With the rising popularity of LED modifications in vehicles, ensuring these enhancements operate seamlessly is crucial. Short circuits can not only hinder performance but also pose significant safety risks. This guide is tailored for hobbyist car modifiers, professional tuners, and restoration enthusiasts alike, providing a thorough exploration of how to methodically identify shorts in LED circuits. Each chapter will delve deeper, covering initial safety checks, rigorous inspection techniques using multimeters, and thorough component testing to empower you in troubleshooting effectively.

First Steps to Safety: Isolating and Pinpointing Shorts in LED Car Modifications

Safety and first isolation steps

Start by making the car electrically safe. Disconnect the negative battery terminal. Leave it disconnected while you work. This removes risk of sparks and protects sensitive electronics. Remove the fuse for the affected LED circuit next. Pulling that fuse keeps the circuit isolated. Work with a clean, well-lit area and use insulated tools. Wear safety glasses and gloves if wires are damaged or insulation is melted.

A careful visual sweep often solves the mystery. Follow the LED wiring from the power source toward each light. Trace every splice and connector. Look for melted insulation, exposed copper, chafing where wires pass through holes, and burn marks. Check common stress points: where harnesses run near the engine, through door sills, behind trim panels, and around mounting brackets. If wires are zip-tied too tightly, they can rub through. A pinch from a clamp or screw can cut insulation over time.

Connectors are frequent failure points. Unplug each connector in the affected branch and inspect the pins and sockets. Bent or corroded pins can arc and overheat. Replace or clean connectors with contact cleaner and a light brush if corrosion is light. For badly damaged connectors, install replacements and use heat-shrink tubing for protection.

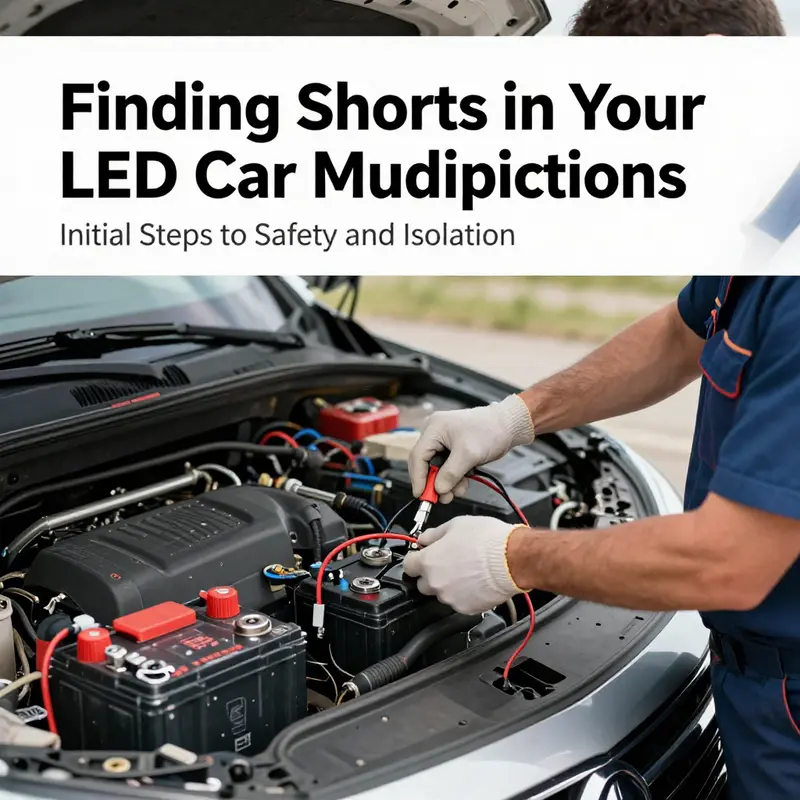

When the visual check finds nothing obvious, use your multimeter. Set it to continuity mode first. Continuity mode beeps when a low-resistance path exists between probes. With the fuse removed, place one probe on the fuse’s power side and the other on the fuse’s load side. If the meter beeps, there is continuity across the fuse location. That indicates a short somewhere in the circuit downstream. If the meter shows near zero ohms from power to ground, you are seeing a solid short to chassis.

