For many automotive enthusiasts, the quest for customization and performance enhancements is a passion that drives countless modifications. As regulations loom and options become clearer, a key question arises: does PEMCO, known primarily for its aircraft modifications, allow car modifications? This article breaks down the circumstances surrounding PEMCO’s operations, contrasting their specialized focus on aircraft with the desires of car enthusiasts. Chapter one delves into PEMCO’s vehicle modification policies specific to automobiles. Chapter two showcases the company’s aircraft modification specialization, revealing why vehicle customization is not in their agenda. Lastly, we explore the regulatory frameworks impacting modifications across industries, further clarifying why PEMCO’s ultimate interest doesn’t translate to cars.

Beyond the Hangar: Why PEMCO’s Expertise Ends at Aircraft, Not Automobiles

When readers ask, “Does PEMCO allow car modifications?” the natural instinct is to look for a simple policy statement. The best available synthesis of the research materials, however, points to a clearer boundary: PEMCO is not a car-modification company. Its core focus is a highly specialized branch of engineering that sits squarely in aviation, not on four wheels. This distinction matters not only for enthusiasts seeking modification services but also for anyone trying to understand how corporate scope, regulatory frameworks, and risk management shape what a company can or cannot do. In short, PEMCO’s wheelhouse lies in the vast and demanding realm of aircraft engineering, where a different set of rules governs projects, approvals, and certifications than those that guide most automotive customization efforts. To understand why, we must start with what PEMCO actually does and how its work fits into the larger ecosystem of aviation maintenance and modification.

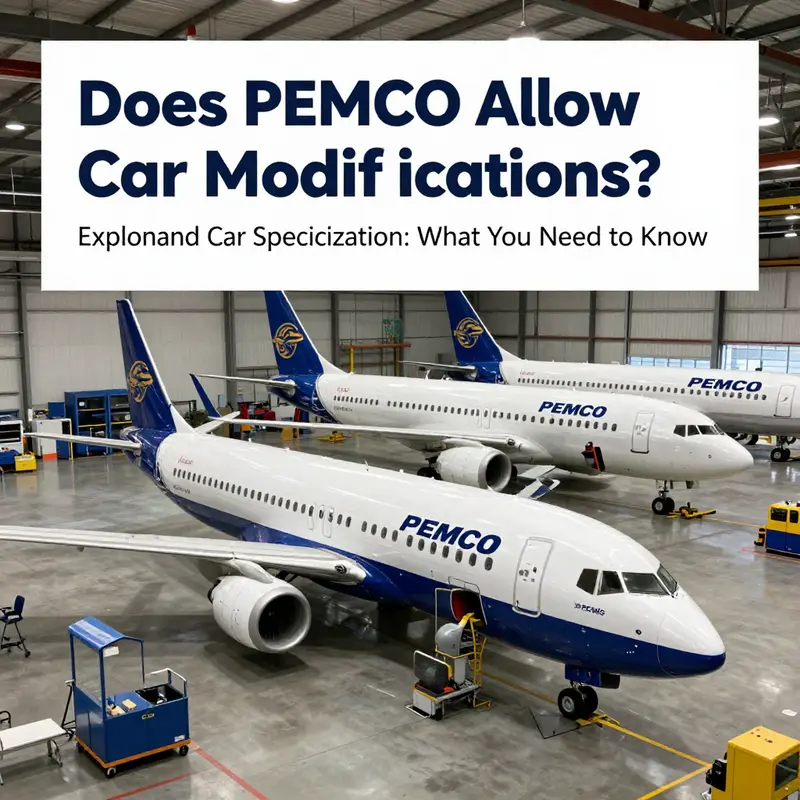

PEMCO Engineering & Maintenance Company is identified in the research materials as a specialized center within a broader aviation engineering group. Its mission centers on aircraft modifications, with a particular emphasis on passenger-to-freighter conversions — a niche that converts commercial airliners from passenger service to cargo operations. The Guangzhou Huadu Economic Development Zone project, described as taking place from 2022 to 2025, situates PEMCO within a collaborative context with a well-known airline-industry modification partner. The aim here is clear: to transform passenger aircraft into freighters, a transformation that requires meticulous design changes, structural considerations, weight and balance recalculations, cargo-handling system integration, and the most exacting certification processes known in aviation engineering. This is not a project that resides on the same spectrum as typical automotive aftermarket work. The scale, complexity, and regulatory oversight are of a completely different order of magnitude.

