Car modification offers a world of creativity and personalization, appealing to hobbyists, professionals, and enthusiasts alike. This journey begins with building a solid foundation in automotive fundamentals, understanding the core systems of a car, and acquiring hands-on skills essential for successful modifications. This article will guide you through four crucial chapters that cover everything from foundational knowledge to practical application, helping you navigate the intricate landscape of car modification. By engaging with this content, you’ll be well-equipped to embark on your own car modification adventure safely and successfully.

Laying the Groundwork: Building a Solid Foundation for Learning Car Modification

A car modification journey begins long before the first turn of a wrench. It starts with a clear mental map of how a car remains in balance when power, weight, and momentum collide on the road. To learn car modification effectively, you need a foundation that blends theory with practical sense, and that foundation must honor safety and legality just as strongly as curiosity and ambition. The core of this foundation lies in understanding the automotive heartbeat—the engine and powertrain—as well as the chassis, suspension, and electrical nerves that connect them. When you can read the language of horsepower, torque, and drivetrain interplay, you gain a compass for decisions that improve performance without inviting unreliability or danger. The engine, after all, is not a single widget but a system of parts that work in concert. Horsepower and torque measurements are more than numbers; they describe how the car responds to throttle input, how quickly it can accelerate, and how it maintains momentum through corners and climbs. Grasping how the engine relates to the transmission and driveline helps you anticipate how a modification might shift the balance of power. A deeper appreciation for the transmission type—manual or automatic—also matters. Manual gearboxes offer direct engagement and potential weight savings, but they require different tuning and maintenance considerations than automatics, which depend more on electronic control logic and small, precise adjustments to shift behavior. Understanding this interplay makes you a better planner for any modification, whether your goal is sharper acceleration, quicker responses in a corner, or improved fuel efficiency under steady cruising. The chassis and suspension form the stage on which that power acts. Suspension dynamics govern how the tire touches the road, how the car holds a line through a turn, and how it responds to bumps or weight transfer during hard acceleration or braking. Familiarity with shocks, struts, control arms, sway bars, and bushings helps you anticipate how changes to springs or dampers will alter handling and ride quality. This is not just about stiffer springs for speed; it’s about matching the whole system for a desired balance—ride comfort, tire contact patch, steering feel, and the ability to maintain grip in varying road conditions. The brakes, too, merit attention as a part of the feedback loop. Modifications that affect braking require an understanding of heat management, rotor and pad choices, and brake bias. A car can accelerate beautifully, but if it cannot decelerate with confidence, it quickly ceases to be enjoyable or safe. The fundamental safety net is the electrical system, the car’s nervous system. Reading wiring diagrams, understanding how fuses protect circuits, and recognizing how ECUs regulate everything from fuel delivery to ignition timing, ABS, and stability control, all empower you to modify with confidence. When you plan an upgrade, you should map where power comes from, how it travels, and where the protective devices reside. This knowledge helps prevent nuisance electrical gremlins or, worse, dangerous failures. Reading a diagram before you cut into a harness is a discipline that saves time and reduces risk, especially as you add components such as new lighting, audio, or sensors. With that foundation, you can begin layering hands-on skills that translate theory into workable results. Hands-on capability is not a luxury; it is a necessity for reliable learning in car modification. The first practical skill to anchor is metalwork and fabrication, starting with safe, approachable tasks and progressing to more intricate projects. MIG welding, for instance, is a practical entry point because it teaches you how metals join, how to control heat input, and how to manage distortion. Learning to measure, mark, and cut precisely underpins all fabrication work, whether you are crafting brackets for a new intercooler setup, fabricating a roll-cage for a track day, or trimming a panel to accommodate a larger wheel. Alongside welding and cutting, surface preparation and finishing are essential. Painting and finishing teach you about coatings, corrosion prevention, and the aesthetics that create professional results. The goal is not only a durable modification but also a visually polished one. Practice in a controlled environment with proper PPE, ventilation, and a plan for waste disposal. The ability to diagnose and tune a vehicle is equally crucial. Diagnostic tools, such as an OBD2 scanner, provide a window into how the engine and control modules respond under different conditions. You’ll learn to read codes, monitor live data, and interpret trends that reveal lean or rich mixtures, misfires, or sensor faults. Tuning, when done responsibly, can unlock performance gains while preserving reliability. It is a careful art that balances power, efficiency, and emissions, and it should be approached with a respect for safety margins and legality. The path you choose to learn—formal schooling, self-guided online study, apprenticeships, or hands-on workshops—should fit your goals, resources, and learning style. Formal automotive technology programs offer structured curricula, certified instructors, and access to specialized equipment. They seed the fundamentals in a systematic way and can accelerate your progression through more complex topics. Online courses and tutorials provide breadth and flexibility. They enable you to explore engine building, electronics, or tuning at your own pace, with countless hours of video demonstrations and interactive exercises. Apprenticeships and workshops place you inside real shops, where you soak up practical know-how from experienced technicians who have learned through years of troubleshooting and problem-solving on actual vehicles. Exposure to the daily realities of modification work is perhaps the most valuable education, because it teaches you to balance ambition with the constraints of time, budget, and safety. Community involvement cannot be underestimated. Online forums, social media groups, and local clubs connect you with people who have walked the same road. They are repositories of practical tips, troubleshooting strategies, and the hidden costs that do not appear in textbooks. The collective experience of enthusiasts can save you from repeating common mistakes and can provide encouragement that keeps you moving forward when a project stalls. As you accumulate knowledge, you will also become aware of the legal and safety boundaries that govern modifications. This is a non-negotiable aspect of learning to modify cars. Each region has its own rules about wheel sizes, exhaust noise, lighting, and color changes, and you must ensure your vehicle remains road-legal and compliant with inspections. Safety is the other constant. Wear PPE—gloves, eye protection, hearing protection—consistently. Work