice, the starting point is a clear understanding of what the law requires and how the inspection process operates. Documentation becomes a crucial artifact. Every component change—whether to the chassis, suspension, engine management, exhaust system, lighting, or wheels—needs a traceable plan, supporting data, and, where necessary, official certification. In parallel, owners should seek out accredited shops for modifications and for the eventual inspection steps. In this way, the creative impulse to tailor a car remains intact, even as the vehicle stays anchored to safety and environmental standards.

The broader implication of this framework is not that Japan is closed off to modification, but that modification is an exercise in disciplined innovation. The public road system serves as the ultimate proving ground, and the shaken process functions as a safety net that ensures every build remains predictable and road-ready. When the public sees a modified car, what they are really witnessing is a collaboration between an inventive owner, a qualified technician, and a set of regulatory guardrails designed to keep speed and style from outpacing safety. This synergy explains why Japan remains a reference point for enthusiasts around the world who seek to balance personal expression with responsible engineering.

For readers seeking practical guidance that aligns with these principles, there is a resource that distills the core idea of permissible modification into accessible guidance. It presents the concept of legal car modifications in a concise, user-friendly format and outlines how to approach documentation, official approvals, and inspections in a way that keeps projects moving forward without compromising safety. This resource can serve as a gateway for newcomers who want to understand the terrain before engaging with technicians or inspection bodies. Legal car modifications.

Ultimately, the Japanese model demonstrates that a thriving modification scene can coexist with rigorous safety oversight. The key is a transparent process that places safety outcomes at the heart of every decision. Vehicle owners who plan thoughtfully, work with accredited professionals, and document their changes comprehensively are well positioned to enjoy both the uniqueness of their builds and the assurance of roadworthiness. As the chapter that follows will explore the practical steps in navigating the modification pathway—from conceptual design to shaken certification—the reader will see how the system translates high-level safety principles into an achievable, legally compliant reality. The official framework sits behind every successful project, reminding us that in the pursuit of speed and style, safety and legality must lead the way. For official guidance and regulatory details, external resources from the government provide foundational context and updates as standards evolve: https://www.mlit.go.jp/

Environmental Standards for Modified Vehicles in Japan: Balancing Customization with Clean Air Commitments

When people ask whether car modification is legal in Japan, the answer hinges on a careful balance between personal expression on the road and the nation’s hard environmental and safety standards. Modifications are not simply a matter of taste or power; they trigger a regulatory assessment designed to keep air quality and road safety at the forefront. In practice, modification is permitted when changes stay within the framework set by national agencies and when each alteration can pass a formal certification process. This framework is not a barrier to creativity, but a structured pathway that links customization to accountability. The result is a tuning culture that values precision, documented approval, and ongoing compliance as much as it values speed or stance at a car meet or on a mountain pass.

Central to this framework is the Ministry of Land, Infrastructure, Transport and Tourism, or MLIT, whose environmental standards govern how modifications affect emissions and fuel efficiency. The rules are explicit: any engine work, exhaust alterations, or other changes that could influence pollutants must be tested and certified before the vehicle can be legally driven on public roads. This is not a one-off check. It represents a continuing obligation, because Japan’s environmental policies are designed to adapt to evolving air quality targets and new technologies. In practice, this means a modified vehicle must be re-evaluated under the latest Environmental Standards for Motor Vehicles whenever significant changes are made. The emphasis is on ensuring that a vehicle, even after customization, continues to meet the country’s strict limits on pollutants such as nitrogen oxides and particulate matter.

The certification process itself is precise and technical. When a car’s exhaust system is altered or an engine is tuned for performance, the modification must undergo reconstruction and verification under what is described as the Japanese Certification Test, or JCT. The aim of the JCT is not to penalize ingenuity but to confirm that the modification does not raise emissions beyond permitted thresholds. If a modification causes a vehicle to fail the JCT, it is deemed non-compliant, which means it cannot be registered for road use until it meets the required standards. In other words, legal modification is a two-step dance: design and documentation in the workshop, followed by formal testing in a controlled environment and finally a validated registration update. The onus rests on the owner to hold onto the documentation proving that aftermarket parts have been approved under Japan’s Technical Standards for Road Vehicles, or JIS, which explicitly tie aftermarket components to environmental requirements.

This interplay between design, testing, and documentation reflects a broader national ambition: to reduce greenhouse gas emissions and improve air quality in crowded urban centers. It is not an abstract goal but a daily reality in cities like Tokyo and Osaka, where the density of traffic and the scale of daily journeys magnify the impact of exhaust emissions. The environmental standard system acts as a throttle, ensuring that the impulse to personalize a vehicle does not undermine public health or climate commitments. For owners and enthusiasts, this means that planning any modification requires a clear view of how the change will be tested, what paperwork will be needed, and how the modification will be reflected in official vehicle registrations. The process rewards meticulous record-keeping and anticipates the end-to-end lifecycle of a modified car.