A crucial detail that anchors the chapter’s core message concerns PEMCO’s corporate trajectory. In 2017, PEMCO became part of ATSG’s Airborne Maintenance & Engineering Services, a shift that framed PEMCO as a specialized engine within a larger aviation-services organization. This acquisition underscored PEMCO’s identity as an institution oriented toward aviation-specific engineering challenges rather than toward the broader, consumer-facing world of automobile customization. The resulting organizational structure emphasizes a disciplined, highly regulated engineering culture — one that prioritizes safety, airworthiness, flight-critical systems, and the stringent documentation that aviation requires. In practice, that means PEMCO’s engineers, technicians, and project managers operate under aviation standards, with certification regimes, environmental controls, and quality management criteria that are specific to aircraft. Such a framework naturally does not translate into a policy or practice about modifying cars or approving car-modification projects.

From a policy perspective, the gulf between aircraft and automobile modification is defined by both regulation and risk. Aircraft are subject to aviation authorities, airline operators, airworthiness directives, and a global ecosystem of airframe certification. Every significant modification to an aircraft must pass through rigorous design approvals, structural analyses, load-path validation, and life-cycle considerations that extend beyond the capabilities and oversight structures typically applied to passenger cars. The safety implications are magnified by the fact that aircraft operate under entirely different regimes of maintenance scheduling, flight operations, and regulatory oversight. In contrast, car modifications are generally governed by automotive manufacturers, aftermarket industry standards, and insurance considerations that, while serious, do not culminate in the same kind of airworthiness documentation demanded by aviation. In other words, even if a company offers both kinds of services, the scopes, standards, and approvals do not overlap in a way that would permit a car-modification policy to be inferred from an aviation-focused profile.

What does this mean for stakeholders who are curious about PEMCO’s stance on cars? It means that there is no car-modification policy to reference because PEMCO does not operate as a provider of automotive modification services. There is no PEMCO policy in the context of “car modifications” that a consumer could consult, negotiate, or rely on for coverage, approval, or procedural guidance. The research materials clearly indicate that PEMCO’s expertise and projects sit in the domain of highly regulated aviation engineering — a field with its own distinct risk calculus, safety criteria, and governance structures. For readers, the practical implication is straightforward: if your goal is to modify a car, PEMCO is not the destination. If your aim is to understand the boundaries of a company’s capabilities, PEMCO’s published focus on passenger-to-freighter conversions reveals a strategic emphasis that is incompatible with automotive alterations.

As a reader loops back to the core question, it is worth noting why the aviation context matters for perceptions of modification policies in general. The aviation industry treats modifications as a change to a certified system. The certification basis, the need- for continued airworthiness, the requirement to demonstrate that each modification does not compromise safety, and the obligation to maintain rigorous documentation create a governance regime that is uniquely severe. The same degree of rigor does not automatically apply to cars, where modifications are more likely to influence performance, aesthetics, or resale value rather than airworthiness. This difference in governance helps to explain why PEMCO’s public-facing operations, as described in the research results, do not extend into the car-modification market. The company’s identity as an aviation specialist is not a reflection of an absence of interest in cars. Rather, it is a reflection of the specialized domain in which PEMCO functions and the regulatory ecosystems that shape its work.

For readers who are evaluating their own automotive modification plans, the clear takeaway is practical: PEMCO’s track record should be interpreted as a signal that this company does not offer car-modification services or policies. If you are trying to determine whether PEMCO would inspect, certify, or insure a car modification project, you should instead focus on automotive-modification specialists who operate under the relevant automotive regulations and insurance frameworks. These distinctions are not merely academic; they have real-world implications for safety, warranties, insurance coverage, and resale value. The broader lesson is that the choice of a modification partner should reflect the regulatory domain of the work being performed, the type of risk involved, and the appropriate certification paths that will ensure the modified vehicle remains compliant with laws and standards in your locale.

As you consider the topic further, you may wish to explore how modifications affect insurance and value in the automotive space. For readers curious about how modifications influence risk assessment, coverage terms, and premium calculations, there is a relevant body of guidance that sits squarely in the automotive domain. In particular, discussions about how modifications interact with insurance policies, how modifications impact resale value, and how to disclose changes to insurers can be crucial when planning any significant alteration to a vehicle. For readers who want to dive into that facet, a useful starting point is to consider resource material that discusses insurance implications around modified cars. The discussion there can help you to navigate the practical realities of automotive modification projects, independent of aviation considerations. For readers curious about how modifications affect insurance, see insurance for modified cars.

