Car enthusiasts from all walks of life share a common quest: to enhance their rides, particularly when it comes to Chrysler vehicles. The world of automotive modifications offers immense possibilities, transforming vehicles into personal statements of style and performance. Modifications, whether purely aesthetic or deeply functional, can significantly change the dynamics of a car. In this in-depth exploration, we will delve into three crucial aspects of modifications on Chrysler cars: the aerodynamic enhancements that can boost performance, the integration and compatibility of interior upgrades to elevate driving experiences, and the trade-offs and considerations that accompany any customization journey. Through these chapters, the resonant benefits of upgrades will shine through, equipping you with insights to make informed decisions that align with your automotive ambitions.

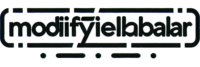

Winds of Efficiency: Real-World Aerodynamic Upgrades on Chrysler Cars and the Cadence of Performance Gains

Every drumbeat of automotive modification begins with a simple question: do design changes that alter the air around a car translate into something tangible on the road? For Chrysler-branded sedans and their family of performance-oriented variants, the answer—and the path to an answer—rests in how airflow is managed, how components interact with the car’s existing architecture, and how the vehicle is driven under real conditions, not just on a showroom dyno. Aerodynamics, when approached with care, becomes less about styling bravado and more about a coherent set of changes that align with the car’s physics. In this chapter we explore what really works when the goal is to improve efficiency, stability, and handling through aerodynamic enhancements, and how that translates into a broader performance story for Chrysler vehicles. We also consider the caveats—where the line between benefit and drawback lies, and how to navigate it with attention to quality, fitment, and system integration.

To begin, imagine a modern Chrysler sedan as a package engineered around a balance of front-end demand, midsection flow, and underbody management. The introduction of deliberate aerodynamic elements—such as a front splitter, a diffuser at the rear, side skirts, and underbody panels—operates like a set of carefully calibrated instruments that shape the boundary layer of air as it moves over, under, and around the car. The core aim is to reduce drag, improve downforce where it matters, and harmonize the vehicle’s cues with the demands of high-speed stability. The physics behind these upgrades is straightforward in principle: a cleaner, more directed air path reduces the energy required to push air aside, and more efficient usage of that air can translate into measurable improvements in fuel economy at highway cruising, along with enhanced stability at speed and more predictable handling in gusty or uneven lane conditions.

What does that look like in practice? A common approach involves adding a front splitter. This component extends forward of the bumper line, guiding air to follow the underside more smoothly and increasing front-end downforce slightly. The rear diffuser then takes the air that escapes from under the car and channels it upward and outward, reducing turbulent wake that can otherwise create drag and lift. Side skirts serve a related purpose by smoothing the air along the vehicle’s sides, reducing the wake generated by the wheel wells and lowering the amount of high-energy air that can reattach behind the car. Underbody panels close gaps and cover elements that would otherwise disrupt the air’s path, creating a more laminar flow under the chassis. Each of these parts is not merely a cosmetic add-on; when designed to integrate with the factory geometry and cooling systems, they become functional pieces of a broader aerodynamic strategy.

The performance narrative does not stop at the edges of the bumper and undercarriage. The real gains emerge when aerodynamic upgrades are part of a cohesive package that respects the vehicle’s powertrain, suspension, and cooling layout. When you combine measured aerodynamic aft- and underbody enhancements with calibrated suspension tuning and, where appropriate, engine optimization, the car’s overall efficiency and dynamic response improve. The air’s path is stabilized, the drag coefficient declines, and the car maintains a more confident grip on the pavement at higher speeds. Reports and tests in credible automotive literature show that even modest aerodynamic upgrades can reduce the coefficient of drag by a few points to as much as around ten percent in some configurations. Those figures translate into tangible benefits: better highway fuel economy, quieter operation at speed, and more consistent high-speed behavior in crosswinds or when the road surface offers varying textures.

To translate this into everyday driving, think of highway cruising first. When a car experiences less aerodynamic drag, the engine has to work less to maintain a given speed. The result is improved miles per gallon and, crucially, more stable wind pressure on the windshield and mirrors. The cabin feels calmer as wind noise drops, particularly above 60 miles per hour and beyond, where turbulent air previously teased the seals and contributed to a faint hum. The second layer of benefit shows up in handling: the front splitter and rear diffuser help maintain a more even distribution of downforce, which can translate into crisper steering feel and steadier cornering at speed. In a Chrysler sedan that glides between comfortable daily driving and spirited highway runs, these gains are not merely about speed smiles; they are about confidence, predictability, and the assurance that the car remains composed as weather and road surfaces change.