If continuity confirms a short, isolate by dividing the circuit. Disconnect the LEDs and any intermediate modules, one section at a time. After each disconnection, repeat the continuity test. When the beeping stops, you have isolated the suspect section. This process of elimination quickly narrows the search area. Work methodically and document what you disconnect.

Ground shorts deserve special attention. A live conductor contacting the vehicle body is a common cause. To test for this, place one meter probe on the fuse-holder’s positive terminal. Put the other probe on a known good chassis ground, such as an engine bolt or frame rail. If the meter beeps, the circuit is shorted to ground. Next, trace the harness along its route. Look for wires that contact metal edges or reach into water-prone areas. Pay attention to wire passes through body panels and bulkheads.

When you suspect a ground short but cannot find it visually, use a length of cloth tape to gently wrap suspect sections. The tape temporarily insulates sharp edges. Wiggle harnesses while testing continuity to reproduce the short. Movement may reveal intermittent chafing that only appears under vibration or load.

If the short persists and you have a clamp meter, measure current draw from the fused feed with the fuse removed but the circuit connected to ground through a controlled load. A high current reading confirms a heavy short. Power-probing tools let you apply low voltage while measuring current and voltage drop. These tools speed diagnosis but require caution. Always respect polarity and never apply probing voltage to sensitive modules without knowing their ratings.

Inspect LED modules themselves. High-quality LEDs usually last long, but poor manufacturing can cause internal shorts. Remove the LED module and hold it in your hand. Gently shake it while listening for loose parts or rattles. Look for heat discoloration near connectors or driver boards. If the module has a replaceable driver, open the housing carefully and inspect solder joints and PCB traces. Cold solder joints, cracked traces, or burned components can create shorts under power.

If you find a suspect LED module, substitute a known-good lamp or module temporarily. Reconnect the circuit with a proper fuse and battery, and test. If the short disappears, the module was the fault. Replace the module with a higher-quality part and re-protect solder joints with conformal coating or epoxy where appropriate.

When isolating the short, work from the simplest connections first. Disconnect plug-and-play components and then move on to hardwired sections. If the wiring was modified during installation, follow the modification path. Mod installations often add splices and butt connectors. Poorly crimped joints or exposed solder can make intermittent shorts. Replace suspect crimps with properly sized connectors and heat-shrink tubing.

Document what you test. Use masking tape and a marker to label disconnected plugs and wires. A clear map prevents reconnecting the wrong circuits. Photograph tricky junctions before unplugging so you can restore routing correctly. Good documentation saves time and reduces the chance of introducing new faults.

Use a test light as a low-cost diagnostic aid. A test light will glow when current flows. Connect the test light to the fused power feed and touch the probe to sections of the harness. It will indicate live shorts and allow you to follow the current path visually. Test lights are especially useful when shorts occur only under certain conditions, like when the car is running or when a door is closed.

A short-finder tool or circuit tracer helps when wiring runs behind panels. These tools inject a tone or signal into the wire and let you follow it with a probe. They work well for long runs or hidden branches. Use them to find breaks, shorts, or unexpected ground contacts without disassembling the entire interior.

When you locate a damaged wire, cut out the compromised section. Use soldered splices for a permanent repair, or use high-quality butt connectors if soldering is not feasible. Always cover splices with adhesive-lined heat-shrink tubing. The adhesive seals the joint and keeps moisture out. Route repaired wires away from moving parts and sharp edges. Add rubber grommets where wires pass through metal panels.

If a harness shows signs of repeated damage, consider replacing the entire harness or rerouting the wires. Constant repairs signal a bad routing choice. Reroute wires behind trim, away from heat sources, and over smooth surfaces. Use additional protective conduit or split loom for sections near the engine or exhaust.