Returning to PEMCO itself, the key takeaway is that the company’s documented activity centers on aerospace engineering, not automotive modifications. The passenger-to-freighter conversion work described in the Guangzhou project, the acquisition by a larger aviation-services group, and the role of PEMCO as a specialized aviation-engineering center all reinforce the message: PEMCO’s capability and authorization are built to support airworthiness-critical projects. In that sense, the company embodies the disciplined approach required in aviation, where changes to the aircraft must be demonstrably safe, certifiable, and navigable through a tightly regulated process. This reality is not a limitation only for PEMCO; it highlights a structural reality about how industry sectors organize expertise and how policy implications flow from the domain in which a company operates.

The practical implications for a car-modification inquiry are clear. If you need a partner to perform, certify, or insure auto modifications, you should look beyond PEMCO and toward automotive specialists with explicit automotive licensing, warranties, and insurance-partner networks. The absence of car-modification policies within PEMCO does not indicate a deficiency; instead, it signals a clear boundary between aviation and automotive modification economies. This boundary helps consumers, insurers, and professionals align expectations, requirements, and processes with the right regulatory and safety frameworks. In other words, the correct parallel is not to search for cross-domain equivalence but to acknowledge domain specificity and pursue the path that matches the work’s nature, risks, and regulatory environment.

To close the loop on the internal navigation piece, readers who want to connect automotive modification topics with practical, policy-oriented resources should consider guidance that directly addresses car modifications. The automotive space provides a structured set of considerations for modification projects, including disclosure, insurance implications, safety standards, and resale effects. Engaging with resources that discuss these topics can help ensure that any car-modification endeavor proceeds with a clear understanding of risk, terms, and expectations. In practical terms, when you set out to modify a vehicle, you should start by identifying a reputable automotive-modification specialist, confirm the project’s compliance with local laws, and secure an insurer that explicitly covers the changes you intend to make. By grounding your plan in automotive-specific standards and policies, you can minimize uncertainty and protect your investment as you pursue your redesign or performance goals.

In sum, the question “Does PEMCO allow car modifications?” yields a definitive, policy-based answer: no, PEMCO does not provide car-modification services or policies because its core business and expertise lie in aviation engineering, particularly aircraft modifications like passenger-to-freighter conversions. The company’s corporate evolution, including its integration into ATSG’s Airborne Maintenance & Engineering Services, reinforces this focus. The aviation-specific nature of PEMCO’s work means that any modification policies, approvals, or assurance processes are framed by airworthiness and aviation safety standards, not by automotive modification guidelines. For readers eager to pursue car modifications, the path lies elsewhere — with automotive specialists who operate within automotive regulations and with insurers who understand how modifications affect coverage, risk, and value. As a practical follow-through, consider consulting automotive-modification resources for policy implications, and remember to disclose changes to your insurer as required by your specific policy terms. External resources from aviation authorities can provide helpful context for how aviation modifications are evaluated and certified, while automotive resources will guide you through the more familiar terrain of adjusting a car. External resource: https://www.faa.gov

From Skies to Silence on the Asphalt: Why PEMCO Keeps Its Focus on Aircraft Modifications

PEMCO, or Pan American Engineering and Manufacturing Company, resides in a domain where engineering meets the rarefied requirements of air travel. The material available about PEMCO emphasizes aviation work—engineering, modification, maintenance, repair, and overhaul of aircraft—over anything related to cars or the automotive sector. The research landscape paints PEMCO as a company whose signature strength lies in turning passenger jets into cargo aircraft, a process often described in industry terms as passenger-to-freighter (P2F) conversions. Within the global aviation ecosystem, those conversions are not mere upgrades; they are certified, high-stakes transformations that reverberate through airworthiness certificates, flight operations, regulatory approvals, and the delicate balance of a loaded airframe. As a consequence, PEMCO’s strategic footprint appears to be intentionally skewed toward airframes, cargo systems, and the specialized engineering discipline that keeps airplanes safe, efficient, and compliant from the hangar to the sky. This background matters when one asks about car modifications; the straightforward answer, drawn from PEMCO’s documented focus, is that PEMCO does not, and does not intend to, modify cars or endorse automotive alterations. The company’s safety and reliability calculus rests on different pillars than those governing automotive work, which already sets the stage for a broader discussion about why the aviation sector, with its unique regulatory regime, tends to keep its innovations within the realm of flight rather than the roadway.

