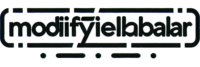

Entering the world of car modification is more than just a dream for automotive enthusiasts; it’s a powerful opportunity to turn passion into profit. With the rising number of hobbyists and professionals dedicated to enhancing vehicle aesthetics and performance, a car modification shop can meet a robust demand while celebrating the art of personalizing rides. This comprehensive guide provides a roadmap for launching your shop from market research to building a skilled team. Each chapter delves into critical components that will help you understand and navigate the complexities of the automotive modification business, ensuring you lay a solid foundation for success.

From Insight to Asphalt: Market Research and a Durable Plan for Launching Your Car Modification Shop

Market research is the compass that guides every successful car modification shop from its first spark to steady, long-term operation. It translates a dream of automotive craft into a viable business by revealing who will pay for your expertise, what they want, and how to position your offerings so you stand out in a crowded field. When you begin with data, not guesses, you build a roadmap that aligns the shop’s capabilities with real-world demand, defines a precise service mix, and shapes a budget that survives shifting market currents. This chapter weaves together the essential threads of market intelligence and planning, showing how findings translate into concrete decisions about customers, location, services, pricing, and growth over the first critical years.

Begin with the lay of the land. Look beyond the shiny photos of customized cars and ask practical questions: how many vehicles are on the street in your chosen area, what varieties of owners cluster there, and what they’re willing to invest for performance, aesthetics, or reliability. Data gathering can be straightforward and inexpensive. Start with public vehicle registration counts, traffic patterns, and nearby complementary businesses—performance shops, detailing studios, body shops, and parts retailers. Then layer in the human perspective: surveys, casual conversations with local enthusiasts, and online forums where opinions about modifications, quality, and service expectations circulate. This is where you uncover priorities that will define your niche. A shop might find a steady stream of customers seeking high-end performance work, or you may discover a more resilient demand for appearance-oriented upgrades that showcase craftsmanship and personal branding. Either path is legitimate, but the choice must be grounded in what the market actually sustains, not what you wish it would.

Competitor analysis follows naturally from market reconnaissance. Map the nearby landscape of automotive service providers—what they offer, how they price, and what customers say about them in reviews. Pay attention to gaps in their portfolios. Do rivals focus on rapid, entry-level upgrades but neglect meticulous, long-haul builds? Do they excel at aesthetics but lag in drivability or reliability post-install? Your aim is to identify a clear market position that leverages your strengths while addressing a need others overlook. A well-chosen niche—whether it is high-performance tuning for enthusiasts, eco-friendly and efficiency-focused mods, or premium customization and show-car finishes—creates a defensible space where marketing messages can resonate and pricing can reflect value rather than sheer volume.

All this data becomes the backbone of a detailed business plan. A plan isn’t a sterile document; it’s a living blueprint that translates insights into numbers, processes, and milestones. Start with financial projections that consider startup costs and the runway required to reach cash flow break-even. The spectrum of startup budgets in this field is wide: a modest, small-shop setup typically lands in the tens of thousands, while a full-service, well-equipped facility with showrooms and advanced testing gear can exceed half a million dollars. Your forecast should break out one-time investments—rent, renovations, equipment like hydraulic lifts, paint booths, wheel services, and diagnostic systems—against ongoing operating expenses such as salaries, utilities, insurance, parts inventory, and marketing. The forecast should also model different revenue scenarios: pure service fees, parts sales, or a hybrid model that pairs installation labor with a curated shop inventory of select modification components.

A robust business plan defines a sustainable revenue model. If you lean on service fees, consider tiered pricing that reflects complexity and expertise, while ensuring clear communication about what’s included in each tier. If you choose a product-plus-service approach, curate a carefully selected range of parts and brands that you can source reliably and install with confidence. The plan should also articulate a concrete marketing strategy that blends digital channels with local presence. Online, you’ll need a content approach that builds trust—before-and-after showcases, time-lapse build videos, and educational posts that demystify technical choices. Offline, opportunities exist in partnerships with local dealers, participation in car shows, and sponsorships of enthusiast clubs. The objective is not to flood the market with generic ads but to tell a story that matches the identified customer persona and demonstrates measurable value.

Operational discipline is the other pillar of the plan. Outline how a typical project moves from inquiry to delivery, the sequence of inspections and quality controls, and the warranties that accompany work. Define workflow steps to minimize rework and maximize consistency in outcomes, from intake and estimates to parts sourcing, build execution, testing, and handover. A well-designed workflow also clarifies lead times and capacity, helping you avoid overpromising and under-delivering—the most common strain on early reputations. In a market where trust is earned through workmanship and reliability, your ability to deliver predictable results matters as much as the car you help transform.