It is essential, however, to acknowledge that aerodynamic improvements do not automatically grant universal gains. The world of aftermarket parts is a mixed landscape. Some designs are impeccably engineered, with precise fitment that preserves cooling air intake, radiator clearance, and wheelarch geometry. Others are poorly conceived or poorly installed, and in those cases, the intended drag reduction can be offset by new forms of turbulence. A part misaligned with the vehicle’s body lines or one that alters the airflow to critical points—such as the radiator core, brake ducts, or A/C condenser—can compromise cooling or negate any drag-related savings. That is why, in practice, a well-executed package pays for itself in reliability and measurable performance, while a haphazard setup may offer a flashy look with little real-world return or, worse, hidden costs.

Compatibility with the car’s systems is another critical consideration. Aerodynamic components that sit near the front fascia, underbody, or sides must coexist with the car’s electronic stability programs, braking system, and sensors. Some modern Chrysler-branded sedans carry active or semi-active aerodynamic features in higher trims or performance-oriented variants. In those cases, aftermarket parts must be chosen and installed with an understanding of how that car’s control systems read wind and pressure to modulate stability. A thoughtful modification plan will consider not only the aesthetic and theoretical drag numbers but also how the piece rides within the car’s electrical and mechanical ecosystem. This is not an argument for cautious conservatism but a reminder that real performance is the product of harmony among multiple subsystems, each contributing to the whole.

The results can also be more meaningful when paired with complementary upgrades. Aerodynamics, by themselves, can lower drag and improve downforce; when paired with a tuned exhaust, a calibrated suspension, or even a strategic engine re-tune within safe and permissible boundaries, the overall package becomes more than sum of its parts. The improvements in aero efficiency complement power delivery and chassis balance. The car can accelerate more smoothly from mid-range torque, maintain momentum through corners with less margin for wind-induced drift, and sustain higher speeds with reduced fuel penalty. In the broader picture, the performance story a Chrysler owner can tell after such a package is not merely “I look faster,” but “I drive with steadier confidence and with more efficient energy use on the highway.”

Of course, the practical path to achieving these outcomes begins long before wrench meets metal. It starts with careful planning and a clear understanding of what you want the car to do. A genuine, well-documented modification plan will chart a sequence: select high-quality components whose geometry matches the car’s dimensions, verify that the alterations do not interfere with cooling or structural integrity, and arrange for precise installation by professionals who understand the interactions between air flow and underbody surfaces. It also means evaluating the cost of the project against the expected gains, including maintenance considerations. For example, side skirts and lower valences can attract dirt and require more frequent cleaning, especially along road edges and in climates where road salt or debris is common. The same holds for underbody panels that can accumulate grime; while these do not degrade performance in the moment, they can influence long-term airflow characteristics if they are not kept clean and intact. These practical realities remind us that modifications, to be worth the effort, must align with the owner’s goals and the car’s expected use.

What about the evidence that supports these claims? The broader automotive press, including respected outlets that routinely publish on the topic of modified vehicles, has discussed the measurable changes that aerodynamic upgrades can produce. While the exact figures vary based on model, configuration, and testing method, the consensus is that careful installations produce consistent gains in drag reduction and handling quality. In real-world testing, modest upgrades have delivered noticeable reductions in the drag coefficient and comfortable improvements in highway performance without compromising reliability when installation quality is high and parts are well-engineered for the target vehicle. The narrative across credible sources emphasizes the importance of selecting parts from reputable manufacturers and ensuring proper fitment, alignment, and integration with the car’s existing design philosophy. This is not a sales pitch for flashy add-ons but a sober reminder that the best results come from a well-integrated plan rather than a scattergun approach to “more aero is better.”

For readers seeking an actionable sense of scales and expectations, a practical reference point is the growing body of real-world tests in mainstream automotive media. These assessments can help frame what to anticipate in terms of drag reduction, fuel economy improvements, and stability gains. They remind us that while the highway data is valuable, the true value often shows up in the feel of the car at speed and in the way the airflow management translates into more consistent behavior in adverse conditions. In short, the most convincing case for aerodynamic upgrades in a Chrysler lineup is not that every tweak yields a dramatic, headline-grabbing improvement, but that a coherent, well-designed package can deliver measurable, confidence-boosting benefits that align with the car’s culture: a balance of comfort, efficiency, and dynamic capability.