To understand the scope and boundaries of PEMCO’s work, it helps to ground the conversation in the core competencies that define the organization. The aviation domain demands an integration of structural engineering, systems integration, and precise weight and balance management. PEMCO’s reputation in aircraft conversion, particularly the modification of certain commercial aircraft into freighters, points to a specialized proficiency in reconfiguring interior layouts, strengthening key load-bearing elements, and adapting cargo handling systems to new mission profiles. This is a discipline where a miscalculation can affect center of gravity, wing loading, and clearance envelopes, with direct implications for takeoff, climb performance, fuel efficiency, and landing dynamics. The environment in which PEMCO operates is crowded with regulatory oversight from aviation authorities around the world. Every modification that changes the performance envelope of an aircraft must be validated through engineering analyses, flight testing timelines, and comprehensive documentation packages that accompany a type certificate amendment or similar regulatory pathway. The rigor embedded in this process is not a mere procedural hurdle; it is the safety framework that permits airlines to operate in diverse airspaces under stringent performance standards. The takeaway here is not simply that PEMCO builds cargo planes; it is that their engineering culture is built to respond to the kind of risk calculus, traceability, and lifecycle support that aviation demands. In short, their specialization is a constellation of capabilities tailored to airworthiness, not to automotive experimentation.

The Guangzhou Huadu Economic Development Zone project illustrates a strategic axis around which PEMCO’s current narrative revolves. The plan to convert passenger Boeing 737s into freighter configurations, conducted in collaboration with a well-known aviation modification enterprise, signals a phased public commitment to expanding cargo operations. The timeline from 2022 to 2025 frames this as a long-duration, multi-stage effort, likely involving design iterations, supply chain coordination, regulatory alignment, and workforce training. Projects of this magnitude require cross-functional teams that blend structural engineers, systems integrators, supply chain experts, and flight-test professionals. The aviation context also demands that any alteration to the airframe—the physical skeleton of the aircraft—must be thoroughly vetted against airworthiness standards before it can carry out its mission. For PEMCO, this means the work remains anchored in a sphere where precision, certification, and long-term serviceability drive every decision. The message that emerges is not about neglect of other domains but about a strategic concentration of resources where PEMCO’s track record and institutional knowledge offer the greatest value: airframes, cargo systems, and the engineering ecosystems that support safe, reliable flight operations.

In this light, the question about car modifications becomes a question of different value propositions and different risk profiles. Automotive modifications, even when pursued by skilled technicians, operate in a regulatory landscape that is distinct from aviation. Car tuning, aftermarket enhancements, and cosmetic changes—whether pursued for performance, aesthetics, or personalization—must contend with a patchwork of safety standards, warranty implications, and insurance considerations that vary by jurisdiction and insurer. The automotive domain emphasizes roadworthiness and compliance with traffic laws, which are governed by a set of standards that do not mirror the airworthiness regimes that govern aircraft. The intricacy and depth of certification for an aircraft modification cannot be overstated; airworthiness directives, airframe changes, weight and balance recalculations, and new runway performance calculations are a different family of requirements from those that govern modifications to a passenger vehicle. PEMCO’s lack of involvement in car modifications is therefore not a matter of capricious policy but a reflection of a carefully cultivated risk-management and competency strategy designed for flight rather than for asphalt.

A further layer of why PEMCO does not venture into automotive modifications lies in the distinct epistemic communities that govern these two worlds. Aviation engineering thrives on a near-obsessive discipline for documenting every change, every bench test, every flight-test result, and every maintenance action in a traceable chain of custody. The reliability demands for an airframe are measured against international standards and the reputational and financial penalties that come with any lapse in safety. Automotive modification communities, while also professional and earnest, operate within a different ecosystem that prioritizes things like warranty boundaries, consumer expectations, and market-driven timelines. The material science, the fatigue analysis, the repair methodologies, and the lifecycle management practices diverge enough that cross-domain expertise would require a recalibration of a company’s entire engineering and regulatory apparatus. PEMCO’s leadership, therefore, has likely found it more efficient and safer to stay the course within aviation, leveraging long-standing relationships with airlines, MRO providers, and certification authorities that reward depth over breadth in this particular sector.

To speak more concretely about what PEMCO does within aviation, the company’s core offering extends beyond mere airframe modification. The MRO support ecosystem—the ongoing engineering consultation, weight and balance management, and tailored electronic solutions—plays a crucial role in keeping aircraft operational and compliant across their service life. Engineering consulting in this space includes structural assessments, load path analyses, and integration strategies for new cargo systems or interior reconfigurations. Weight and balance management is not a peripheral concern; it is a central discipline that determines how much payload an aircraft can carry safely and efficiently, how it behaves during takeoff and landing, and how fuel burn is affected by payload distribution. The software tools and procedures involved in this work require meticulous data handling, calibration, and validation against time-sensitive flight data. The technical colleagues who perform these tasks must be fluent in aviation-grade standards, such as those governing load constraints and certification compliance. PEMCO’s capacity to deliver these services on a global scale—paired with technical assistance and training for operators around the world—speaks to a business model grounded in reliability, repeatability, and the ability to support diverse fleets under multiple regulatory regimes.