The practical implications of these standards become especially clear when considering the annual shaken, Japan’s mandatory inspection. A modified car must not only survive the initial certification but also continue to pass the shaken every year. The shaken tests a vehicle’s safety and emissions performance under real-world conditions, which means a modification that seemed compliant at the outset could become problematic if it drifts out of specification over time. Thus, the culture of modification in Japan is deeply anchored in ongoing responsibility. Enthusiasts learn early that the joy of tweaking a car is inseparable from the discipline of maintaining it within the legal boundaries. This mindset helps explain why many workshops that cater to tuning also emphasize compliance as a core service, offering guidance on what changes are feasible within the law and how to document them properly for the JCT and shaken.

A telling aspect of this environment is the emphasis on balance rather than sheer power. In the long arc of Japan’s tuning history, the most respected modifications tend to optimize handling, responsiveness, and efficiency rather than simply chasing horsepower curves. The focus on balance aligns with broader environmental goals and with the technical realities of modern engines, where tuning for performance without compromising emissions or fuel economy is a sophisticated and increasingly valuable capability. This philosophy resonates with many enthusiasts who seek driving experiences that are precise, predictable, and safe on public roads. The regulatory framework rewards such a philosophy by keeping the road legal status intact while allowing a wide range of creative expression.

Throughout this landscape, documentation remains the shared language of legality. Owners must be prepared to show that components introduced through aftermarket channels have undergone appropriate evaluation and approval. The documentation trail might include certificates, test results, component specifications, and official confirmations of compliance with JIS standards. A robust chain of custody for parts and a clear narrative of changes help inspectors see that every modification has been accounted for and remains within environmental limits. When this clarity exists, the affection for a car’s uniqueness can flourish inside the lines drawn by law, enabling drivers to enjoy both the thrill of customization and the peace of regulatory certainty.

Within the cultural memory of Japan’s modding scene, public road legality is often illustrated through stories of careful, well-documented builds that nevertheless deliver compelling road manners. A well-known tuning collective from the earlier era exemplified how measured, track-informed changes could translate into road performance without compromising compliance. The emphasis on tested balance, road-legal exhaust developments, and transparent documentation helped set a benchmark for responsible customization. Though the specifics of that story lie in shared community lore, the underlying lesson remains constant: legal modification is a discipline as much as an art, combining engineering judgment with respect for environmental and safety standards. This is the model that continues to guide new generations of builders who want their creations to endure long after the first test drive.

For anyone contemplating modifications, several practical principles flow from the environmental framework. First, begin with a clear plan that identifies how every change could influence emissions and fuel efficiency. Second, engage with a reputable workshop that understands both performance goals and regulatory constraints. Third, secure the necessary documentation early, including any approvals related to JIS and the JCT. Fourth, anticipate the shaken inspection by validating emissions performance through appropriate testing and ensuring that any after-market parts can be supported by official certifications. By integrating these steps into the modification process, enthusiasts can chase the thrill of customization while honoring the country’s environmental and safety commitments. This approach turns a potentially risky pursuit into a sustainable, shared pursuit that benefits drivers and communities alike.

For readers seeking a practical pathway through this regulatory landscape, a concise guide exists that outlines the steps and considerations involved in car modifications. Learnings from the guide emphasize how to navigate the documentation and testing requirements, how to time changes with inspection cycles, and how to align your build with environmental standards. See the Car Modifications Guide for a focused overview of this process. Additionally, those who want to deepen their understanding of the broader regulatory context can consult the official MLIT guidelines on environmental standards for road vehicles, which provide the authoritative basis for all certification and testing decisions. The links below offer avenues for further exploration, including the wider body of laws and procedures that shape what is permissible on Japan’s roads.