Funding considerations are inseparable from market intelligence and planning. Determine whether capital will come from personal savings, bank loans, or investor partnerships, and align funding choices with the business’s risk profile. A prudent rule of thumb is to maintain working capital to cover 6–12 months of overhead before the business generates consistent revenue. This reserve protects your operation during lean periods and gives you room to invest in higher-quality equipment or expanded services as demand grows. The planning process also helps you time equipment purchases and facility improvements to match expected demand rather than speculate on the best moment for investments.

Location and facility design are not afterthoughts; they are integral to the shop’s viability. Choose a site that maximizes visibility to your target customers and offers convenient access for customers who will bring vehicles in for upgrades or service. The space should be sufficient for storage, a production workshop, a showroom, and a customer lounge without crowding. Zoning considerations and environmental requirements become more than compliance hurdles—they influence your ability to operate smoothly and to scale. The plan should detail the criteria for site selection, including proximity to automotive hubs, access to shipping and receiving for parts, and the logistical ease of moving vehicles in and out of the shop. As you estimate space needs, remember that your revenue model may change as you expand; a scalable facility keeps doors open for new services without repeated relocations.

Licensing and regulatory compliance sit at the intersection of risk management and professional credibility. A well-founded plan accounts for the necessary licenses and permits before opening doors. This typically includes a business license, tax registration, and a motor vehicle repair permit. Depending on the specific services you offer, you may also need environmental permits or special certifications for certain modifications. By incorporating these requirements into the early phases of the plan, you prevent costly delays and demonstrate to customers and partners that you operate with accountability and high professional standards. A thoughtful approach to compliance also supports insurer confidence and the ability to offer warranties that stand up to scrutiny.

Building the team that will execute the plan is another critical investment. You’ll need skilled technicians with demonstrable expertise in your chosen niche, plus sales staff who understand technical details and can translate them into meaningful benefits for customers. The plan should outline a training calendar, certification expectations, and a culture of safety and continuous improvement. In an industry where technology evolves rapidly, ongoing education isn’t optional—it’s a competitive edge that protects your customers and your business.

Finally, the marketing and customer retention strategy must translate research into relationships. Use the market insights to craft messages that speak to the specific desires of your audience, whether that’s preserving car values, achieving peak performance, or creating an enduring aesthetic. A disciplined approach to marketing—combining social media, SEO, event participation, and strategic collaborations—creates a pipeline of inquiries that your capable team can convert. Equally important is a retention mindset: post-installation inspections, warranty support, and loyalty programs that reward repeat customers help you build a community around your shop rather than a string of one-off jobs. The strongest brands in car modification emerge not from a single spectacular project but from a pattern of reliable, high-quality outcomes that customers want to share with friends.

As you integrate these elements, a few practical connections keep the plan grounded. Data points gathered in your market research should map directly to the shop’s service menu, pricing, and capacity planning. If the research shows a large, enthusiastic base for performance builds, allocate budget and space for advanced tuning equipment and specialized technicians. If the emphasis leans toward aesthetic and value-driven upgrades, design a showroom experience that showcases finishes, materials, and craftsmanship. The plan must remain flexible enough to adjust to market feedback, while firm enough to guide decision-making in the face of uncertainty. When well-executed, market research and planning do more than reduce risk; they create a compelling narrative for investors, a clear roadmap for staff, and a credible promise to customers that your shop will deliver on its commitments.

For further context on how modifications can influence the value and resale potential of vehicles, you can consult resources such as car-modifications-and-resale-value. This strand of insight helps refine the pricing and service mix you offer, ensuring that the work you perform enhances rather than undermines a car’s long-term value. And as you build toward launch, remember that formal guidance on licensing and regulatory requirements is essential. The U.S. Small Business Administration (SBA) provides a reliable starting point for understanding the legal landscape and the steps needed to operate within the law. Access to practical, up-to-date guidance from reputable sources supports your planning and helps you shepherd the project from concept to a thriving, compliant business. See the SBA for authoritative licensing information and regulatory considerations.