Connector corrosion is best addressed by replacing the connector if pins are pitted. For light corrosion, a cleaning with a small brush and contact cleaner helps. After cleaning, apply a thin film of dielectric grease to seal the contacts and prevent future corrosion. Grease also helps maintain good electrical contact under vibration.

Sometimes shorts hide inside control modules or relay sockets. If your LED installation added a switchbox or external controller, unplug it and test the circuit. Controller boards can fail and present as shorts. Inspect boards for bulging capacitors, scorched resistors, or melted plastic. Replace any suspect controllers with units rated for automotive use and proper voltage.

Fuse selection matters during testing. Use a fuse of the correct rating when powering the circuit to test. Never substitute a higher-rated fuse to avoid blowing during testing. A temporary inline fuse with an ammeter can help identify current draw while still protecting the circuit. Always replace blown fuses with fresh ones that match the circuit rating.

After repairing the short, reinstall the fuse and reconnect the battery. Turn the circuit on briefly and watch for smoke, sparks, or overheating. Check LED behavior and current draw. If everything looks stable, run the system through normal conditions. Open and close doors, jiggle harnesses, and drive short distances if necessary. Re-test after a short drive; heating and vibrations can reveal remaining problems.

Take preventive steps to avoid future shorts. Use grommets wherever wires pass through metal panels. Avoid routing wires near exhaust components and sharp edges. Secure harnesses with good-quality zip ties or clamps. Leave a small service loop near connectors to relieve tension. Use wire looms in exposed areas and maintain separation between power and signal wires to reduce interference.

Quality of components matters. Cheap LED modules and controllers are more likely to fail. Invest in parts designed for automotive conditions. Look for waterproof ratings and proper thermal management. Replace suspect hardware with higher-rated components when feasible. While this increases upfront cost, it reduces downtime and repairs.

Keep a small toolkit with insulated pliers, a multimeter, a test light, a few spare fuses, heat-shrink tubing, and connector kits in your garage. Having these items ready reduces test time and helps you perform clean, lasting repairs. Label spare fuses for the circuit ratings you most often deal with.

When to call a professional is an important judgment. If the short involves airbag circuits, engine management systems, or complex factory harnesses, seek a trained technician. Modern vehicles have multiplexed networks and sensitive modules. Improper testing can cause costly damage. For most LED lighting shorts in aftermarket branches, careful, methodical work resolves the issue safely.

If you want step-by-step installation guidance to avoid wiring problems in future projects, refer to a practical guide on how to install modifications car for routing and best practices. The guide covers routing, securing, and protecting wires during installation to reduce risk of shorts.

For further reading on tracing and repairing automotive shorts, consult a trusted repair manual or online technical resource. One practical article explains detailed troubleshooting steps and diagrams for automotive shorts. It provides useful procedural checklists you can follow during diagnosis: How to Detect and Fix Electrical Shorts in Automotive Wiring – AutoZone

Tracing a Hidden Fault: A Patient, Methodical Hunt for Shorts in LED Car Modifications

Troubleshooting a short in LED car modifications is less a race against time than a careful, detective-style search for the faintest clue. The goal isn’t simply to get the lights back on; it’s to understand where the fault hides, why it behaves the way it does, and how to prevent a repeat without compromising safety or performance. When you approach the task with a calm mindset, the process becomes almost ritualistic: safety first, observation, measurement, isolation, and, only then, replacement or repair. This chapter guides you through a cohesive, end-to-end exploration that blends practical inspection with precise electrical testing. It highlights the way a problem may present itself in plain sight or lie hidden within a loom of wires and connectors, waiting to reveal itself only when the system is loaded, warmed by the engine, or flexed as you drive over a rough road. The narrative here is designed to mesh with the broader article topics about safe, effective LED modifications and the decisions that keep electrical systems reliable, while also underscoring how meticulous work in the shop translates to long-term peace of mind when you’re on the road.