If one considers the broader implications for customers who own cars or who contemplate modifying vehicles, PEMCO’s example becomes a cautionary tale about scope and competence. The aviation example demonstrates how a deep literacy in one realm—airworthiness, regulatory oversight, and long-term lifecycle management—produces results in safety and reliability that are not easily transferable to automotive contexts. A decision-maker contemplating car modifications would need to navigate an ecosystem that includes not only the feasibility and desirability of particular modifications but also the potential impact on insurance coverage, resale value, and warranty status. This is precisely why automotive modifications often require specialized automotive service providers who understand the patchwork of state or national regulations, insurer policies, and consumer expectations. The automotive domain has its own set of ethics and best practices, many of which revolve around risk disclosure, the need for proper approvals within financing or leasing agreements, and the realities of consumer financing where modifications can affect loan terms and residual values.

The interplay between safety, reliability, and regulatory compliance is where PEMCO’s aviation-focused operations illuminate a broader principle: specialization can be a strategic asset. By cultivating a deep repository of knowledge about airframes, cargo systems, and the regulatory machinery that governs airworthiness, PEMCO creates a value proposition that is hard to replicate outside its chosen sector. This is not a commentary on any inherent superiority of aviation over automotive work; rather, it is an acknowledgment that the rules, risks, and requirements that shape these domains demand distinct competencies. In aviation, a single misstep can have immediate, irreversible consequences for flight safety and public well-being. The consequence of that reality is a culture of meticulous engineering, exhaustive documentation, and conservative project sequencing that may seem extreme to automotive practitioners but is entirely appropriate for air operations. For PEMCO, this translates into a firm boundary: the company’s capabilities and credentials are aligned with aircraft modification and related support services, not with car modifications or automotive alterations.

Within this framing, it becomes meaningful to consider how readers who are car enthusiasts or vehicle owners might navigate their own modification ambitions. The practical takeaway is to seek automotive specialists who are equipped to handle the local regulatory environment, warranty questions, insurance implications, and the performance or aesthetic goals that drive car modifications. Such specialists can provide a tailored risk assessment, a clear plan for approvals if necessary, and a path to documentation that supports future resale or lease considerations. When a modification project intersects with financing arrangements or lease agreements, as many car owners experience, the emphasis on clear communication with lenders, insurers, and dealers becomes even more critical. In these contexts, a company’s demonstrated competence and focus—as PEMCO shows for aviation—can be an important proxy for the reliability of the service provider you choose in the automotive space. If a reader seeks broader guidance on how modifications might influence resale value, there is a wealth of automotive literature that discusses the nuanced relationship between customization and market perception. In particular, discussions that address the long-term implications of modifications on resale value and the insurance landscape can offer practical insights into how to approach automotive projects with a realistic view of risk and reward. For a deeper dive into this aspect, one can consult analyses such as the piece on car modifications and resale value, which explores how different kinds of modifications influence market perception, buyer interest, and price trajectories in the used-car market.

In the end, the alignment of PEMCO’s corporate capabilities with aviation rather than automotive work is not merely a matter of business preference but a reflection of the competencies, regulatory commitments, and safety imperatives that define each field. The company’s documented emphasis on converting passenger airframes into cargo configurations, along with ongoing MRO support and global client services, constitutes a complete ecosystem designed to sustain and optimize airworthiness. The decision to refrain from car modifications is a logical extension of this ecosystem, rooted in the belief that the optimal value for PEMCO’s clients—and for the broader public—emerges when engineering excellence remains tightly coupled to the domain that most directly bears the consequences of design choices: flight. For readers who are curious about the cross-cutting questions of modification, risk, and value, PEMCO offers a compelling case study in how specialized knowledge translates into responsible, dependable outcomes in a field where safety is inseparable from the engineering process. And while the automotive world may offer opportunities for personalization and performance enhancements, the PEMCO example reminds us that not all engineering ambitions travel well across domains; some are best kept where the environment is governed by airworthiness and the precise, auditable standards that sustain flight.