Foundations in Regulation: Building a Car Modification Shop with a Solid Legal Structure and Licenses

Legal structure and licensing are not mere paperwork; they are the backbone of a durable, trustworthy modification shop. A well chosen legal foundation clarifies liability, taxes, financing, and day to day decision making. It also underpins the confidence of customers, partners, and insurers. When you begin with a solid framework, you create a platform from which everything else—facility, staff, and workflows—can reliably rise. This is not about compliance as a cost center, but about designing a business that can weather changing regulations and scale over time. The journey starts with choosing a formal legal entity and registering the shop’s identity in a way that aligns with local law and your service scope.

First comes the legal structure and business registration. The core idea is simple: select a legal form that limits personal liability while fitting your growth plans and tax obligations. In most markets you will register a business name with the local authority that oversees market entry and corporate naming. Alongside this, you apply for a business license whose scope explicitly includes automobile modification or vehicle repair. The language matters, because a broader or narrower scope can affect what you are allowed to do, and what counts as an approved activity for licenses, permits, and insurance coverages. The practical step is to ensure the official records reflect the services you intend to offer, from performance tuning to aesthetic enhancements, so that expansion into new capabilities does not require a fresh registration every time.

Next, understand the major operating licenses that turn registration into real capability. The motor vehicle repair license is the practical door cleaner to permit work on vehicles. It is typically issued by the local transportation bureau and confirms that your facility meets standards for equipment, workspace, and qualified personnel. Without this license, even legitimate repairs and tuning are technically outside the law, and work performed could be deemed illegal. An environmental impact assessment, or EIA, is increasingly a gatekeeper in modern workshops. If painting, welding, or other chemical processes are part of your service mix, you need an approved EIA that demonstrates how you manage waste and emissions. Safety cannot be an afterthought here; it is built into the permit process. The Fire Safety Inspection Certificate is another non negotiable item. It signals that your shop has proper fire prevention systems, clear exits, adequate storage for flammable materials, and appropriate safety signage. Fire protection is not merely ceremonial; it is a life saving discipline that auditors actively verify.

A further layer comes from the vehicle modification permit itself. In many jurisdictions, modifications that affect vehicle safety or registration status require explicit authorization from the public security or road traffic management authorities. This permit confirms that your staff, tools, and procedures are aligned with safety standards and regulatory expectations. The cumulative effect of these licenses is to create a controlled environment where modifications are performed responsibly and traceably. It also means that customers can expect consistent practices, clear warranties, and reliable documentation should issues arise after work is completed.

Facility and equipment requirements flow from these licenses. A compliant workshop is not a generic garage. It must be dedicated to vehicle work, well ventilated, and physically separated from administrative zones and public spaces. The workspace should minimize fire hazards, with proper storage for flammable liquids, and separate areas for testing, paint, and mechanical work. Clear safety zones, warning signs, and access controls are standard expectations. Equipment should be purpose built for a modification shop: alignment or wheel discipline systems, diagnostic platforms, welding and cutting rigs, and, where color is involved, spray booths and proper ventilation. Even if your start up is lean, you should design a layout that can evolve as you add services. A modest but scalable set of tools not only keeps you compliant but also signals to customers that you are serious about quality and safety.

Beyond the physical space, the people you hire and the systems you implement define how compliance becomes a daily habit. Technicians should hold relevant certifications and demonstrate a track record of responsible service. A safety officer on staff helps maintain a proactive safety culture—conducting regular inspections, reviewing procedures after incidents, and ensuring emergency plans are current. Internal systems underpin day to day operations: a robust quality assurance process, clearly stated warranty policies, and a disciplined approach to maintaining maintenance logs and technical files. Customer contracts and invoices should be precise, with scope, timelines, and costs clearly documented. An emergency response plan is not a formality; it is a living document you rehearse with staff so that in a real scenario everyone knows their role.

The additional considerations can shape the feasibility and speed of your launch. Some regions require a minimum level of registered capital to operate a modification enterprise, a threshold designed to ensure you have a cushion for equipment, safety, and working capital. If you install aftermarket parts such as turbochargers or control units, you must ensure they meet national safety and emission standards. This is not only about compliance; it is about reducing post installation failures and warranty disputes that can erode trust. A final component is testing and certification. When you create prototypes or push significant performance changes, plan for testing at a nationally accredited inspection body so you can document performance and safety claims. Even when a customer requests a bold customization, your process should demonstrate that you have tested and validated the modification against legal and safety standards.

All of this talk about structure and permits is ultimately about building confidence. Confidence that the shop can operate legally, safely, and predictably. Confidence that customers will share accurate information about their expectations, and that you can deliver results without risking fines, shutdowns, or legal battles. The practical path to achieving this begins with a tailored compliance plan, not a generic checklist. Start by listing the licenses you need, mapping each to the corresponding authority, and identifying the exact documentation you must prepare. Then align your facility’s design with the requirements of those licenses, ensuring appropriate separation of spaces, ventilation, and storage. Finally, translate compliance into culture by grounding every procedure in a written standard. The goal is to move from compliance as an external obligation to compliance as an internal discipline that guides every repair, upgrade, and interaction with customers.