The starting point for any successful diagnosis is safety. Before you touch a single wire, turn the vehicle off and disconnect the battery. Negative terminal first, then positive, to avoid any accidental re-energizing that could surprise you with a spark or a dangerous arc. If you can access the fuse box without forcing the lid or stressing harnesses, remove the fuse tied to the problematic circuit. This simple act shifts your workspace from a live system to a safe schematic, letting you test with confidence rather than fear. With the fuse removed, you’ve created a controlled environment—one that minimizes the risk of collateral damage and sets up a clear baseline for further checks. In practice, this is also where you start to map the system in your head: where power comes in, where it travels, and where it should end up feeding the LED modules. It’s the mental scaffold that makes subsequent steps both efficient and repeatable.

Visual inspection is the first line of defense, and it often reveals the fault without the need for more invasive tests. As you study the wiring harnesses, LED modules, and connectors, search for physical signs of distress: crushed insulation, frayed conductors, melted plastic, heat discoloration, or any flattening where wires pass through sharp openings or rubbing points. Pay special attention to areas where the harness curves near bulkhead edges, where weather seals compress, or where the chassis vibrates against a support bracket. An overzealous clamp or a misrouted loom can create a stress point that eventually wears insulation thin and encourages a short to ground or a high-impedance fault that mimics other symptoms. Look closely at connectors: a loose pin, a corroded contact, or a misaligned housing can introduce a path to ground or a sudden interruption in current. It’s also worth checking the solder joints on any custom wiring or DIY modules. Cold joints, cracked solder, or excessive solder that forms a bridge to adjacent pins can become a quiet short, especially under vibration. The LED bulbs themselves deserve a careful glance; even a small crack in the glass or a microfracture in the housing can alter current paths. In short, you’re hunting for little betrayals—micro-fissures, micro-frays, tiny gaps that only reveal themselves under pressure or heat.

Beyond the obvious, there are subtler patterns that can betray a fault. Chafing tends to occur where wires must flex during door operation, seat movement, or hood closure. Heat sources—engine manifolds, exhaust heat shields, or even high-energy drivers in compact LED modules—can bake insulation and harden plastics, making insulation brittle and more susceptible to wear. Moisture is another stealth factor; a small amount of condensate or rain splash near a poorly sealed connector can corrode contacts and create intermittent shorts that vanish when you disturb the circuit. Cold solder joints often look unremarkable but fail under load, forging intermittent connections that look like a voltage drop or a flicker rather than a persistent short. A practical tip is to gently shake or flex the loom near each connector; if an audible or visual change accompanies the movement, you’ve found a likely weak point. While visual inspection can uncover obvious problems, many shorts live inside the LED modules themselves or within the driver circuitry that powers them. In DIY or heavily modified installations, the demand on a driver board may exceed its original design tolerances, creating a path to ground that only shows up when the system is energized. In these cases, a careful balance of inspection and testing becomes essential.

When you’re ready to bring measurement into the equation, the multimeter becomes your most faithful ally. A practical approach begins with embracing the right test mode and respecting the circuit’s power state. For many technicians, the first instinct is to use the continuity mode: a mode typically marked by a diode symbol or a beep icon. With the fuse removed and the circuit de-energized, you can place one probe on the positive terminal of the removed fuse holder—the side that originally fed the power source—and the other probe on the negative terminal of that same fuse holder, which connects to the load and the rest of the harness. If the meter beeps, you have a direct short somewhere downstream of the fuse—the short is most likely in the wiring or within the LED module itself. The immediate implication is that you should stop testing further in that path until you isolate the component or wiring segment responsible. To do this with surgical precision, disconnect LED modules one at a time, or in small groups, from the main harness and repeat the continuity test on the fuse terminals after each disconnection. The moment the beep ceases, you’ve pinpointed the problematic module or run. Now you can inspect that segment more carefully, looking for pinched wires, damaged insulation, or a faulty connector that could be bridging to ground or to a live conductor.