For readers who want to explore practical, step-by-step considerations or see example planning in action, a useful resource to consult is the Car Modifications Guide. It offers structured guidance on how to approach such projects, including planning, fitment checks, and considerations that ensure compatibility with safety systems and daily usability. You can explore this resource here: Car Modifications Guide.

As we move from the theoretical to the hands-on realm, it is worth repeating a central caveat: the benefits of aerodynamic upgrades are maximized when the modifications are part of a coherent, purpose-built package. Random additions can upset the delicate balance of a car designed for comfort and efficiency. A thoughtful program respects the integration of cooling, braking, and suspension, and remains mindful of maintenance and drive conditions. The emphasis should be on quality, consistency, and alignment with the vehicle’s original design goals rather than merely chasing a lower drag number for its own sake. This is the essence of a practical, responsible approach to modifying Chrysler cars for aerodynamic and performance gains.

External resource for further context and testing data can be found at Car and Driver, which regularly evaluates modified vehicles and publishes insights into how real-world changes translate into performance. See https://www.caranddriver.com for current testing methodologies and results.

Do Modifications on Chrysler Cars Work: Integration and Compatibility of Interior Upgrades

Interior upgrades can refresh the feel of a car while delivering practical gains in usability and comfort, but they demand careful planning and a clear eye for integration. When considering modifications for a brand with a broad lineup, the most reliable path is to treat interior changes as systems rather than cosmetic layers. A well-executed interior upgrade respects the vehicle’s electrical architecture, its safety features, and the original interfaces that connect the driver to the car’s core functions. In this light, the question isn’t simply whether an upgrade can look or feel better; it’s whether it can work in harmony with the vehicle’s design, wiring, sensors, and control modules. The answer, more often than not, is yes, but only when the process is grounded in compatibility, quality, and careful installation practices.

Integration begins with a simple truth: modern interiors are a network. Not only do the panels and surfaces need to fit, but the underlying wiring, power supplies, and control signals must communicate without conflict. Common upgrades such as replacing trim components, upgrading seating materials, or adding ambient LED lighting can elevate the cabin experience, but they also ride atop the vehicle’s existing electrical tapestry. If a modification disrupts a circuit, interferes with a sensor’s reference, or encroaches on the wiring harness, it can trigger a cascade of issues—from dimmed dashboards to unresponsive displays or erratic lighting. In some cases, the effects extend beyond annoyance, touching the reliability of window regulators, seat adjustments, or even the behavior of climate and occupancy controls. The caution here is not to discourage personalization but to anchor it in a disciplined evaluation of how the modification interacts with the most sensitive, and often least visible, parts of the car.

Among the most critical considerations is compatibility with the car’s infotainment ecosystem. The onboard display, controls, and connectivity suite have matured into tightly integrated systems. Upgrades that affect the wiring harness, controller modules, or firmware can introduce software glitches, screen flicker, or loss of connectivity. For the interiors, this means that any change—whether it’s a different trim finish, a new steering wheel option, or upgraded seating materials—should be matched to parts that are designed for the exact model year and trim level. When parts are not calibrated for the vehicle’s specific electrical footprint, they can degrade the experience rather than enhance it. This is not just about keeping the electronics running smoothly; it’s also about maintaining the reliability and safety that come from sensors and control units that expect a certain electrical load and timing.

The practical takeaway is straightforward: invest in OEM-quality parts or certified aftermarket components that are designed for the precise year and trim. This does not only improve aesthetics or comfort; it preserves system integrity. For interior upgrades, these pieces are engineered to respect the car’s connector types, mounting points, and interference tolerances. A properly matched steering wheel, for example, is designed to mate with standard airbag deployments and compatibility with steering-position sensors and climate or audio controls. Likewise, upgraded seating materials should avoid creating new friction points or trap heat in unsafe ways, which can affect seat heaters or occupant-sensing modules. When substitutions are chosen with fit and function in mind, the gains can be meaningful—tactile quality, visual cohesion, and subtle ergonomic improvements—without compromising safety or reliability.