For readers who want to explore more about how car modifications are discussed in automotive contexts, a broader conversation exists online about the relationship between customization and resale value, insurance implications, and the legal considerations surrounding modifications. This material can serve as a practical companion piece to the aviation-focused narrative, offering a grounded perspective on how modifications influence ownership experiences in the automotive sphere. If you’re curious to see a detailed exploration of how car modifications and resale value interact, you can review a resource that examines these dynamics in depth. As always, when considering any modification, it is essential to consider safety, compliance, and long-term implications for value and risk. PEMCO’s story reinforces the principle that deep expertise in a specific domain yields the most trustworthy outcomes, and in this case, that domain is aircraft modification and support—far from the arena of car customization.

External reference: https://www.pemco.com

Internal link for readers exploring automotive modification considerations: car-modifications-and-resale-value

Why PEMCO Doesn’t Permit Car Modifications: Navigating Aviation Regulation, Industry Boundaries, and What It Means for Car Enthusiasts

When readers ask whether a company can modify a car, the instinct is to look for a simple yes or no. Yet the answer often hinges on where a business sits in the regulatory landscape and what its core competencies are. In the case of PEMCO, the straightforward response is not just a yes or no about autos, but a clear statement about scope, safety, and compliance. The heart of the matter lies in understanding the organization’s primary focus and the strict frameworks that govern its operations. The information gathered shows PEMCO is primarily engaged in the domain of aviation—specifically, the complex art of turning passenger aircraft into cargo configurations. This is a field defined by high-stakes safety, precise engineering, and rigorous certification processes that operate under aviation authorities rather than the agencies that oversee road vehicles. The organization’s current project, conducted in a dedicated industrial zone within a major economic development area, is framed as a collaboration with an established modification entity within the airline industry, and the timeline spans several years. Taken together, these details reveal a deliberate specialization that leaves car modifications outside PEMCO’s mandate. This alignment with aircraft systems and airworthiness is not incidental; it is the natural outcome of a regulatory ecosystem designed to manage the complexity and risk associated with flying machines. To claim PEMCO’s involvement in automobile alterations would blur lines that aviation regulators actively maintain between air and land transportation, and it is this separation that ultimately explains why PEMCO does not and cannot offer car modification services.

The regulatory architecture that governs PEMCO’s operations is not merely a bureaucratic backdrop; it is the framework that shapes every decision, design, and verification step. In aviation, modifications to aircraft—whether structural changes to the airframe, updates to avionics, or changes to the cargo loading configuration—require a stringent certification path. This typically involves extensive design approvals, rigorous testing, and ongoing compliance surveillance to ensure that any alteration preserves or enhances airworthiness. The pathway often culminates in a designation like a supplemental approval that is unique to the aircraft’s intended use and its operating environment. Such processes are designed to minimize risk in the air, where the margin for error is infinitesimal and the consequences of failure are severe. PEMCO’s specialization within this regime means its engineers and technicians are trained to navigate complex airworthiness requirements, safety standards, and the lifecycle management that accompanies large transport aircraft.

One of the enduring truths about aviation modifications is that they do not operate in a vacuum. They sit at the intersection of design, manufacturing, maintenance, and regulatory compliance. When PEMCO undertakes work related to aircraft modifications, they engage with a system that expects traceability, documentation, and demonstrable proof that every change harmonizes with the aircraft’s type design and its operational envelope. This is not merely about achieving a desired outcome; it is about proving that the modification can be integrated safely into a fleet that carries passengers and cargo across vast distances, day after day. The rigorous approach extends beyond the initial certification. The aviation industry mandates ongoing monitoring, recurrent inspections, and periodic revalidation to accommodate cumulative wear, evolving standards, and updates to the operating environment. In short, the aviation modification framework demands an unequivocal commitment to airworthiness that remains constant across the aircraft’s lifecycle. When a company’s primary business is aligned with this framework, its value proposition rests on expertise in ensuring that every change is reversible in the sense of maintaining safety, rather than on expanding into other domains such as automotive alterations that operate under entirely different constraints.

This distinction between air and land safety is more than technical nuance. It shapes every practical implication for enthusiasts who might wonder whether a service provider in one field could pivot to the other. Automotive modifications inhabit a world governed by different authorities, with different risk appetites and different standards for vehicle integrity on public roads. In the United States the regulatory tapestry is woven through agencies like the national highway safety and transportation bodies, which set guidelines for how cars can be modified without compromising safety and legality. In other countries, ministries and departments of transport or equivalents play similar roles, but the specifics can vary. The essential point is that automotive modifications are evaluated against roadworthiness criteria, crash safety standards, emissions considerations, and consumer protections that differ substantially from aviation’s airworthiness paradigm. This divergence matters not only for compliance but for the commercial viability of any modification work. A company expertly positioned to manage aircraft safety is, by its nature, not trained or chartered to navigate the maze of automotive regulations, which demand a different skill set, certification culture, and risk-management philosophy.