Another essential dimension of the test is ruling out a ground fault. A common short arises when a live wire touches the metal chassis, creating a direct path to ground. To test for this, return to the continuity setup but shift one probe to a known good ground point on the car—examples include a robust bolt on the engine block, a clean frame rail, or a dedicated grounding point that you designate as a reference. If the meter beeps with the probe at the positive fuse terminal and the other probe at ground, you’ve verified a short to ground. In that case, you must trace the wiring from the fuse box through every connector and routing point, inspecting for insulation damage that might be touching metal. This route often reveals a previously unseen abrasion or a misrouted segment that rubs against the chassis on rough roads. It’s a moment that requires patience; the objective is not to rush but to map the entire path so you can address every vulnerable spot, from the fuse box to the LED module.

If the continuity and ground tests don’t reveal the short, the fault may lie inside the LED modules themselves or within the driver boards that regulate current to the diodes. In this scenario, a gentle physical check becomes valuable. Gently shake the LED bulb or module to listen for an intermittent contact or a loose internal component. A tiny movement might cause a momentary interruption that appears as a short under test conditions but behaves differently once you apply power. A closer look at solder joints inside the module can reveal cracks or signs of heat damage. A driver board with a marginal component can also create a condition that mimics a short under load, even though the module appears intact when tested in isolation. The bottom line is to respect the possibility that the problem is not purely external. A high-quality module with a robust driver should be the standard, but subpar or counterfeit parts can introduce hidden vulnerabilities that only become visible through careful testing and observation.

Once you’ve traced the fault to its origin—whether it’s a damaged wire, a bad connector, or a defective LED module—the repair path becomes practical. Replace the faulty component with a reliable, properly rated part. Reinstall the fuse and reconnect the battery, following the same safety sequence you started with. After re-energizing, perform a controlled test: power the system, observe the LEDs for a steady glow without flicker, and listen for any unusual sounds or heat buildup. If everything behaves as expected, you can proceed to reclose the connections, secure the loom with appropriate clamps and grommets, and ensure that all joints are protected from moisture and vibration. It’s wise to perform the final test in stages: first with the ignition off, then with the engine off and accessories engaged, and finally with the vehicle running at idle so you can observe under actual operating conditions. The goal is to confirm not only that the short is gone but that the surrounding system remains stable under real-world load.

Beyond repair, there is a preventive philosophy that should accompany every troubleshooting session. Good practice in wiring for LED modifications includes laying out a clean, unobtrusive routing that minimizes movement near sharp edges and heat sources. Use proper grommets where wires pass through metal panels, and employ strain relief where cables encounter frequent flex. It is also prudent to segregate power and signal lines from sensitive electronics to reduce noise and cross-talk, and to protect critical connections with weather-resistant seals where exposure to moisture is likely. When you install LED components, document their locations, the exact wire routes, and the fuse ratings used. Documentation is not merely bureaucratic; it is a practical map that makes future maintenance faster and safer. If you’ve done modifications in a car that has financing or a lease, also consider whether such changes affect warranties or insurance coverage. A careful installation that adheres to sound electrical principles tends to minimize dispute areas and supports long-term reliability, which is exactly what every car owner wants from a modification project.

Incorporating practical knowledge about installation and maintenance can help you prevent shorts before they arise. One actionable step is to align your wiring with the vehicle’s existing loom, rather than creating new, isolated bundles that require separate protective sleeves. When you route wires alongside existing conduits, you reduce the risk of rubbing and heat exposure while benefiting from the existing shields. If you opt for DIY connectors or aftermarket modules, test each segment for robustness before completing the full assembly. A robust practice is to test a new segment in isolation, ensuring it does not introduce a new path to ground or a new variable that affects other circuits. This mindset—of testing in small increments—helps you catch issues early and reduces the chance of cascading failures once the system is put back into service.

To connect this practical approach with broader guidance, there is a wealth of experience in the automotive community about how to install modifications safely and effectively. For instance, if you are seeking a broader discussion on the right way to integrate upgrades in a car while preserving reliability and resale value, you can refer to a comprehensive guide that centers on responsible modification practice and its implications. This contextual link emphasizes that a well-planned electrical upgrade should be as deliberate as the engineering behind the car’s original systems. In many ways, the discipline you apply to diagnosing a short becomes the discipline you apply to any modification project: plan, test, verify, and document.