To connect compliance with hands on practice, consider a pragmatic reference as you build out your capabilities. For example, when planning procedures for vehicle modifications, you can link to practical guidance on installation practices and safety considerations through a dedicated resource that explains how to install modifications on a car. This helps your team translate the regulatory framework into actionable steps on the shop floor. how to install modifications on a car.

As you prepare for inspections and audits, keep a straightforward record of every license, permit, and certification, plus the dates of renewals and the scope of each approval. Create a centralized compliance log that pairs each requirement with a responsible person and a renewal timeline. This simple system reduces the risk of lapses and makes it easier to scale as you add new services or expand to new locations. Finally, remember that the essence of legal structure and licensing is not danger management alone. It is the platform for sustainable growth, protective coverage for investment, and a clear path to delivering high quality, trustworthy car modifications to curious and demanding customers.

For those seeking more formal regulatory resources, you can explore official regulatory texts in the national framework. This external reference provides a definitive articulation of licensing, safety, and inspection expectations for vehicle modification enterprises. Official regulatory text: https://jtgl.mot.gov.cn/zhengce/fgwj/202503/t20250318_429876.html

Spotlight on Space: Strategic Location and Thoughtful Facility Design for a Car Modification Shop

Where a car modification shop sits and how its space is organized are more than logistical details; they form the silent framework of every service tier you offer. The right location isn’t just about footfall; it’s about the kind of client whose needs align with your specialty, and the facility design is the language you use to communicate safety, professionalism, and efficiency. In this chapter, we move through how a shop’s site and its physical footprint influence both day-to-day operations and the long arc of reputation, growth, and compliance. The aim is to craft a narrative of space that supports compelling, repeatable work—from high-performance tuning to aesthetic refinements—without compromising safety, legality, or the customer experience.

Choosing a site is a strategic negotiation between visibility, accessibility, and the density of automotive activity. Industry guidance emphasizes locating in places where traffic flows naturally and where potential customers are already thinking about vehicle upkeep or upgrades. A site near major auto sales centers, established repair districts, or even adjacent to a gas station can prime your visibility without the need for aggressive marketing push. The logic is simple: the moment a driver stops at a nearby facility for a routine service or a quick tire swap, your exterior presence—signage, a clean showroom, and a well-lit entrance—subtly invites curiosity about the other services you provide. Proximity to other automotive service providers also creates an ecosystem of referrals. If a customer is in for repairs yet aspires to a cosmetic upgrade, proximity to a capable shop can trigger a natural, trust-based transition from one specialist to another. This is the practical embodiment of network effects in a local market.

Beyond visibility, the logistics of access matter deeply. A site with ample parking space is non-negotiable. Clients often leave vehicles for extended work, and the ability to park multiple cars safely during a multi-day project speaks to the shop’s capacity and reliability. Easy access for both local drivers and out-of-town customers reduces friction at check-in and check-out, while convenient ingress and egress cut down on congestion in the workshop itself. Public transportation links, clear road access, and ample turning radii for larger vehicles all contribute to a smoother operational cadence. In short, your site invites customers to trust your process before they even step inside.

The footprint of the facility itself must match the scope of your ambition. National and regional standards, such as GB/T 16739 in certain contexts, set baseline expectations for the relationship between production spaces and support areas. A smaller operation might function well in the 100–200 square meter range, while a larger, more comprehensive shop could require 500 square meters or more. The floor plan should carve out a dedicated production and repair workshop, a clearly defined storage zone for parts and consumables, a customer-facing reception or showroom, and a separate office area for administrative tasks. This separation isn’t merely about order; it underpins safety and workflow. When staff can move efficiently between drafting, parts retrieval, and the testing area without traversing a crowded customer space, you reduce the risk of accidents and improve response times when issues arise.