in a well-ventilated area, especially when welding or painting. Never modify critical safety systems, such as brakes or steering, without expert guidance. The road to responsible modification includes ongoing education. Attend car shows, track days, and industry expos to see what’s possible, what technologies are emerging, and what is feasible within your budget. Follow reputable automotive publications and technical blogs that offer analysis, not hype. Build relationships within the modification community; mentorship and peer feedback accelerate growth and keep you grounded in practical realities rather than speculative outcomes. Practical experience remains the bedrock of true mastery. Seek opportunities to work on donated or scrap vehicles, participate in community workshops, or apprentice at licensed shops. Hands-on practice translates classroom or online lessons into concrete capability. It teaches you to troubleshoot unexpected issues, manage your time, and develop a disciplined workflow. It also reinforces the importance of safety and legality. Throughout this journey, you must remain mindful of the broader ecosystem around car modification. The hobby sits at the intersection of engineering, artistry, and personal identity. It invites experimentation, but it also invites accountability— toward your own safety, toward other road users, and toward the long-term health of the vehicle. When you share your progress within a community or document your builds, you contribute to a collective knowledge base that helps others learn faster. This sense of shared purpose transforms individual effort into a broader culture of responsible, informed modification. A practical starting point is to ground your initial projects in non-invasive, exterior or interior upgrades that build confidence while minimizing risk. Upgrading exterior lighting, selecting new wheel designs, or applying tasteful body wraps offers tangible results without compromising core systems. These projects are valuable bridges between theory and practice. They introduce you to fitment considerations, electrical connections, and the ethics of aesthetics—so you learn not only how to do things, but how to do them well and with respect for other drivers on the road. For deeper theoretical grounding, invest time in established textbooks and curated online courses that cover electrical systems, mechanical principles, and the fundamentals of welding, cutting, and surface preparation. Take notes, solve practical problems, and simulate real-world scenarios. The purpose of study is to develop a blueprint for action—the kind of blueprint that prevents costly mistakes when you move to more ambitious builds. Industry engagement—through events like major auto shows or local expos—offers exposure to cutting-edge technology, emerging trends, and the chance to network with seasoned professionals who can mentor you or collaborate on projects. The social dimension of learning matters because car modification is often a collaborative craft. The practical experience side, meanwhile, anchors your formal and informal education. When you work on real vehicles—whether donated, scrapped, or on lease to a reputable shop—you encounter the unpredictable, the time constraints, and the realities of budget limits. You learn to evaluate which modifications are worth pursuing, how to sequence them, and how to manage risk when a modification might affect reliability or warranty. Community engagement completes the loop. If you participate in online communities or local clubs, you gain a feedback-rich environment that helps you improve faster and stay motivated. You learn from others’ successes and failures, and you contribute by sharing your own experiences. This reciprocal exchange accelerates learning and keeps you connected to the evolving language of car culture. The culmination of a strong foundation is not a single project but a mindset: a disciplined blend of curiosity, safety, legality, and practical problem-solving. As you progress, you will begin to see relationships between what you study and what you do with your hands. You will understand why certain exhaust choices may alter backpressure, why wheel fitment affects suspension geometry, and why a simple wiring change can ripple into diagnostic codes if not planned correctly. The journey is iterative, not linear. Each project teaches you more about your goals, your limits, and the kind of car you want to build. In this sense, a good foundation is less about reaching a particular outcome and more about building a sustainable approach to learning. Along the way, you may encounter moments when you question whether the path you chose is the right one. When that happens, revisit your core questions: Do you understand the engine, the drivetrain, the suspension, and the wiring enough to plan and execute a modification safely? Are you respecting local laws and ensuring the vehicle remains road-legal? Do you have access to the right tools, the right mentorship, and the right communities to support your growth? If you can answer yes to those questions, you are reinforcing the foundation that will carry you through more complex builds and longer-term goals. Finally, a note on internal and external resources that can smooth the road ahead. An internal resource that can be especially helpful is a practical guide to DIY car modifications that you can reference as you begin. A good starting point is a DIY car modification guide that walks you through the basics of installation, fitment, and safety. This kind of resource helps you translate theory into repeatable practice, keeping your early projects grounded in proven methods. For readers who want to continue expanding their horizons, an external resource such as a respected industry association or trade show page provides insights beyond the garage and into how the field is evolving. In addition, you can consult a broad range of educational materials that discuss the ethics, resale considerations, and insurance implications of modified cars. These perspectives remind you that every modification carries consequences beyond appearance or raw performance. To keep the journey anchored, remember that learning car modification is a long arc that rewards patience, meticulous planning, and relentless practice. The most successful modifiers treat knowledge as a living toolkit—one that grows with every project, every mistake, and every conversation with a mentor or a peer. With a sturdy foundation in fundamentals, a pathway that matches your goals, and a commitment to safety and legality, you can turn curiosity into craft, and craft into responsible, rewarding learning that continues long after the first bolt is tightened. For readers who want to deepen their exploration of practical methods and community-driven learning, see the DIY car modification guide linked here for a hands-on starting point: DIY car modification guide. The road ahead rewards disciplined learning, steady practice, and thoughtful engagement with a broader community of enthusiasts. As you transition from foundational theory to progressive hands-on projects, you’ll begin to recognize that every modification is as much about understanding the car as it is about shaping your own capability. External resources can broaden your perspective, and staying connected to a vibrant community ensures your learning remains dynamic and grounded. For ongoing reading and guidance, consider diverse perspectives and up-to-date information available through industry channels and educational outlets. External resource: https://www.sema.org/