As you complete this diagnostic journey, you may find it valuable to reflect on the broader ecosystem of modified vehicles. A thoughtful, safety-first approach to LED lighting not only prevents disasters like electrical fires or system failures but also preserves the long-term value and reliability of the vehicle. If this chapter has reinforced one overarching message, it is that a short is not an isolated anomaly; it is a symptom of how a modification interacts with a car’s established electrical architecture. When you treat each diagnostic step as a chance to learn about that interaction, you gain more than a temporary fix—you gain improved confidence and a foundation for smarter, safer upgrades. If you want to explore how to implement such upgrades with best practices, consider the general guidance on installation and modification practices available in related automotive resources. For example, see the guide linked here on the topic of installing car modifications safely and effectively: how to install modifications in a car.

For readers who want to extend their technical repertoire beyond the practical, a systematic, methodical approach to electrical faults in automotive systems is well documented in professional resources. An external, technically rigorous reference that aligns with the screenshots and diagrams you may see in your own troubleshooting session can provide deeper insights into short-circuit behavior, diagnostics, and test strategies. For a thorough, technical treatment of automotive short-finding methods, consult the detailed guidance at this external resource: How to find a short in an automotive harness.

In sum, the path to diagnosing and resolving a short in LED car modifications blends safety discipline, careful observation, and precise electrical testing. It rewards patience and a method that keeps power down until each step is validated. The strong takeaway is not just the fix for a single occurrence but a framework for approaching any future modification with confidence. When you marry the visual, tactile, and measurement-based clues, you create a reliable map of the system and a resilient installation that will stand up to the rigors of real-world driving. And if you want to anchor this practice in a broader sense of responsible modification, remember to consult reputable sources and reference materials that emphasize safety, legality, and long-term reliability. The objective is not merely to illuminate a problem but to illuminate a path to safer, smarter, and more durable car modifications.

Tracing the Short in LED Car Modifications: A Hands-On, Safety-First Journey Through Wiring, Modules, and Testing

When you work with LED car modifications, a short is more than an annoyance at the dash. It’s a fault that can heat wiring, wear connectors, or drain the battery in a heartbeat. The goal isn’t speed but accuracy: to find the fault, isolate it, and replace it with components that endure the vibrations, heat, and electrical noise of a moving vehicle. This chapter weaves a practical, methodical approach into a single, flowing narrative. It invites you into a process that respects safety, relies on trusted tools, and uses a logic that doesn’t rely on guesswork or hurried improvisation. The path to a cure begins with safety and ends with a tested, stable lighting system that behaves when the engine turns over and the switch sends power.

Safety is the backbone of every diagnostic, and it starts with a deliberate pause before any probing. Turn the vehicle off, and disconnect the battery. This simple act lowers the risk of electric shock, sparks, or unintended servo movements while you work. It also protects the rest of the electrical system from accidental shorts that could cascade into fuses blowing or modules failing. Once you’ve secured the power source, isolate the circuit you’re testing by removing the fuse associated with the affected LED run. The fuse acts as a protective choke point and, when pulled, prevents the circuit from feeding a potential fault downstream. This step is not merely precautionary; it’s a practical move that makes subsequent tests meaningful rather than dangerously speculative. As you progress, you’ll return to the fuse holder several times, but you’ll appreciate the clarity that a removed fuse provides when you test the circuit’s behavior with the power isolated.

With the power securely off and the fuse pulled, a careful visual inspection becomes the next compass. Look for obvious signs of damage that might have created a bridge between power and ground. Melted insulation, frayed conductors, scorched connectors, or burnt spots along the wire loom tell a stark story. Pay special attention to where wires bend, pass through grommets, or ride over sharp edges. The heat of the engine bay, vibrations from the suspension, and the friction of routing can slowly wear away insulation until a path appears between live and ground. A loose or corroded connector can also become a hotspot, producing intermittent shorts that only reveal themselves under load. A visually clean system isn’t a guarantee of faultlessness, but it’s a powerful first filter. If you notice abrasion at a point where the wire touches metal, or insulation that has softened and peeled away, that area deserves close scrutiny. Even a seemingly minor nick can become an entry point for a short when the system vibrates during a drive.