External resource: MLIT official guidelines. https://www.mlit.go.jp/

Shaken as Gatekeeper: How Japan Manages Legal Car Modifications While Keeping Roads Safe

In Japan, the culture of experimentation and customization that many car enthusiasts cherish exists hand in hand with a rigorous, highly specific regulatory framework. The key to this balance lies not in a blanket ban on modification but in a structured process that ensures each tweak, upgrade, or aesthetic change is measured against safety, environmental standards, and roadworthiness. The Shaken inspection, formally known as 车検 in Japanese, is the central mechanism that translates this philosophy into practice. It is a mandatory, biennial checkpoint that every owner must navigate, and for modified cars it becomes the critical test of whether a dream build can truly ride the public streets. This system preserves the ability to personalize and push performance while guarding against risks that would threaten other road users and the broader traffic ecosystem.\n\nFrom the outset, the Japanese approach treats modification as a spectrum rather than a binary permit. Some modifications are straightforward and commonly accepted, such as upgrading brakes for better stopping power or swapping wheels for safety-compliant variants that fit within the vehicle’s structural and clearance requirements. Other changes, like engine upgrades or suspension alterations, demand closer scrutiny. The Shaken inspection extends beyond checking the generic, factory baseline; it requires a careful evaluation of every alteration to ensure it does not undermine crash safety, emissions controls, or the vehicle’s fundamental integrity. In effect, Shaken operates as both gatekeeper and validator: it filters out changes that would compromise public safety and, at the same time, validates those that enhance performance or aesthetics without crossing legal boundaries.\n\nThe practical implication for a car owner is clear, though not always simple: modifications are permitted so long as they are documented, approved through appropriate channels, and capable of passing the Shaken test in its current form. This means plans are not simply about what looks or feels best in a garage. They require alignment with a regulatory framework that emphasizes measurable criteria—safety, emissions, and structural soundness. A well-planned build, therefore, does not exist in a vacuum. It is mapped against a checklist that is both technical and legal in nature, ensuring that every bolt, mounting point, and aerodynamic feature can be inspected and validated on inspection day.\n\nA core aspect of this framework is the role of specialized shops and documentation. Enforcing compliance is easier when the work is performed by certified mechanics who understand Japanese standards and know how to present the vehicle for Shaken with the appropriate paperwork. The process often involves documenting the exact parts used, their compatibility with the vehicle, and any modifications to the engine, suspension, or exhaust system. When modifications are made with this level of transparency, the likelihood of passing Shaken increases substantially. Conversely, undocumented or poorly executed changes can trigger a failure, with consequences ranging from costly reworks to the temporary loss of road legality. In this sense, Shaken rewards meticulous planning and professional execution, reinforcing a culture where personalization and safety grow together rather than at odds.\n\nIn the broader narrative of Japanese tuning culture, there is room for high-skill, track-oriented work. A cited historical example in the tuning community illustrates how deep knowledge of balance, control, and responsiveness can coexist with strict regulation. While the specifics of that project are widely discussed in enthusiast circles, what matters for policy observers and hobbyists alike is the underlying principle: modifications must be part of a disciplined, test-informed process. The takeaway is not merely that clever engineering can pass inspection, but that the system encourages a thoughtful approach to upgrades. This approach emphasizes how the car behaves at the limit, how a vehicle communicates its dynamics to the driver, and how those dynamics remain aligned with safety standards when tested under Shaken’s scrutiny.\n\nThe Shaken framework thus acts as both a gatekeeper and a validator. It ensures that even highly customized builds respect safety thresholds and emission limits, while still offering room for personal expression and performance enhancement. This dual function is essential in a country where road safety, environmental stewardship, and personal automotive culture are integrated rather than treated as separate concerns. It also frames a practical reality for owners and builders: you plan, you document, and you test. If the test is passed, the modified vehicle can continue to be driven legally on public roads; if not, adjustments must be made, often with the help of qualified professionals who understand how to realign a vehicle with the country’s standards.