Hands-On Mastery: Turning Theory into Real-World Car Modifications

When you learn to modify cars, theory is the map and hands-on practice is the journey that fills in the terrain. The most transformative progress comes not from reading about parts or watching demonstrations alone, but from repeatedly applying what you’ve learned under real-world constraints. This chapter follows a single through-line: build a steady ladder of skills that begins with safe, simple tasks and culminates in precise fabrication, robust tuning, and professional finishing. The goal is not to rush into dramatic changes but to cultivate a practiced sense for how components interact, how tools behave, and how your choices affect safety, legality, and long-term performance. In practice, mastery emerges when your daily sessions blend deliberate planning, careful measurement, and disciplined reflection as you move from small wins to more ambitious projects.

The core hands-on skills—welding, cutting, grinding, and painting—are not abstract techniques. They are craft practices that demand patience, tool literacy, and a safety-first mindset. For beginners, welding starts as a curiosity about how metal becomes connected. MIG welding, as a friendly entry point, teaches you control, heat management, and puddle discipline. Yet even this seemingly straightforward process hides a host of subtleties: choosing the right wire feed, setting the proper voltage, ensuring clean ground, and avoiding burn-through. The first wins often come from joining two sheets for a mock-up bracket or fabricating a small gusset that reinforces a non-structural piece. These early projects provide immediate, tangible feedback and build your confidence without risking critical systems.

Cutting and grinding demand equal parts precision and restraint. A steady hand and a calm workspace help you control heat input, maintain clean edges, and prevent warping. Practice on scrap metal before touching any component that bears load or carries vital fluids. You’ll learn to choose the right abrasive, how to dress a wheel properly, and how to manage heat-affected zones. Mastery isn’t in speed but in the ability to reproduce a clean cut, a smooth grind, and a consistently dressed edge that will weld or mate cleanly with the next piece. In the same way, painting and finishing are less about color selection and more about surface preparation, substrate compatibility, and the sequence of steps that yield a durable, showroom-quality surface. The difference between a good finish and a great finish is often a few well-timed passes with a guide coat, a careful wet-sand routine, and a controlled environment that minimizes dust.

Throughout this process, the value of plans, measurements, and checks cannot be overstated. Before you ever pick up a tool, define the goal, the constraints, and the tolerances. This begins with a clear sketch or CAD-inspired mock-up that translates your vision into a sequence of actions. Then, create a checklist for the task: material type, thickness, weld type, heat management strategy, protective coatings, and inspection criteria. A disciplined approach turns a messy afternoon into a productive session with repeatable results. It also reduces the risk of costly mistakes. When you document your steps, you gain a personal knowledge base that grows with each project. You start to see patterns—what works reliably, what needs extra clamps, where heat sensitivity becomes a governing factor—patterns that guide future builds and save time.

The path from simple tasks to more complex modifications mirrors the arc of any skilled craft. You begin with exterior tweaks that yield visible, quick wins: new lighting assemblies, wheel and tire changes that improve grip and stance, decals or wraps that personalize the silhouette, or a tasteful interior audio upgrade. These projects are deliberately chosen for their lower risk and fast, tangible payoff. They also offer a concrete arena to practice tool control, surface prep, and alignment checks. As your comfort grows, you can escalate to more demanding tasks: custom brackets for nonstandard components, light chassis modifications that require precise measurement, or more intricate paint and finishing jobs that demand consistent film thickness and curing conditions.