After the eyes come the tests, and the heart of this chapter rests on using a digital volt-ohm meter (DVM) to map where the circuit goes wrong. Start by turning the DVM to the resistance or ohms setting and ensure the power remains disconnected. The logic is straightforward: a very low resistance path between the positive supply rail and the negative or ground path signals a short. Place one probe on the positive terminal of the removed fuse holder—the side connected to the power source—and the other probe on the negative terminal of the same fuse holder, which ties into the load and wiring downstream. If the meter shows a near-zero resistance, a complete path exists somewhere in the portion of the circuit that would energize the LEDs when power is restored. That path is the culprit, whether it lives in the wiring harness, a connector, or inside an LED module itself. It’s tempting to test with the power on to watch a glow or a flicker; resist that impulse. Inaccurate readings—and further damage—can occur if the circuit is live during probing. A power-off test yields a truthful map of where current should not flow.

To narrow the fault, adopt a process of elimination. Disconnect LED modules one at a time—or in logical groups—from the main harness. With the power still off, repeat the resistance test at the fuse terminals after each disconnection. If the short disappears when a particular module or a set of wires is unplugged, you’ve located the section that creates the fault. This approach is more reliable than a broad, blind sweep of every wire; it lets you focus your attention on the suspect segment without disturbing the rest of the installation. As you perform these steps, you’ll often find that a damaged wire, a pinched connector, or a compromised LED driver board is the root cause. The key is to keep your testing disciplined and incremental, resisting the urge to replace multiple components at once—you risk chasing a ghost and wasting time.

Shorts in automotive wiring often hide in the ground path. A classic scenario is a live wire touching the car’s metal body, creating a direct path to ground that constantly saps power. To confirm this, use the same continuity test set to compromise but target the ground. Place one probe on the positive terminal of the fuse holder and the other on a known-good chassis ground point—a bolt on the engine block or a solid frame rail works well. If the meter beeps, you’ve found a ground short. The remedy then is a careful audit of the wire routing from the fuse box to the light modules, inspecting every connection point, grommet, and splice for damaged insulation or a grounded contact that could be energized in motion. This step often reveals a fault that was masquerading as a module issue, reminding you why a full-system view matters more than a single component focus.

If the short seems elusive after isolating sections, turn your attention to the LED modules themselves. A module can harbor an internal fault—a cracked solder joint, a fatigued driver board, or a loose internal connection—that only reveals itself when the unit is handling voltage and heat. Gently shake the LED bulb or module; some intermittent shorts show up as momentary disconnections or flickers that you can feel in the housing or hear as a faint clicking from inside the module. Inspect the solder joints inside the module with a careful eye for cracks or discoloration. A bad joint can look perfectly fine yet fail under load. The field of LED electronics often uses compact drivers and compact boards; when a joint or a driver sees repeated stress, its endurance erodes and a short can creep in under heat cycling. If you discover a questionable joint or a suspicious sign of heat damage, that module is a prime candidate for replacement.

With a suspect component identified, the next step is straightforward: replace the faulty part with a high-quality alternative and reassemble with care. Reconnect the circuit, reinstall the fuse of the correct rating, and restore the battery connection. Before you turn on the system, take a moment to double-check the routing and ensure there are no loose wires or pins sitting on hot surfaces. Power up and observe the circuit. If the LEDs illuminate normally and stay steady without dimming or flickering, you’ve closed the loop on a successful diagnosis. If the symptoms persist, you’ve got a new fault to chase—perhaps a second short that was masked by the first issue, or a hidden ground path you haven’t uncovered yet.