For vehicle owners and modifiers, the upshot is practical and often overlooked: a service that specializes in one high-stakes domain does not automatically translate into capability in another. PEMCO’s public-facing profile centers on airframe maintenance, aerodynamic efficiency, systems integration, and the complexities of cargo configurations for large passenger jets. There is no indication in the available materials that PEMCO maintains the necessary regulatory authorizations, design libraries, safety case frameworks, or maintenance discipline required to approve land-based vehicle modifications. It would be inappropriate to imply that a company with such a focus could seamlessly extend its competencies to cars, especially when doing so would require compliance with an entirely separate ecosystem of standards and enforcement. The clear implication for readers is not a denial that PEMCO could ever help with cars in some vague sense, but a grounded understanding that the company’s operations are designed to meet aviation safety, not automotive safety, requirements.

The distinction between aircraft modifications and automotive work is not merely about where the mechanical effort is applied. It is about the standards that must be proven and the ways in which those standards are audited and enforced. In aviation, modifications are part of a regulated developmental lifecycle that demands traceability, engineering rigor, and continuous oversight. A modification that affects an airframe, a fuel system, or an electrical system must demonstrate that it will perform reliably under diverse flight conditions and throughout the aircraft’s service life. A change is not approved by a single engineer in a workshop; it must be validated by a certification body, aligned with the manufacturer’s design data, and supported by a robust maintenance program. The consequences of failure in flight are a constant reminder of why the industry maintains such exacting procedures. In the automotive world, the regulatory emphasis shifts toward roadworthiness pering, tire and brake compliance, emissions, and consumer protection. The risk calculus and oversight mechanisms are different, and the cultural expectations around modifications—whether for performance, aesthetics, or utility—are shaped by a different set of incentives. PEMCO’s long-standing focus on airworthiness framed within this aviation-centric culture explains why car modifications do not fall within its service portfolio.

With that understanding, it becomes evident why the research results describe PEMCO as an enterprise whose core function is aircraft-oriented. The strategic emphasis, as reported, is on advanced engineering for large, complex airframes and their cargo capabilities. The presence of a collaborative project to convert passenger fleets into freighters underscores a commitment to a niche but highly regulated field. If one tracks the logic further, it becomes clear that PEMCO’s processes, staffing, and governance are optimized to meet aviation’s exacting standards. The regulatory steps—from securing design approvals to performing maintenance checks and ensuring continued airworthiness—dominate the operational playbook. Under such conditions, offering or even permitting automotive modifications would require a fundamentally different regulatory alignment, a different cadre of safety cases, and a separate chain of accountability. It is this alignment, more than anything else, that clarifies why PEMCO does not, and cannot, provide car modification services.

For readers seeking a broader vista on how to navigate automotive modifications within the law, there is value in consulting general automotive guidelines that map the terrain of permissible changes and their consequences. A practical entry point can be found in the automotive modification guide, which outlines common paths and pitfalls for car enthusiasts who want to stay compliant while pursuing personal customization. This guide offers a structured overview of typical modifications, their potential impact on insurance and resale value, and the kinds of documentation that can help protect a modifier and the vehicle owner alike. The link provides a useful bridge from the aviation-centered lens of PEMCO to the world where car enthusiasts operate, reminding readers that every jurisdiction may have unique rules and that responsible modification requires respect for those rules rather than a shortcut through regulations. See the car modifications guide for an accessible primer on the landscape of permitted and restricted changes.

Beyond the policy and process, the practical implications for car owners involve a careful balance between desire, feasibility, and safety. Enthusiasts drawn to transformations—whether for performance gains, aesthetic changes, or functional upgrades—must consider how modifications intersect with the vehicle’s warranty, the potential effects on insurance premiums, and the risk of running afoul of traffic laws. Insurance implications, for instance, can be complex. Some insurers adjust premiums after modifications, especially those that alter the vehicle’s power, handling, or safety systems. Others may require additional inspections or declare modifications as pre-existing conditions that influence coverage. The resale value of a modified car can also swing in unpredictable ways depending on market trends, the quality and rarity of the modification, and the buyer’s preferences. In short, car modifications have layers of consequence that extend well beyond the immediate engineering task. They touch legal compliance, financial exposure, safety responsibility, and long-term ownership experience. The aviation-focused model embodied by PEMCO’s operations serves as a reminder that when a project sits at the boundary of safety-critical domains, a conservative, regulated approach—not only to design but to ongoing monitoring—takes precedence. While the desire to personalize a vehicle remains legitimate, it must be pursued within a framework that ensures safety for occupants and other road users, and that adheres to the letter of the law.