Equipping the space with professional-grade infrastructure is another pillar of credibility. The core toolkit remains consistent across shops, whether you specialize in performance upgrades, chassis work, or premium finishes. A reliable vehicle lift is essential for access to undercarriage work and suspension tuning, while wheel mounting and balancing machinery support tire and wheel work that often accompanies performance packages. A paint booth and spray guns enable quality bodywork and finish applications, and comprehensive diagnostic tools let you validate performance changes and fault-detection with real data. Welding and cutting tools must meet the highest standards of safety, precision, and regulatory compliance. Calibration and testing devices should be certified by relevant inspection authorities to ensure measurements used in tuning and diagnostics are accurate. The upfront investment is substantial—often running from tens of thousands to well over six figures depending on scale and specialization—but the payoff is a facility that consistently delivers predictable results and reduces rework.

The layout of the space is as important as the equipment itself. A well-considered flow reduces excessive movement, minimizes cross-contamination between work areas, and keeps customer interactions calm and focused. A typical, practical arrangement places the reception and sales area near the entrance to welcome clients, with easy access to a parts storage room for quick retrieval during installations. The workshop, ideally separated by a robust barrier or far enough from the customer area to limit noise and fumes, houses the lifts, diagnostic bays, and specialized stations for tasks like exhaust work or engine tuning. Ventilation must be robust, particularly around paint booths and welding zones, to maintain air quality and comply with safety norms. Fire suppression systems should be integrated with every high-risk area, including spray booths and welding corners. An environmental perspective is essential: waste solvents, oils, and used fluids must be disposed of through approved channels, and the shop’s procedures should align with environmental regulations and any local permit requirements. In practice, this means documenting waste streams, having storage containers that meet containment standards, and arranging for periodic hazardous waste removal in line with local rules.

From a legal and operational standpoint, the setup phase is inseparable from compliance. A lease is not simply a financial instrument; it is the stage on which the business must perform reliably. A term of at least one year is often prudent, providing stability for license applications and supplier relations. The equipment list becomes the backbone of your registration dossier, and staff qualifications become a tangible promise to customers that your shop isn’t just a space but a competent team. The licensing pathway mirrors the discipline you apply to your physical space: your shop must be recognized as a Motor Vehicle Repair Business by the relevant transportation authority, and depending on the range of services offered, environmental impact assessments or hazardous materials handling licenses may be required. These steps are not bureaucratic speed bumps; they are the scaffolding that guarantees your operation meets safety, accountability, and service standards.

The interplay between location choice and facility design extends into the rhythms of daily work. A site that supports a steady cadence—arrival, intake, parts pickup, and multiple concurrent projects—helps your team maintain a consistent pace. It also makes it easier to train new technicians, because the physical cues of the space reinforce correct procedures. When a workshop feels orderly, technicians spend less time looking for tools, more time listening to customers, and more time delivering the results that distinguish a shop. And because the customer experience remains central, a thoughtful layout translates into a showroom that communicates capability: a clean, well-lit, and organized space signals reliability before a single word is spoken.

The strategic reader will recognize that selecting a location and shaping a facility are not one-off tasks. They are ongoing commitments that require you to observe market movements, regulatory updates, and shifts in customer expectations. As you grow, you may expand in ways that preserve your core strengths—a strong, visible location complemented by a workshop that scales without losing the safety margins and workflow efficiency that define quality work. If you seek a starting point for deeper practical insight into hands-on learning and skill-building that underpins the work you’ll bring to your customers, consider resources that distill the fundamentals of car modification learning and practice. How to Learn Car Modification offers foundational guidance that can inform both your technicians’ training plans and the way you present your capabilities to clients.

Ultimately, the right mix of strategic site selection and disciplined facility design doesn’t merely support the work—it elevates it. The most compelling proof of success is not a glossy brochure but the smooth, safe, and consistent delivery of modifications that meet customer expectations and regulatory requirements. Space, in this sense, becomes a partner in your business, enabling you to scale responsibly while preserving the integrity of every project—from a simple cosmetic upgrade to a comprehensive performance overhaul. The market rewards firms that respect space as a strategic asset, not as an afterthought. When you align location, layout, and licensure, you create a foundation that withstands the test of time and competition.

External resource: For regulatory context and broader policy alignment, refer to the official government framework that informs standards for transport and workshop operations. https://www.mot.gov.cn/zhengce/zhengceku/202512/t20251204_48678.html

Equipping the Workshop: Strategic Gear and Inventory Investment for Your Car Modification Shop

Equipping a car modification shop is more than filling a space with tools. It is about laying a reliable foundation that supports precision, safety, speed, and consistency in every project. The equipment you choose and the inventory you maintain set the pace of work, influence how you price services, and determine how well you can meet customer expectations. The core idea is simple: invest in a capable, scalable backbone, then build around it with smart inventory management, disciplined maintenance, and clear procedures that sustain quality over time. When you start from this vantage point, the rest of the business—customer experience, marketing, and growth—becomes a matter of execution rather than constant improvisation. A growing body of industry insight reinforces this view, noting that shops which prioritize robust equipment and a deep parts inventory tend to achieve higher customer retention and smoother throughput. That finding, paired with practical budgeting, helps frame a realistic path from concept to a functioning workshop that can handle both cosmetic work and technical modifications with confidence.