\n\nFor readers navigating this landscape, it helps to anchor the concept in accessible terms. The process begins with a clear understanding of what adjustments are permissible within the law and how to prepare for Shaken. A good first step is to engage with reputable modification specialists who are familiar with the inspection criteria and can guide choices that are both performance-driven and compliant. It is not simply about finding parts that perform better; it is about identifying parts that fit within the vehicle’s architecture and can be authenticated during inspection. The emphasis on documentation and formal approval is not a bureaucratic burden; it is a roadmap that helps enthusiasts translate aspirations into road-legal reality.\n\nThe legal framework also recognizes the value of open information and community learning. Enthusiasts often share experiences, not as tips to bypass rules, but as guidance on how to align a build with Shaken’s expectations. This community knowledge helps bridge the gap between outside-the-box ambition and the practical constraints of road legality. In Japan, the dialogue between builders, inspectors, and regulators is ongoing, contributing to a landscape where safety is not a constraint on creativity but a platform for responsible innovation. If you are curious about the broader ecosystem of lawful car modifications, consider reading about the concept of Legal car modifications, which outlines the principles that guide compliant customization. Legal car modifications.\n\nThe Shaken framework, while exacting, does not exist to suppress individuality. It exists to ensure that each modification is compatible with the vehicle’s structural design, does not create unanticipated hazards, and does not push emissions beyond permitted thresholds. This is why the test often involves hands-on checks of bracket welds, suspension mounting points, exhaust routing, and even the alignment of lighting and visibility systems. It is not merely a ceremonial formality; it is a practical exercise in risk management. A well-prepared build can demonstrate to inspectors that it was conceived and executed with the same care that went into designing the car in its factory form, only now with enhanced performance or personalized features that remain within the bounds of safety and law.\n\nImportantly, the Shaken system interacts with other regulatory elements, including vehicle registration, parts certification, and standards for noise and emissions. Modifications that affect these dimensions must follow appropriate processes, including certified parts and, in some cases, additional approvals. The interlocking nature of these requirements means that a modification plan is best conceived as a holistic project rather than a series of isolated upgrades. In Japan, where national safety and environmental policies strive for a high level of domestic reliability, such coherence is not only sensible but expected. The result is a tuning culture that is sophisticated, technically informed, and deeply respectful of the rule of law.\n\nThe practical implications for owners extend beyond the inspection day. A modified car that passes Shaken can remain legally drivable for the duration of its inspection cycle, typically two years for most vehicles. That period becomes a window of opportunity to enjoy the vehicle’s enhanced performance while continuing to monitor compliance with evolving standards and regulations. Owners who plan to keep modifications in the long term often adopt a maintenance mindset that includes periodic reassessment of parts and systems to ensure ongoing alignment with Shaken requirements. In this sense, the process fosters ongoing stewardship of both the vehicle and the road environment, blending passion with responsibility in a way that few other regulatory systems manage to achieve.\n\nIn sum, Japan’s approach to car modification demonstrates that legality, safety, and personalization are not mutually exclusive. Modifications are not inherently illegal; they are governed by a framework that rewards careful planning, transparent documentation, and rigorous testing. The Shaken inspection stands at the heart of this framework, validating or denying the roadworthiness of a modified vehicle. For those who approach modification with respect for the rules and a commitment to quality, the system offers a reliable path from garage concept to street presence. It is a model of how a culture built on precision and pride can translate into a legal, safe, and ultimately more enjoyable driving experience. For further reading on the official process and standards, consult the Ministry of Land, Infrastructure, Transport and Tourism’s Shaken resources and guidance on roadworthy modifications, which provide authoritative details on inspection requirements and compliance expectations. https://www.mlit.go.jp/traffic/shaken/index.html