A crucial part of growing competence is recognizing your learning path. There is no universal route to mastery, but there is a reliable rhythm: study, practice, reflect, repeat. Formal training remains the most efficient way to compress time, because structured programs provide foundational theory, practiced demonstrations, and measured feedback under supervision. Vocational schools and accredited workshops aren’t just about learning tools; they cultivate a mindset of safety, quality control, and accountability that trenches into all future work. For those pursuing a DIY or self-guided route, online courses and a steady stream of instructional videos can supplement hands-on practice. Platforms host step-by-step tutorials, and while the quality varies, a curated selection from reputable instructors can illuminate best practices, setup tips, and common mistakes. In either path, the emphasis is on progressing through a ladder of challenges rather than leaping to a grand, high-risk modification without foundation.

When you consider the actual practice of modification, the question of safety optimization should frame every decision. Work in a well-ventilated space, use proper PPE, and keep a clean, organized shop that minimizes tripping hazards and improves accuracy. A dedicated welder’s mask, heat-resistant gloves, and flame-retardant clothing become second nature once you’ve felt the sting of hot metal and the risk of sparks. The same careful attention applies to chemical coatings, solvents, and cleaning agents used in paint and finishing. Ventilation matters not only for comfort but also for health and product quality. Gas or oil-fed heat sources introduce hazards that must be anticipated with proper extinguishing media, fire blankets, and a clear exit path. These are not optional extras; they are essential elements of reliable workmanship and long-term safety. Your workspace should also reflect thoughtful zoning: a design zone for cutting and welding, a finishing zone for painting and sealing, and a testing zone for diagnostic checks and adjustments. Over time, the organization of your shop becomes part of your skill set because it directly affects repeatability, quality, and safety.

A practical rookie-friendly strategy is to start with non-structural, reversible, or cosmetic tasks that still demand diagnostic thinking and careful technique. Installing aftermarket wheel setups teaches you critical alignment considerations, torque sequencing, and the interplay between unsprung mass and handling, without compromising essential safety features. Upgrading lighting systems challenges your understanding of electrical circuits, fusing, and voltage compatibility, while still keeping the modifications temporary and removable. Applying a body wrap or a decal kit tests your surface preparation and masking discipline, with visible results that reinforce your commitment to quality work. For interior upgrades, a new audio or infotainment interface can be a meaningful project that hones wiring diagrams literacy, connector matching, and secure mounting—without introducing risks to critical systems.

As your confidence grows, you’ll encounter two kinds of knowledge that define mastery. The first is technical fluency—the ability to select the right tool, set correct parameters, and predict how a material will respond to a given process. The second is project fluency—the capacity to plan a sequence of steps, anticipate bottlenecks, and adapt when a part doesn’t fit as expected. Both require practice, but project fluency also relies on critical feedback loops. When something doesn’t fit, you pause, analyze, and adjust rather than forcing the issue. This is where steady documentation pays dividends. A simple project journal that records dimensions, materials, tool settings, and outcomes turns trial-and-error into data you can reference for future builds. It is not about perfection on the first attempt; it is about creating a track record that shows your incremental improvement and helps you avoid repeating mistakes.

The chapter on hands-on skills would be incomplete without acknowledging the role of community and mentorship. Learning alongside peers accelerates progress. Demonstrations by experienced modifiers reveal nuances you might not glean from videos or textbooks. Constructive critique helps you see what you cannot perceive on your own, such as subtle misalignments, heat-induced distortions, or edge preparation that affects weld quality. Online communities and local workshops provide a continuous feedback loop, exposing you to a variety of approaches and styles while keeping you tethered to shared safety standards and legal considerations. If you are curious about a DIY approach, engaging with a community and reviewing a practical guide like Do-It- Yourself Car Modifications can offer real-world perspectives and troubleshooting strategies that you can apply in your own projects.

The progression from beginner experimentation to steady competence is not a straight line, but it is a repeatable pattern. Start with a clear objective, assemble the necessary tools and materials, set up a safe workspace, and plan a sequence of steps that minimize risk. Execute with deliberate care, test incrementally, and document outcomes. When you reach a milestone, celebrate the result, but also extract the lessons. What would you do differently next time? How could you improve the finish or the dimensional accuracy? This reflective habit prevents stagnation and transforms practice into a development loop that continuously raises your standards.

Finally, embrace the reality that car modification happens within a broader ecosystem of safety, legality, and responsibility. The most successful hobbyists and professionals balance creativity with respect for the car’s engineering integrity and the laws that govern road-going vehicles. A solid mastery rests on four pillars: theoretical literacy, hands-on discipline, safety-conscious practice, and ongoing engagement with mentors and peers. When you internalize this trio of knowledge and skill, you don’t merely imitate what others have done; you begin to execute modifications that are technically sound, aesthetically satisfying, and compliant with local regulations. This is how you translate curiosity into craftsmanship and curiosity into a credible, durable skill set that will serve you for years to come.