The first decision is space and layout, because the footprint of your operation dictates the kinds of equipment you can justify and the way you organize parts, tools, and vehicles. Most modern modification shops aim for a facility large enough to accommodate vehicle storage, a functional workshop area, a dedicated paint or finishing zone, a showroom or reception space for clients, and a safe, accessible flow from intake to completion. The numbers you’ll typically see range from roughly one hundred to five hundred square meters, depending on location, expected volume, and whether you intend to offer a broad suite of services or a focused niche. Beyond size, the space must be properly zoned for automotive use and configured to support safe mechanics and efficient production lines. A well-planned layout reduces unnecessary movement, speeds up installations, and makes it easier to train staff and onboard new equipment as the business grows.

At the heart of the workspace sits the core equipment that enables safe lifting, precise modification, and reliable diagnostics. Lifting systems form the backbone of any shop that intends to access undercarriage components, suspension, and exhaust systems. A high-quality lift, complemented by secure jack stands and a careful workflow for loading and unloading vehicles, ensures technicians can work efficiently while staying within safety standards. In addition to lifts, a range of ergonomic, general-purpose tools keeps the shop versatile. These include a complete set of hand tools, power tools, and storage solutions that prevent clutter and misplacement. The goal is not to own every possible tool but to curate a practical toolkit that supports the range of projects you plan to offer, from basic exhaust work to complex chassis tuning.

Cosmetic and performance work requires specialized equipment that often drives a larger portion of the initial investment. A dedicated paint area or a well ventilated, code compliant spray zone is essential for any aesthetic modifications. If a full paint booth is not immediately feasible, a properly equipped spray area with robust ventilation and filtration can still meet high standards for bodywork and coating. High-quality spray guns, well-maintained air compressors, sanding and finishing tools, and polishing machines are non negotiable for delivering professional finishes and durable results. For performance and mechanical tuning, diagnostic scanners, measurement devices, and calibration tools become critical. In many cases, this includes engine dynos or alternative testing rigs, precision torque wrenches, and specialized equipment for intake and exhaust work. The investment here reflects not only capability but accuracy, as precise calibrations directly affect performance outcomes and reliability.

Safety and environmental controls deserve the same emphasis as the tools themselves. A shop that embraces rigorous safety practices protects its people and its customers. Fire extinguishers, proper ventilation, fume extraction for welding and painting, and a thorough PPE program are baseline expectations. Equally important is a culture of clean operations, where waste streams are managed, materials are stored securely, and all actions align with established safety procedures. A well-structured safety framework reduces risk, minimizes downtime, and helps attract skilled technicians who value a responsible work environment.

When it comes to inventory, the strategy is not simply to stock a long list of parts but to curate a reliable pipeline of components that support quick turnarounds and consistent quality. Aftermarket parts constitute the core of what a modification shop sells and installs. You should aim to stock a curated range of high-demand performance parts, such as intake systems, exhaust components, suspension upgrades, and braking enhancements, while maintaining space for niche items that reflect your chosen specialty. Building strong supplier relationships is as important as the parts themselves. Consistent, quality supply reduces back orders, which in turn preserves customer trust and cycle time. Inventory depth matters because it enables you to complete more jobs without waiting for external shipments, a factor that directly improves customer satisfaction and cash flow.

Beyond performance-focused components, consider the interior and aesthetic elements that clients often request. A selection of custom trim pieces, wheels, steering wheels, seat covers, interior lighting, and other interior customization options broadens your service menu and strengthens cross-selling opportunities. Laziness in inventory can turn into missed revenue when a client asks for a seemingly small accessory and you cannot fulfill it on the spot. To keep this from happening, map typical modification packages against your stock list and align procurement cycles with your most profitable offerings. Consumables, adhesives, sealants, cleaning supplies, wiring harnesses, hoses, gaskets, and replacement parts used during installations are a steady need that should be replenished routinely. A practical rule is to maintain a buffer of critical consumables that minimizes the chance of a project stalling due to a missing item.