This emphasis on careful matching naturally leads to a broader question about the scope of interior upgrades. The interior is a relatively forgiving space for customization in terms of aesthetics; however, it is not immune to trade-offs. Leather or synthetic upholstery may be more lavish, but in sunny climates it can become susceptible to cracking or fading if UV exposure isn’t managed. Replacement trim, if not shaped to the original contours, can squeak, rub, or distort door seals. Even seemingly small changes—like a different finish on a door panel or a new type of decorative fascia—can alter the way nearby components align, which may lead to rattles or gaps that degrade the perceived quality of the cabin. The implication is that every upgrade should be installed with an eye toward long-term behavior, not just immediate appearance. It’s not merely about fitting a piece; it’s about ensuring the piece can withstand temperature swings, vibration, and the daily wear of a driver’s routine.

For those who prioritize a cohesive, clean integration, the installation process becomes as important as the component itself. Working with experienced technicians who understand the vehicle’s architecture can be the difference between a seamless upgrade and a cascading set of problems. Installation guides that are verified and model-specific are invaluable. They help ensure that the chosen parts connect to compatible harnesses, sit within the same kinematic envelope, and do not apply unintended strain to connectors or fasteners. A careful installation also guards the vehicle’s modular nature. Modern interiors often rely on modular panels that can be removed and reinstalled without damage when the car is serviced. A misfit upgrade can make future service more difficult, potentially complicating airbag system access, sensor calibration, or trim removal. In short, the value of an interior modification is maximized when it respects the vehicle at the systemic level—when it behaves like it was always part of the design, not as a temporary add-on.

The role of the installer cannot be overstated. A qualified technician will assess electrical load, current draw, and potential interference with CAN bus networks or other communication pathways in the vehicle. They will verify that the upgrade does not alter wake/sleep behavior of modules, does not create ground loops, and does not inadvertently adjust safety-related parameters. The best installers will also guide the owner through a testing protocol that checks everything from power delivery and lighting to the responsiveness of the infotainment interface after the modification. This approach reduces the risk of latent issues that might emerge after a drive cycle or a change in weather conditions. It also helps ensure that the upgrade remains robust in normal usage, and that it does not require frequent corrective maintenance.

From the perspective of practical outcomes, one of the most meaningful benefits of interior upgrades is the tactile and visual harmony they can create. Upgrades to seating materials can elevate comfort on long trips, while enhanced lighting can improve cabin ambience and reduce eye strain at night. Replacing or refining trim pieces can unify the look of the cabin, making a vehicle feel newer and more tailored to the driver’s preferences. And when these interior elements are chosen with attention to how they are anchored and powered, the improvements are not simply skin-deep; they support a coherent and effective user experience that complements driving performance rather than distracting from it.

Yet it would be remiss not to acknowledge the real vulnerabilities that can accompany modifications. Vehicles with a history of fragile interior components—such as window regulators or aging interior lighting circuits—are more likely to exhibit issues if the upgrade involves additional electrical demands or mechanical strain. In such cases, even a seemingly simple upgrade, like accent lighting that draws on the same circuit as interior lighting, can create flicker or voltage fluctuations if the electrical supply is already near its limit. The practical counsel is to treat the upgrade plan as a system audit. Verify the health of the existing components, particularly those with a known track record of weaknesses in older or higher-mileage examples. If the baseline is robust, an upgrade performed with a careful, model-specific approach can yield reliable, durable improvements. If the baseline shows signs of strain, it is wise to address those issues first before layering on new components.

Car owners who anticipate long-term ownership should also weigh how modifications affect resale value and insurance considerations. Interior upgrades that are tasteful, well-constructed, and properly documented can preserve or even enhance value by signaling a cared-for, up-to-date cabin. But poorly executed changes, or modifications that require invasive disconnection of factory wiring or that appear non-standard in the eyes of a future inspector, can complicate resale or trigger questions from insurers. The safest path is to document every part, its origin, and the installation steps. Retain receipts, part numbers, and installation photos. When possible, seek parts that come with warranties and are supported by installation guides that are specific to the model year and trim. By aligning with these standards, interior renovations are more likely to be viewed as legitimate upgrades rather than as risky, unverified alterations. As with any carefully chosen upgrade, this approach can help preserve the car’s original reliability while still delivering the enhanced experience owners want.