Subtle Power, Legal Lines: Navigating Japan’s Quiet Car Modification Ethos

In Japan, the question of whether car modification is permissible on public roads cannot be answered with a simple yes or no. The legality rests on a carefully balanced framework that foregrounds safety, environmental responsibility, and structural integrity rather than express rebellion or novelty. Modifications are allowed, but they must be designed, documented, and certified in ways that ensure the vehicle continues to perform within the parameters that the nation’s road regulations expect. The operative phrase is compliance: every alteration has to pass through the proper channels, be reflected in the inspection regime, and withstand the annual shaken—a rigorous examination that checks everything from braking performance to noise emissions. This system creates a paradox that many enthusiasts recognize: more than mere permission, it requires a disciplined craft that harmonizes individual expression with public safety. When a modification journey begins, it is less about flashing parts and more about forecasting how changes will behave in real traffic, how they will endure a long life on the road, and how they will survive the scrutiny of inspectors who are trained to spot deviations from the accepted standards. In this light, the legal landscape is less a gate and more a long, navigable road map, guiding builders to pursue improvements without crossing the line that keeps every street steered toward safety and reliability. For readers seeking the official frame, the Ministry of Land, Infrastructure, Transport and Tourism lays out the core expectations and procedures that govern vehicle modifications and inspections. The intent is not to curb creativity but to ensure that modifications do not compromise safety, emissions performance, or the fundamental geometry that keeps a car stable under a range of road conditions. The practical consequence is that many enthusiasts learn to work within limits, prioritizing precision, documentation, and repeatable testing over spectacle or sheer power. If the goal is a better-driving car that remains road-legal, the path is clear and, in many cases, deeply technical. A useful starting point for understanding how this works in practice is to consider how modifications are evaluated in relation to the shaken process and the standards that accompany it. This is not an abstract doctrine; it plays out in workshops, testing grounds, and every time a car is registered for a new inspection cycle. In other words, legality is a moving target that shifts with new safety innovations, evolving emissions rules, and the continual refinement of roadworthy criteria. Enthusiasts who embrace this dynamic often discover that the most satisfying results come from thoughtful, incremental improvements rather than dramatic, untested changes. The design philosophy centers on balance: upgrades that improve handling without altering the vehicle’s fundamental footprint, or interior refinements that enhance comfort while maintaining a neutral external silhouette. When done with care, such projects can elevate the driving experience without inviting regulatory friction. This is the essence of a culture that respects craftsmanship as much as compliance. A practical reminder for readers who want to dive deeper: modifications should be approached with a clear plan, cataloged changes, and a record trail that inspectors can follow. Documentation matters as much as the hardware itself. For those seeking guidance that frames modification within the legal process, a concise resource on legal car modifications can be a helpful starting point in conjunction with official guidelines. It’s not only about what is changed; it is about demonstrating that every change moves the vehicle closer to a legally compliant, safer state. The broader aim is not to erase individuality but to elevate it through responsible, verifiable engineering. The culture that supports this approach is not about the loudest exhaust or the widest fenders; it is about a quiet confidence in a well-tuned machine and the shared discipline of the community that respects the letter of the law as much as the spirit of performance. Throughout Japan, this philosophy manifests in a preference for refined, understated enhancements that improve dynamics, durability, and usability. The appeal lies in the confidence that comes from a car that feels engineered rather than patched together. Enthusiasts pursue precision components, tuned suspensions, and meticulously selected materials that integrate with the car’s baseline design. The result is a cadence of upgrades that are felt in the way the car behaves at cornering speed, braking threshold, and throttle response, rather than a chorus of visual theatrics. This approach extends to how communities gather and learn. Events and gatherings emphasize technical prowess, data-driven refinement, and peer review. They function as informal schools where builders exchange testing methods, measurement techniques, and prosaic but vital lessons about how a car should endure repeated track sessions and daily commutes alike. The social fabric of Japanese car culture—where ritual and craft are intertwined with the learning process—helps sustain a shared respect for safety and legality. In this environment, the legal framework does not appear as a suppressive regime but as a scaffold that supports sustained innovation. It invites a patient, methodical mindset: test, document, verify, and then test again. This is how a modification project matures from an idea into a road-legal, everyday performance upgrade that enhances the driving experience without compromising the car’s integrity. Readers who want to explore concrete pathways toward compliant modification will find that the rules are not arbitrary barriers but testable criteria that align with the long-term goals of reliability, safety, and responsible ownership. The emphasis on responsible customization resonates with engineers and enthusiasts alike, who see modification as a form of applied craft rather than a one-off display. The Japanese approach to alterations—call it subtle, precise, and purposeful—enables a spectrum of improvements that stay within the straits of law and public road use. It also foregrounds a sense of community that thrives on shared standards, peer oversight, and a meticulous attention to detail. In this sense, legal modification becomes a kind of disciplined art: a collaboration between the driver’s intention and the law’s safeguards, yielding vehicles that perform with quiet confidence. For those curious about how these principles translate to everyday practice, there is a straightforward pathway: select changes that improve safety or efficiency, obtain the necessary approvals, and maintain comprehensive documentation. Keep records of parts, technician certifications, and inspection results. Ensure that any alteration does not push the vehicle outside specified dimensions, noise levels, or emission limits. Above all, plan for how the car will behave under the jurisdiction’s annual shaken. This approach harmonizes personal aspiration with social responsibility, a balance that sits at the heart of Japan’s distinctive car culture. The broader takeaway is that legality breeds a form of artistry grounded in reliability. Enthusiasts who embrace this balance often discover that careful, well-documented upgrades—applied with patience and tested on controlled grounds—can transform a car into a personalized tool that remains a safe, trusted companion on public roads. For readers seeking further context on the legal and regulatory dimension, consult the official sources that outline the inspection criteria and modification procedures, as well as a survey of community practices that frame what it means to modify within a legal and cultural framework. Internal link: legal-car-modifications. External context provides a complementary perspective on how culture shapes perception of car modification beyond the regulatory lens. As you navigate this landscape, remember that the most enduring modifications are those that respect the road, the law, and the shared community that makes tuning a thoughtful, collective endeavor. For a broader cultural perspective on how these attitudes crystallize in public discourse, see BBC News.

External resource: https://www.bbc.com/news/world-asia-67819425

Final thoughts

Understanding the legal domain of car modification in Japan reveals a landscape rich with opportunity for car enthusiasts while ensuring safety, environmental compliance, and respect for tradition. Whether you’re modifying for performance, aesthetics, or personal expression, being aware of regulations and the necessary inspection processes fosters a responsible and enjoyable car modification experience. The fusion of regulation and creativity not only reflects Japan’s respect for quality but also underlines its unique car culture that continues to inspire enthusiasts around the globe.