A modern modification shop also requires software and calibration tools that can handle the evolving complexity of contemporary vehicles. Diagnostics and programming interfaces, data logging, and software for calibration are essential to meet the expectations of customers seeking reliable, performance-focused modifications. While these tools can be a meaningful ongoing expense, they are indispensable for the accuracy and compatibility required by today’s vehicles. Planning for these costs up front, including annual subscription fees and updates, helps prevent surprises later in the life of the business.

Cost planning for equipment and inventory should be grounded in a realistic view of capital availability and depreciation. It is common to encounter upfront costs that range from modest to substantial, depending on scale and specialization. A practical approach is to phase the build, prioritizing items that unlock core capability first, then expanding to advanced equipment as demand and cash flow permit. The 2025 industry outlook reinforces the prudence of this approach, showing that shops that balance technology investment with a robust inventory achieve higher customer retention—roughly thirty percent more—compared with those that underinvest in either domain. This correlation between capability and loyalty can guide both budgeting and growth trajectories, ensuring the shop remains attractive to serious enthusiasts and everyday customers alike.

The procurement process itself deserves careful attention. Vet potential suppliers not only on price but on parts quality, lead times, warranty terms, and after-sales support. Establishing clear expectations about lead times, return policies, and bulk discount opportunities helps stabilize the supply chain and reduces the cognitive load on staff. An organized inventory system, whether a simple cloud-based solution or a more feature-rich platform, should track stock levels, usage rates, and reorder points. Regular audits, including spot checks of critical items, ensure the accuracy of stock data and prevent the cascading effects of miscounts that disrupt production. A disciplined approach to inventory reconciliations keeps margins healthy and minimizes slow-moving stock that competes for space and capital.

As you grow, the interplay between equipment and people becomes central. The equipment you select defines the skill set you hire and the training you provide. In turn, a capable team expands the shop’s capacity to handle more complex projects, which then justifies further investment in higher-end tools and expanded inventory. Training should be ongoing and hands-on, emphasizing safety protocols, correct usage, and maintenance routines that extend the lifespan of expensive gear. Clear operating procedures and checklists for each major task prevent variation in quality and help new staff ramp up quickly without risk to vehicles or people.

The human element is also part of the financial calculus. Maintenance costs for equipment, calibration of software, and parts turnover can accumulate. Build a maintenance calendar that includes regular inspections, service intervals, and scheduled calibration checks for diagnostic tools. This discipline reduces downtime, preserves performance, and protects the shop’s reputation for reliability. In practice, maintenance translates into predictable expenses and fewer emergency repairs, which in turn makes pricing and profitability easier to manage.

Finally, the chapter’s practical takeaway is that equipment and inventory are not merely costs to be managed but strategic assets that set the pace of your shop. The equipment defines what services you can offer, the inventory keeps those services flowing smoothly, and the processes around both deliver the consistent quality customers expect. In the long run, the alignment of space, tools, and parts—supported by disciplined procurement, training, and maintenance—creates a resilient platform for growth. When customers see that a shop can handle complex jobs with clarity, safety, and speed, they come back and share their experiences with others. For readers who want a concrete example of how to translate installation know-how into practical shop operations, see the guide linked here on how to install modifications for cars How to Install Modifications for Cars. This resource offers practical context that complements the strategic focus on equipment and inventory by illustrating the steps technicians follow to implement specific modifications.

As you prepare to move from planning to action, remember that equipment and inventory are interdependent pillars. Your layout supports the work you can perform, and your stock levels determine how often you can deliver completed projects without delay. Keeping the balance steady requires a combination of upfront vision, disciplined procurement, ongoing training, and a willingness to iterate. The next phase of opening a car modification shop will then build on this foundation by addressing legal structure, licensing, and the broader business model, ensuring that the venture remains compliant, financially viable, and ready to scale as demand grows. The equipment and inventory chapter thus serves as both a technical blueprint and a strategic compass, pointing you toward a shop that can consistently meet high standards while pursuing sustainable growth.

How to Open a Car Modification Shop: Building Your Expert Team

Success in opening a car modification shop rests as much on the people you hire as on the plans you draw. A shop is a living system where skilled hands meet disciplined processes, curiosity is tempered by safety, and the long arc of customer relationships begins with trust. The backbone of that system is your expert team: technically proficient technicians, a leader who can align them toward a shared vision, and a culture that grows through continuous learning. The market may reward a flashy portfolio, but sustainable growth comes from consistent execution—people who translate ideas into measurable outcomes for customers and the business. In this chapter we explore how to assemble and nurture a team that can deliver on that promise day after day, turning a bold business concept into a trusted neighborhood shop with a growing reputation for quality and reliability.