This chapter doesn’t exist in a vacuum. It sits within a larger conversation about how to approach modifications with craft rather than chance. As you explore this topic, you can consult resources that discuss the broader landscape of car modifications, safety, and maintenance. For instance, a concise guide like the Car Modifications Guide can provide a framework for planning wiring layouts, choosing compatible components, and documenting work to support future troubleshooting. Such a guide emphasizes method, not just outcome, and can be a steady companion as you build, test, and refine a lighting system that remains robust under real-world driving conditions. In practice, you’ll want to map your LED network with the same care you’d apply to any critical vehicle subsystem. The longer you work, the more you’ll appreciate how a disciplined diagnostic approach minimizes risk and maximizes reliability.

The diagnostic journey described here emphasizes a few core habits. First, work in a testable sequence: power down, isolate, inspect visually, test with a meter, and progressively narrow the suspect area. Second, guard against assumptions. A short can masquerade as a loose module, a bad connector, or a heat-damaged wire. Third, verify with purpose. When you replace a component, re-test the entire circuit to confirm there are no residual issues or cascading faults in the wiring harness. Finally, document your findings. A simple note next to the fuse diagram detailing which module or wire section caused the fault helps future maintenance and reduces the time needed if another issue appears down the road.

If you’re curious about broader guidance on troubleshooting electrical faults in automotive systems—including LED modifications—there are well-regarded reference materials that illustrate step-by-step procedures and diagrams. For readers who want a deeper dive beyond the practical steps described here, the linked external resource can provide a broader diagnostic mindset and a confirmation of best practices. In addition, the journey through this chapter is enriched by practical, real-world examples that show how the process unfolds when the stakes include safety, reliability, and the seamless operation of lighting that you rely on during night driving or adverse weather.

In the spirit of continuous learning and safe experimentation, you might also explore related guidance on modifications and their broader implications. For example, to learn more about how to approach car modifications with a balanced perspective, see the practical overview provided at the following resource: car-modifications-guide. This internal reference serves as a reminder that the technical task of locating a short sits within a larger discipline of responsible modification work. The diagnostic steps you’ve followed here—safety-first, methodical testing, and careful replacement—are universal across electrical faults, whether they appear in LED lighting runs or other electrical circuits in modern vehicles.

Ultimately, the short-finding process is as much about disciplined thinking as it is about using the right tools. A calm, methodical approach saves time, protects components, and keeps the vehicle ready for the road. When you’ve confirmed the fault and replaced the faulty part, run a thorough test beyond the moment of restoration. Turn the ignition to accessory, energize the LED circuit, and watch for any signs of stress—unusual warmth near a connector, a faint electrical scent, or an unexpected flicker. If everything behaves normally, you’ve earned a reliable, long-term solution that supports both the modification’s intended aesthetic and the vehicle’s overall electrical health.

For readers who want to explore a broader context of electrical diagnosis in cars, including how to approach other common faults beyond LED modifications, a trusted external resource offers detailed guidance and diagrams. This reference helps reinforce the concept that automotive electronics are a system, not a string of isolated parts. By adopting a systems-thinking mindset, you’ll be better prepared to maintain not only your LED installations but any future electrical work you undertake on a modified or stock vehicle.

In sum, locating a short in LED car modifications rests on a careful blend of safety, observation, and incremental testing. The approach described in this chapter—power down, isolate, inspect, test, eliminate, replace, and re-test—translates well beyond LEDs. It’s a reliable template for diagnosing electrical faults in any vehicle system, and it reflects the disciplined spirit that underpins quality car modification work. By applying these steps, you can restore reliability, preserve battery health, and keep the look and visibility of your LED modifications shining bright on every drive.

Final thoughts

Efficiency and safety are paramount when modifying your vehicle with LED lighting. Identifying and addressing shorts in your LED modifications not only enhances performance but also ensures the longevity of your components. By following this structured approach—from initial safety measures to comprehensive inspections and detailed testing—you empower yourself to tackle potential issues effectively. With diligence and the right tools, your car’s modifications will shine brightly and operate flawlessly.