For readers who want a practical starting point on the DIY track, explore Do-It- Yourself Car Modifications as a resource for structured, hands-on guidance that can complement your formal training or online courses. Do-It- Yourself Car Modifications

External resource: https://www.youtube.com/watch?v=7v6RlH9rWuI

Charting Your Learning Path for Car Modification: From Aesthetic Craft to Engineering Mastery

Choosing a learning path in car modification is less about chasing a single blueprint and more about aligning your curiosity with a sustainable practice. The journey starts by naming your end goal in a way that can adapt as your interests grow. Do you want to sculpt a car’s appearance into a personal statement, or are you drawn to the engineering challenge behind performance, reliability, and future technologies? Either route can be deeply rewarding, but the path you choose should fit how you learn, where you want to go, and how you plan to stay safe, legal, and effective as you practice. In this sense, learning car modification isn’t a one-time decision but a living map. It invites you to blend theory with practice, to test ideas in simulated or controlled real-world environments, and to keep pace with a field that keeps evolving as new technologies emerge and regulatory landscapes shift. As you begin, you’ll quickly realize that the quality of your choices today shapes the pace and resilience of your growth tomorrow. A thoughtful approach to learning helps you avoid dead ends and keeps you moving toward meaningful, durable skills rather than short-lived tricks that may fade in importance or legality.

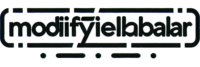

The most fundamental distinction in choosing a learning path lies in motive and scale. If your primary aim is aesthetic expression—paint colors, wraps, decals, body lines, grille shapes, and wheel choices—you can devote substantial attention to the visual and tactile aspects of a car, recognizing that the impact of these decisions is most immediate and gratifying. This path rewards an eye for proportion, color theory, lighting, and surface finishes. It also invites you to collaborate with specialists or to learn specific crafts that translate well to appearance-focused work, such as bodywork, painting, and upholstery to achieve a professional look. Importantly, a purely cosmetic route does not require you to master the core mechanical systems in depth, though a healthy respect for those systems remains essential to avoid compromising safety or legality. In other words, you can begin with surface-level transformations while building a foundational understanding of how the vehicle operates so your cosmetic choices do not conflict with performance or safety requirements. If your heart pulls toward style, you’ll often find motivation in communities that celebrate design, not just function, and you’ll learn to balance bold choices with a sense of restraint that preserves durability and road legitimacy.

On the other hand, a path oriented toward engineering and performance invites a deeper dive into the car’s inner workings. Here the study expands from how a feature looks to how it behaves under load, at speed, and across varying temperatures and road conditions. You’ll explore how the engine breathes, what changes in the exhaust tune, how the suspension translates steering input into wheels’ response, and how electrical systems coordinate with sensors to deliver reliability. This orientation naturally leads to more rigorous training in core automotive disciplines, materials science, dynamics, and control concepts. If you choose this route, you’ll eventually encounter questions about drivability, efficiency, safety margins, and regulatory compliance with the same seriousness you bring to performance gains. You’ll want to cultivate a habit of incremental testing, cautious experimentation, and thorough documentation because even small changes can have cascading effects on behavior, comfort, and legality.

The literature on adult learning in technical domains supports a blended approach: theory matters, but it only matters if you can translate it into practical capability. With car modification, that translation happens through hands-on practice, careful measurement, and disciplined reflection. The theory you encounter—whether it’s about engine dynamics, chassis tuning, or control systems—needs a workspace where you can test ideas, observe outcomes, and learn from mistakes without risking your safety, your vehicle, or others on the road. This is where the balance between formal education, structured online learning, apprenticeships, and community-based learning becomes crucial. A formal program can provide a structured backbone—systematic curricula, vetted instructors, and access to specialized equipment. An online or hybrid route can offer breadth and flexibility, enabling you to tailor content to your interests and pace. Apprenticeships and shop-based work place you in real-world environments where skilled mentors translate abstract concepts into practical skill under the watchful eye of industry practice. Communities and forums offer a social ecosystem where questions are answered, experiences are shared, and trends are identified through collective intelligence. The trick lies in designing a path that leverages the strengths of each modality while compensating for their weaknesses.

Approaching the decision with foresight also means acknowledging the prerequisites for more advanced ambitions. If you’re contemplating topics like performance tuning, autonomous vehicle integration, or high-level control systems, you should prepare for a broader mathematical and computational foundation. The arc from bolt-on aesthetics to autonomous systems is steep, but it is navigable with a clear plan. A comprehensive online course focusing on autonomous vehicles points to the kinds of disciplines that become relevant at the higher end of the spectrum: linear algebra, calculus, probability theory, and modeling in kinematics and dynamics. It also suggests that familiarity with computer vision, artificial intelligence, or robotics, while not strictly mandatory at the outset, can significantly accelerate progress when you pursue cutting-edge automotive projects. The logic here isn’t to transform you into a researcher overnight, but to signal that the deeper you go, the more you rely on mathematical thinking, simulation, and cross-disciplinary knowledge. Starting with a foundational module that surveys both hardware and software components of autonomous systems can give you a framework for later specialization, risk assessment, and decision-making in engineering projects.