Technically Proficient Workforce

The core of your team starts with technicians who bring more than raw talent to the bench. A technically proficient workforce is built on formal training and substantial hands-on experience in automotive repair and modification. Ideally, modification technicians should have at least three years of automotive experience and a solid educational foundation in mechanical or automotive-related fields. This baseline matters because modifications touch complex systems—suspension, brakes, and engine management—which require careful interpretation of factory diagrams and aftermarket components. Your technicians should be comfortable translating design intent into safe, repeatable work. Beyond the core mechanical discipline, specialists such as audio and electrical technicians add deeper expertise. They must master electrical systems, acoustics, and clear client communication about desired outcomes, noise, vibration, and sound quality. The broad skill set protects the shop from quality drift and helps uphold a consistent customer experience.

Leadership

While individual skills matter, leadership is the decisive factor that translates talent into performance. The technical director bears responsibility for design integrity, safety compliance, and quality control across projects. This leader is often someone with a bachelor’s degree and several years of hands-on vehicle modification experience, plus fluency with CAD tools to visualize modifications before any work begins. A capable technical director coordinates workflows, sets design standards, and troubleshoots issues on the shop floor. They mentor younger technicians, align personal growth with the shop’s goals, and cultivate a culture that values precision and collaborative problem‑solving.

Training and Development Programs

Structured training and ongoing development are powerful investments in a field that evolves quickly. Workshops, online learning, and formal certifications create a learning spine for your organization. These programs promote new techniques, safety practices, quality control methods, and proper documentation. A shop that treats training as a core operating expense builds resilience and reduces knowledge gaps that can lead to safety incidents or dissatisfied customers. Training also supports retention when employees see a clear path for growth—new certifications, expanded responsibilities, and leadership opportunities.

Team Dynamics

Strong technical skills must be paired with effective teamwork. A successful shop cultivates collaboration, mutual respect, and shared goals. Clear objectives help technicians prioritize work without sacrificing quality or safety. Open communication channels between technicians, the technical director, and the service-advisor team prevent misinterpretations that could delay delivery. A positive work environment, reinforced by fair incentives and recognition, keeps motivation high and reduces turnover. When people feel valued as part of a wider mission, they bring a customer‑first mindset to every job.

Culture, Compliance, and Long-Term Growth

Beyond skills and culture, a high‑performing team anchors the shop to practical, repeatable processes. Documentation, safety protocols, and quality checks provide the scaffolding for scale. As the field shifts toward electrification and smarter vehicle systems, the team should adapt without sacrificing reliability. The leadership must ensure compliance with licensing and regulatory requirements, keeping the team current on relevant codes and training aligned with those standards. When the shop speaks with one voice about quality and safety, clients feel confident leaving their assets in your care.

Practical Path to Implementation

Turn these principles into everyday practice with a deliberate recruitment and onboarding approach. Define the competencies you value for each role, from senior technicians to entry-level apprentices. Use structured interviews and hands-on assessments to verify capability and problem‑solving approach. Onboarding pairs new hires with a senior mentor, accelerating practical learning and cultural alignment. Create a rolling schedule of in‑house workshops on core topics—suspension tuning, electrical diagnostics, safety protocols—paired with periodic external certifications. Establish a visible roadmap for advancement: what certifications are available, what projects showcase elevated responsibilities, and what performance milestones unlock new opportunities. Transparency clarifies expectations and signals to prospective hires that the shop is serious about growth.

The Glue Between Skill and Service

In the end, the strength of your expert team is the glue that binds strategy, service, and sales. A technically capable workforce attracts discerning clients who want reliable, high-quality modifications; a strong leader ensures client dreams become well-executed reality; and a culture of learning sustains momentum as the business grows. When the team operates with aligned goals, every project demonstrates precision and care, reinforcing referrals and repeat business. If you need a practical starting point for developing the core skill set and mindset, consider exploring introductory resources on car modification. External resources and professional training opportunities can further support your team’s trajectory, including international programs that expand what’s possible in automotive modification.

Final thoughts

Launching a car modification shop takes dedication, strategic planning, and a passion for automotive personalization. By navigating the essential steps—market research, compliance with legal requirements, creating a customer-friendly environment, equipping your shop effectively, and building a skilled team—you can create a thriving business that resonates with car enthusiasts and professionals alike. Remember, success won’t happen overnight; it will be the result of your commitment to quality and service. Embrace the journey ahead and fuel your entrepreneurial spirit in this exciting industry.