In considering the broader meaning of PEMCO’s aviation-centric stance for readers, there is also a lesson about organizational boundaries and the way expertise travels between industries. The transfer of knowledge from one highly regulated sector to another is not impossible, but it is rarely seamless. The competencies involved in safely modifying an aircraft—structural integrity, redundancy, fail-safety, and systems integration—do not automatically translate into the land-based chassis, brakes, steering geometry, and automotive electronics that govern cars. The knowledge a team must master to certify a change on an airplane is not the same knowledge required to certify a change on a street-legal vehicle. Even when the underlying engineering discipline—materials science, fatigue analysis, systems engineering—appears transferable, the regulatory gateways, testing regimes, and risk acceptability criteria are distinct enough to require specialized teams for each domain. This is not a judgment about capabilities but a recognition of the nature of certification culture and public accountability. PEMCO’s emphasis on airworthiness, therefore, reflects a strategic choice to concentrate resources where the regulatory and safety systems clearly align with the company’s core strengths.

For readers who hold a fascination with both aviation and automotive engineering, the divergence between these two worlds offers valuable perspective. The aviation domain represents a frontier where risk is existential, and the safeguards are correspondingly stringent. The automotive domain represents a more diverse ecosystem where risk, while still serious, is managed through a different mix of standards, enforcement, and consumer protection. Understanding this distinction helps explain why a company may be a leader in one field while choosing not to operate in the other. It also underscores the importance of engaging with the right specialists for automotive work. If the goal is to modify a car while staying within legal and safety boundaries, the best path lies in selecting authorized automotive professionals who understand the exact regulatory demands of the respective jurisdiction. In this sense, PEMCO’s example can serve as a cautionary tale about scope, responsibility, and the careful stewardship of safety across transportation modes.

The concluding takeaway is not simply a binary verdict on whether PEMCO will modify cars. It is a reminder that every organization’s capabilities are bounded by a complex lattice of regulatory expectations, industry standards, and safety imperatives. PEMCO’s public profile, grounded in aircraft maintenance and passenger-to-cargo conversions, illustrates how tightly regulated the aviation world is and why that regulation matters so profoundly. It also highlights the importance for readers to pursue automotive modifications with a clear understanding of legal requirements, the ramifications for safety, and a commitment to engage specialists who operate within approved frameworks. For those exploring customization, the road ahead is not closed; it is simply delineated by a different compass—one that points toward roadworthy, lawful, and well-documented work conducted by qualified automotive professionals. In the end, this clarity is precisely what protects both enthusiasts and the broader public as they transform vehicles while upholding the highest standards of safety and accountability.

External notes for further reading on the aviation-focused regulatory environment and PEMCO’s area of specialization can be found here: https://www.airbornemaintenance.com/

To anchor this discussion in practical terms for automotive enthusiasts seeking general guidelines, consider the automotive modification guide linked earlier. It offers a practical, reader-friendly overview of how changes are evaluated, the kinds of documentation that are typically expected, and how to approach modifications in a way that balances personal goals with legal obligations. The guide is not a substitute for jurisdiction-specific advice, but it provides a solid foothold for readers as they navigate the complex terrain of car customization. In parallel with this, individuals should stay abreast of any local regulations that could affect modifications, including roadworthiness standards, safety inspections, and insurance requirements, as these factors can have immediate and tangible effects on both the feasibility and the financial implications of any planned changes.

In summary, PEMCO’s focus remains squarely on aviation, where the procedures that govern modifications are built to ensure airworthiness and flight safety. Automotive modifications operate within an entirely different regulatory landscape, one that calls for careful compliance, professional guidance, and a vigilant eye on safety, insurance, and legal standards. This alignment of expertise and governance clarifies why PEMCO does not offer car modification services and reinforces the importance of pursuing automotive projects through channels designed for land-based transportation. The chapter thus closes with a clear, grounded understanding: when it comes to PEMCO, the skies define the boundaries of modification—not the road—and those boundaries safeguard the integrity of both air travel and road safety for everyone.

Final thoughts

While automotive enthusiasts are constantly seeking new ways to personalize and enhance their vehicles, it is clear from our exploration that PEMCO does not support or engage in car modifications. Their operations are firmly rooted in aircraft modifications, particularly focusing on converting commercial planes to freighters. Understanding this distinction not only clarifies PEMCO’s role in the industry but also helps car enthusiasts find appropriate avenues for their modification passions. Ultimately, enthusiasts are best served by engaging with specialized companies that cater to automotive modifications.