Simulation emerges as a powerful bridge between theory and practice, especially for those who want to experiment with advanced concepts in a safe, controlled environment. Platforms that offer realistic physics and sensor modeling enable you to test localization, object detection, motion planning, and vehicle control without the hazards of real-world testing. This allows you to iteratively refine algorithms, compare alternatives, and understand how design choices ripple through an entire system. For people who enjoy seeing ideas come to life quickly, simulations reduce the friction of moving from concept to validated practice. They also provide a common ground where novices and veterans can discuss results, share insights, and challenge assumptions with objective data. The ability to simulate scenarios such as varying traffic conditions, sensor noise, and weather effects helps you develop resilience in your approach, so you can carry that discipline into physical projects when the time comes.

If your aim leans toward aesthetics and personal expression, you can still benefit from this broader framework. There is a healthy overlap between visual customization and engineering principles. For example, understanding weight distribution and aerodynamics can inform lightweight, visually appealing bodywork that also preserves handling and efficiency. You don’t need to master every calculation to enjoy meaningful progress, but developing a working intuition about how changes in appearance interact with performance can prevent missteps that undermine both safety and appeal. In this light, the learning path should be treated as a spectrum rather than a binary choice: you can begin by exploring visual customization while gradually weaving in core mechanical concepts that help you make informed decisions about compatibility and durability. This approach keeps your curiosity alive and your projects sustainable.

Whichever route you choose, practical experience remains essential. Start with small, low-risk projects that reinforce safe practices and build confidence. Exterior modifications like subtle wheel choices, finishes, decals, or lighting upgrades can be excellent first steps that teach you about alignment, electrical considerations, and regulatory limits without requiring major structural changes. Interior upgrades—such as audio systems and lighting—offer a similar entry point, providing hands-on practice with wiring, power management, and ergonomics. For those who are drawn to performance basics, simple tasks such as air filter maintenance or exhaust enhancements can introduce you to the concept of system integration and feedback, while reminding you to verify compatibility and compliance with local laws. Across all paths, the emphasis should be on learning how to learn: how to plan, how to measure results, how to iterate, and how to document what you discover so you can build on it rather than repeating mistakes.

As you design your path, you should also map the unseen costs and commitments. Safety and legality aren’t optional add-ons; they are foundational to sustainable practice. PPE—gloves, eye protection, hearing protection—must become second nature. Workspaces should be ventilated and organized, with a mindset that treats modifications with the same care you would give to any mechanical system you rely on daily. In parallel, you should research the regulations that apply where you live. Wheel sizes, noise levels, lighting requirements, and emissions standards can all influence what you can do legally. A well-framed plan accounts for these realities, ensuring that your creativity remains within permissible boundaries and that your vehicle can pass inspections when required. If you proceed without this awareness, your enthusiasm can give way to costly backtracking or even legal risk. Treat the journey as a long-term commitment to safe, legal, and responsible practice that respects the vehicle as a machine with many interconnected parts.

Community and mentorship often determine how smoothly your path unfolds. Engaging with fellow enthusiasts who share your tendencies can accelerate learning, reveal common pitfalls, and provide practical tips that only experience yields. The value of a learning network grows as your projects become more ambitious. A sense of belonging helps you stay motivated during difficult weeks and gives you a steady stream of feedback about aesthetics, performance, and reliability. Your learning map should therefore include opportunities to observe and contribute to real-world work, whether through informal shop visits, sanctioned workshops, or structured apprenticeship arrangements. While formal credentials can help in some contexts, the most valuable gains frequently come from hands-on practice in a supportive environment, where questions are welcomed and guidance is available.

As you refine your plan, remember to keep your long-term interests at the center. Treat learning as continuous refinement rather than a full overhaul. Your previous experiences—whether from formal coursework, personal tinkering, or related technical hobbies—are valuable assets to be leveraged as you expand into new areas. The strength of your path lies in its adaptability: you should feel free to pause and pivot toward a different emphasis if your passions shift, all while maintaining a solid foundation that keeps you safe, productive, and compliant. This balanced perspective helps prevent burnout and ensures you remain engaged over the years, turning curiosity into competence and, eventually, into a meaningful practice that can endure changes in technology, regulations, and personal goals.