A practical way to ground this discussion is to consider the ecosystem of resources that guide interior upgrades. Model-specific communities, professional installers, and service manuals offer a set of guardrails that help owners navigate compatibility challenges. It is especially important to rely on reputable sources and guides that emphasize integration with the car’s original electrical and control systems. In the realm of interior electronics and lighting, for example, verified installation guides can provide step-by-step directions that minimize the chance of wiring mistakes or software conflicts. When a modification touches the infotainment domain—think screens, menus, or connectivity—it becomes even more essential to align with guides that address software versions, firmware dependencies, and the specific wiring harness configurations involved. This alignment is the key to avoiding the type of software glitches or hardware incompatibilities that can degrade the user experience and erode confidence in the modification’s reliability.

For readers seeking concrete, hands-on direction on how to approach interior modifications, a practical starting point is a dedicated guide that walks through installation steps for common interior upgrades. The guide emphasizes model-specific fitment, wiring considerations, and testing procedures to ensure a clean, stable, and safe result. By following such a resource, owners can approach upgrades with a disciplined plan rather than a series of ad hoc changes. For readers who want a direct route to practical installation steps, consider the tutorial that focuses on interior modification procedures. This resource offers a grounded, step-by-step framework that aligns with the best practices described here and helps ensure a cohesive cabin upgrade that respects the vehicle’s design and safety constraints. How to Install Modifications for Cars

In closing, interior upgrades can work well when they are anchored to compatibility, quality, and professional execution. The aim is to improve comfort and aesthetics without sacrificing reliability, safety, or the ability of the car to perform as designed. When a modification is chosen with exacting attention to the vehicle’s year, trim, electrical architecture, and service expectations, the payoff can be substantial. The cabin becomes a more personal space, the driver remains connected to the car’s core functions, and the overall ownership experience improves rather than complicates. For owners who wish to explore interior upgrades with a careful, informed approach, the path is clear: respect the integration points, choose components designed for exact fit, lean on qualified installation guidance, and test comprehensively to confirm that the upgrade operates within the same dependable design envelope that makes driving a modern vehicle enjoyable. For extended reading on how different interiors integrate with vehicle systems and the real-world implications of modifications, see a detailed external automotive review and discussion on cabin design and reliability. https://www.caranddriver.com/chrysler-200-review

Do Modifications on Chrysler Cars Work: Balancing Style, Safety, and Warranty in Customization

Modifying a Chrysler car can offer meaningful benefits when done thoughtfully and with respect for the car’s systems. The key is to balance style, performance, reliability, and warranty implications. With careful planning, changes can enhance aesthetics and functionality without sacrificing daily usability. This overview highlights practical considerations and a disciplined approach to customization.

A popular entry point is exterior styling, such as grilles, spoiler lips, and trim accents. These parts influence airflow and appearance, and when chosen with proper fitment and quality materials, can improve the car’s stance while maintaining compatibility with sensors and cooling. It is important to verify fitment across model years and ensure revisions do not obstruct camera or radar sensors.

Warranty and maintenance are central to the decision. Factory coverage varies by market and model, and non OEM parts or modifications can affect warranty if failures are linked to the change. Documenting the installation, using reputable parts, and selecting brands with clear compatibility guidelines can mitigate risk. For those who rely on long-term ownership, a conservative approach—prioritizing OEM accessories or well-documented aftermarket parts—often offers a safer balance of value and peace of mind.

Interior upgrades, such as refined materials or updated controls, can personalize the experience without compromising safety. Align parts with Chrysler’s specifications to preserve airbag timing, steering wheel controls, and ergonomic integration. The goal is a cohesive upgrade that feels like a natural extension of the factory design.

In short, modifications on Chrysler cars work best when guided by a clear objective, careful sourcing, and professional installation. The most durable results respect the vehicle as a system, preserve key safety and reliability features, and stay reversible where possible to preserve resale value.

Final thoughts

In conclusion, modifications on Chrysler cars can be a pathway to both performance enhancements and aesthetic upgrades. The right modifications can effectively elevate your vehicle, allowing for a unique expression of personality while improving performance capabilities. The insights gained from exploring aerodynamic enhancements, compatible interior upgrades, and the essential trade-offs serve as a guide for hobbyists and professional tuners alike. By prioritizing quality parts and installations, one can ensure that their customization journey is both a visually and functionally rewarding experience. Take the knowledge garnered here and apply it as you embark on your own modification adventures, ensuring that your Chrysler not only meets but exceeds your automotive aspirations.