Ultimately, the act of choosing your learning path in car modification is about creating a coherent, resilient framework that serves your ambitions. It invites you to blend analysis with hands-on work, theory with practice, aesthetics with engineering, and personal expression with social responsibility. You can pursue a path that emphasizes creative design while gradually incorporating the science of performance. Or you can dive into the engineering side from the outset, building a robust toolkit that enables sophisticated, data-driven experimentation. Either way, the chapters you write today will become the foundation for the projects you dream up tomorrow. To support that growth, consider the practical steps that many learners find effective: start with a clear vision, assemble a learning mix that suits your pace, increase complexity gradually, and continuously test ideas in safe contexts. Document what you learn, seek feedback from trusted mentors, and stay connected to a community that shares your standards for safety and legality. In doing so, you’ll cultivate a durable capability that not only elevates your craft but also keeps you curious, confident, and responsible as you explore the vast world of car modification.

For readers weighing the legal and practical implications of moving forward, a helpful reminder is to consider how modifications affect broader commitments, such as insurance and resale value. A well-informed approach recognizes that cosmetic changes can carry different implications than performance upgrades, and that some modifications may influence coverage or premiums. This awareness helps ensure that your path remains aligned with your financial and personal goals while you pursue your craft. What Modifications Affect Car Insurance offers a starting point for understanding these dynamics, reinforcing the idea that learning about car modification is not only about making things look or perform a certain way but also about anticipating how changes ripple through your ownership experience. As you commit to a path, you’ll appreciate how this broader perspective supports responsible exploration and durable, satisfying outcomes.

In the end, your learning path should feel like a custom blueprint rather than a rigid syllabus. It should invite curiosity, accommodate your life schedule, and respect safety and legality as core principles. If you view your journey as a continuous refinement, you’ll find that today’s curiosity can become tomorrow’s competence, and that every project—whether focused on style, function, or both—moves you closer to mastery. The road to car modification is not a one-size-fits-all highway. It’s a terrain you map with your own goals, your own pace, and your own standards for responsible practice. The chapters you build along the way will reflect your evolving interests and the thoughtful choices you make now will empower you to pursue more ambitious ideas with confidence and care.

External resource: https://www.coursera.org/learn/autonomous-vehicles

Starting Small, Building Skill: A Practice-Driven Roadmap to Learn Car Modification

Learning car modification is a journey that rewards patience as much as ambition. The most reliable way to move from curiosity to competence is to begin with small, manageable tasks and let each success build the confidence and the knowledge needed for more ambitious projects. This approach is not merely about avoiding mistakes; it’s about shaping a deep, practical understanding of how a car’s systems interact and how your interventions ripple through performance, safety, and legality. When you frame learning as a repeated, thoughtful practice, you create a resilient foundation that supports intelligent experimentation, responsible risk-taking, and sustained progress over time. The road from a first modification to a more complex build is less a sprint and more a careful climb, with each modest retrofit acting as a stepping stone toward a broader, more capable skill set.

Begin with the most accessible, non-critical save for the basics of confidence-building and system literacy. Exterior lighting upgrades, wheel and tire changes, and simple cosmetic touches offer immediate feedback without threatening the core mechanical or safety-critical systems. Installing LED headlights, for example, introduces you to electrical connectors, bulb types, and the importance of correct polarity and secure mounting. It’s a gentle introduction to the language of circuits, fuses, and harness routing. Upgrading wheels and tires expands your understanding of bolt patterns, offset, clearance, and the delicate balance between aesthetics and function. Decals and wraps teach alignment, finish prep, and the discipline of preparation—lessons easily transferable to more involved projects. Each small project yields tangible results and, crucially, reveals the limits of your current toolkit and knowledge, guiding your next steps with honesty.

The power of practice is twofold. First, it reinforces manual fluency with tools and fastidious workmanship. You learn to tighten bolts to spec, to read torque values reliably, and to appreciate fitment margins—the difference between a snug installation and a problem that compounds later. Second, practice cultivates a robust mental model of how a car is put together. When you replace a headlight, you confront electrical connectors, bulb types, and the interplay between electrical and mechanical fit. When you select new wheels, you confront bolt patterns, offsets, and tire measurements that affect steering feel and ride quality. These discrete lessons accumulate into a practical intuition that makes you more capable with each new project, reducing the risk of costly mistakes and unsafe outcomes.

A practical path forward begins with simple, well-scoped projects performed in a controlled environment. Start with non-critical systems first, and choose tasks that allow you to observe cause and effect directly. Document your process as you go: note the parts selected, the steps you followed, any challenges you encountered, and how you resolved them. A written record becomes a personal reference library, a way to track what worked, what didn’t, and why. This habit pays dividends when you later attempt more complex modifications, because you won’t be starting from scratch every time. The act of documenting also deepens your learning by externalizing your tacit knowledge—the kind of understanding that often stays in your hands until you articulate it clearly.

To stay on a constructive trajectory, couple your practice with deliberate progression. After you’re comfortable with cosmetic or non-critical upgrades, move to slightly more involved tasks that still avoid altering essential systems. For example, you might experiment with a performance exhaust tip installation or a more sophisticated interior lighting setup that requires basic wiring and routing. Each step increases your cognitive load in a measured way while remaining within the safe boundaries of your emerging skill set. As you broaden your scope, you’ll begin to anticipate how changes to one area can influence another. A new exhaust tone might demand adjustments in mounting points or vibration isolation. A different wheel choice could affect suspension dynamics and acceleration feel. The goal isn’t to chase novelty for its own sake but to cultivate an integrated understanding of how modifications interact with the car’s broader architecture.

This intentional pacing dovetails with a strong emphasis on safety and legality. Practice becomes meaningful only if it remains anchored in responsible behavior. You should consistently wear appropriate PPE—gloves, eye protection, and hearing protection as appropriate—and work in a well-ventilated space when you’re dealing with solvents, paints, or welding fumes. When you begin any project, pause to assess the potential impacts on critical safety systems. Modifying brakes, steering geometry, or traction control without expert guidance is not a risk worth taking, and it’s wise to reserve those tasks for formal training or supervised work. Beyond safety, you must also consider legality. Local and national regulations regulate wheel sizes, exhaust noise, lighting colors, and other appearance-related modifications. Before you commit to a project, verify that your plan can pass inspection and remain road-legal. This legal mindfulness becomes second nature as you gain experience, turning a hobby into a responsible, durable practice rather than a reckless or impulsive activity.

Developing a reliable practice loop is essential. Start with a plan that defines the objective, the tools you’ll need, and a rough timeline. Gather the necessary parts and PPE in advance, ensuring compatibility with your vehicle and any existing systems. Then execute the work in incremental steps, pausing to test and inspect after each stage. After you complete a modification, reflect on what went well and what could be improved. Was the part fitment precise? Did you observe any unintended consequences, such as wiring strain, heat buildup, or vibration? If so, how could you adjust future approaches to avoid repeating the same issues? This reflective habit converts each project into a learning opportunity rather than a one-off task and steadily enhances your competence.

An essential part of this progression is choosing trusted learning sources while cultivating discernment. The car modification landscape is rich with tutorials and guides, ranging from comprehensive courses to quick tips. It’s important to critically assess the quality of information you follow. Prioritize sources that emphasize safety, step-by-step guidance, and thorough explanations of why certain methods work. When you encounter conflicting advice, compare the underlying principles and tests behind each approach. This critical literacy becomes a tool you carry across all projects, allowing you to weigh risks, costs, and benefits as you plan more ambitious work.

To reinforce the practical nature of learning, integrate hands-on practice with structured study. Theoretical understanding—the why behind a torque spec, the function of an ECU, or the role of a suspension component—gives you direction, but only hands-on work confirms it. Use diagnostic tools judiciously as you grow: an OBD-II reader or similar device can reveal how a system responds to modifications, but you should interpret the data with an eye toward how changes might affect reliability and safety. The aim is not to turn you into a master technician overnight but to develop a disciplined curiosity: to ask the right questions, test hypotheses safely, and build a coherent picture of how your vehicle works and how your modifications alter its behavior.

As you accumulate small, successful projects, your confidence will have a tangible, positive effect on your decisions. You’ll feel more comfortable planning higher-stakes tasks such as engine-tuning, suspension upgrades, or more advanced electronic installations. Yet this comfort comes only after you’ve established the indicators of readiness: clear and reproducible results from careful measurements, disciplined adherence to torque specifications and fastener selection, and a growing ability to foresee how a modification will affect other subsystems. The incremental approach keeps you from being overwhelmed while still offering a clear path toward more meaningful performance gains.

For a practical, step-by-step view of starting with do-it-yourself projects, a concise guide on do-it-yourself car modifications offers a helpful starting point. do-it-yourself car modifications complements the mindset described here by presenting a catalog of approachable projects, the common pitfalls, and the discipline required to stay aligned with safety and regulatory considerations. This resource is not a substitute for hands-on practice or formal training, but it can serve as a useful orientation to the kinds of tasks that beginners typically encounter and the learning rhythm that best supports long-term growth. Remember, the value of any guide lies not in the novelty of the idea but in how clearly it communicates the procedural steps, safety checks, and rationale behind each move.

As you plan your next projects, keep your eyes on the horizon but stay rooted in the present. The path from a first, small modification to a robust, capable build is built one careful step at a time. Each completed task teaches you something new about fit, function, and the delicate balance between aesthetics and performance. In the end, you’ll not only enjoy the satisfaction of a job well done; you’ll have cultivated a practical competence that makes every future project more informed, safer, and more enjoyable. That is the essence of learning car modification through starting small and practicing with intention.

External resource: https://www.youtube.com/watch?v=6cKxX0LqVUo

Final thoughts

As you embark on your journey toward mastering car modification, remember that success hinges on a strong foundation of knowledge, hands-on skills, and a commitment to safety and legality. Whether you are a hobbyist seeking personal expression, a professional tuner aiming for performance optimization, or an enthusiast dedicated to classic car restoration, the principles outlined in this article will serve you well. Continually engage with the community, stay informed, and don’t hesitate to seek out new knowledge and experiences. The world of car modification awaits your creative touch.